Liebherr claims that its new wheeled loader range will offer high operating efficiency. High performance with fast cycle times are said to be matched with precise control at low speeds as well as low fuel consumption and running costs. Durable and reliable, the machines are said to be heavily built to cope with tough site conditions.

The most innovative feature of the machines is the new driveline system, which combines Liebherr’s trademark hydrostatic system with a mechanical drive developed by ZF. Acc

March 15, 2016

Read time: 2 mins

The most innovative feature of the machines is the new driveline system, which combines Liebherr’s trademark hydrostatic system with a mechanical drive developed by ZF. According to Liebherr this will make the new loaders more fuel efficient than any other models available.

The hydrostatic drive works for forward and reverse and at low speeds where precision is required. At full speed for longer load and carry cycles, the machines switch over completely to the constantly variable transmission (CVT) mechanical drive. When operating at speeds in between, the onboard electronics govern precisely how much of the drive is through the hydrostatic and CVT systems. This is monitored and balanced continuously to optimise performance, boosting efficiency.

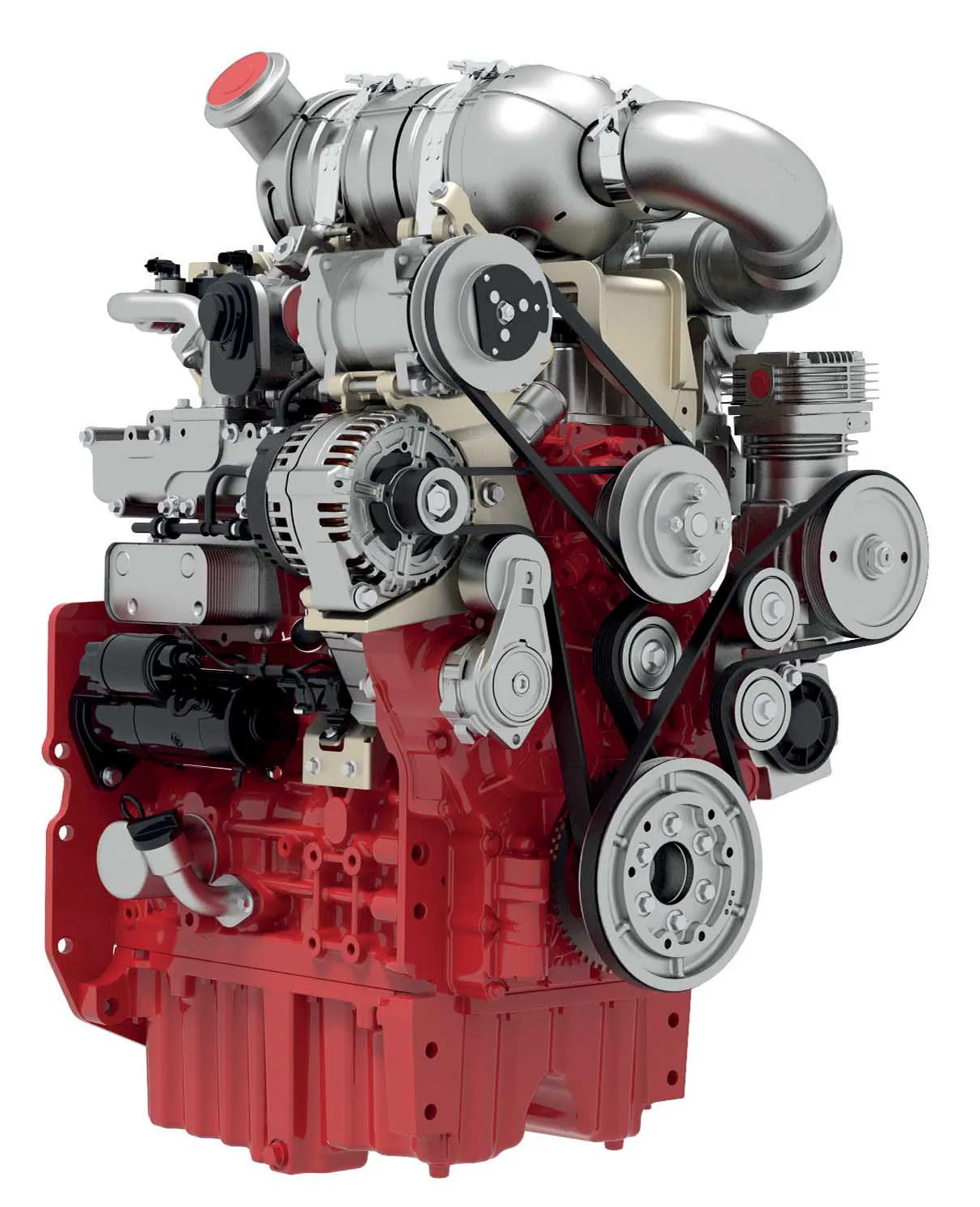

The low emission engines are also Liebherr units and have no need of EGR systems. This is said to reduce cooling requirements and also boost operating safety in applications where the heat generated by an EGR system poses a potential risk.

Customers can select either z-bar linkages or parallel (industrial) linkages to suit the application and at no extra cost. A range of bucket options is also available. With the engines mounted behind the back axle, weight distribution is also said to be optimised for loading operations. Other benefits include advanced cooling systems, improved operator comfort and visibility and easy maintenance procedures.

All videos