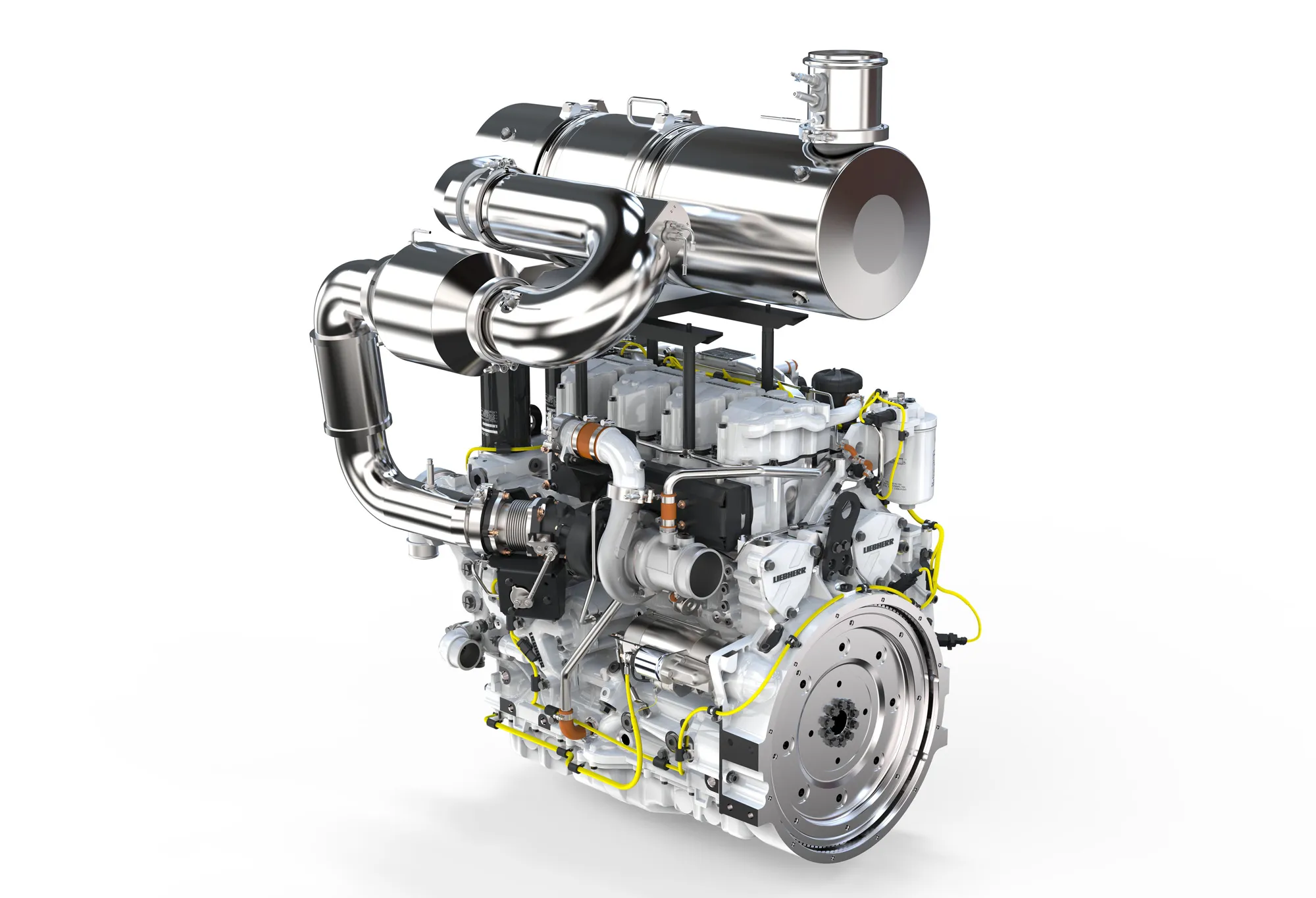

Liebherr and the Russian company Kamaz have signed a contract to develop and manufacture a range of six-cylinder diesel engines with 12litre displacement. The engines are tailored by Liebherr to meet specific requirements from Kamaz.

At the same time, the contract includes a complete solution for the construction of an engine production and assembly line as well as respective quality assurance within Kamaz's production.

The main factors for Kamaz's decision to work with Liebherr as a development part

May 14, 2014

Read time: 2 mins

At the same time, the contract includes a complete solution for the construction of an engine production and assembly line as well as respective quality assurance within Kamaz's production.

The main factors for Kamaz's decision to work with Liebherr as a development partner were said by the firm to be, on one hand, the modern engine concept with a good power to weight ratio and, on the other, the impressive strategy to comply with the emissions directives of Euro 5 and Euro 6. The 6-cylinder engines with 12litre displacement are built in four performance categories. For low fuel consumption, they are equipped with common rail injection and motor control units from Liebherr. The tried and tested engines from Liebherr are specifically adapted for use in Kamaz trucks and special vehicles for the oil and gas industry. Aside from diesel engines, Liebherr also offers a gas engine for mobile vehicles based on the jointly developed engine.