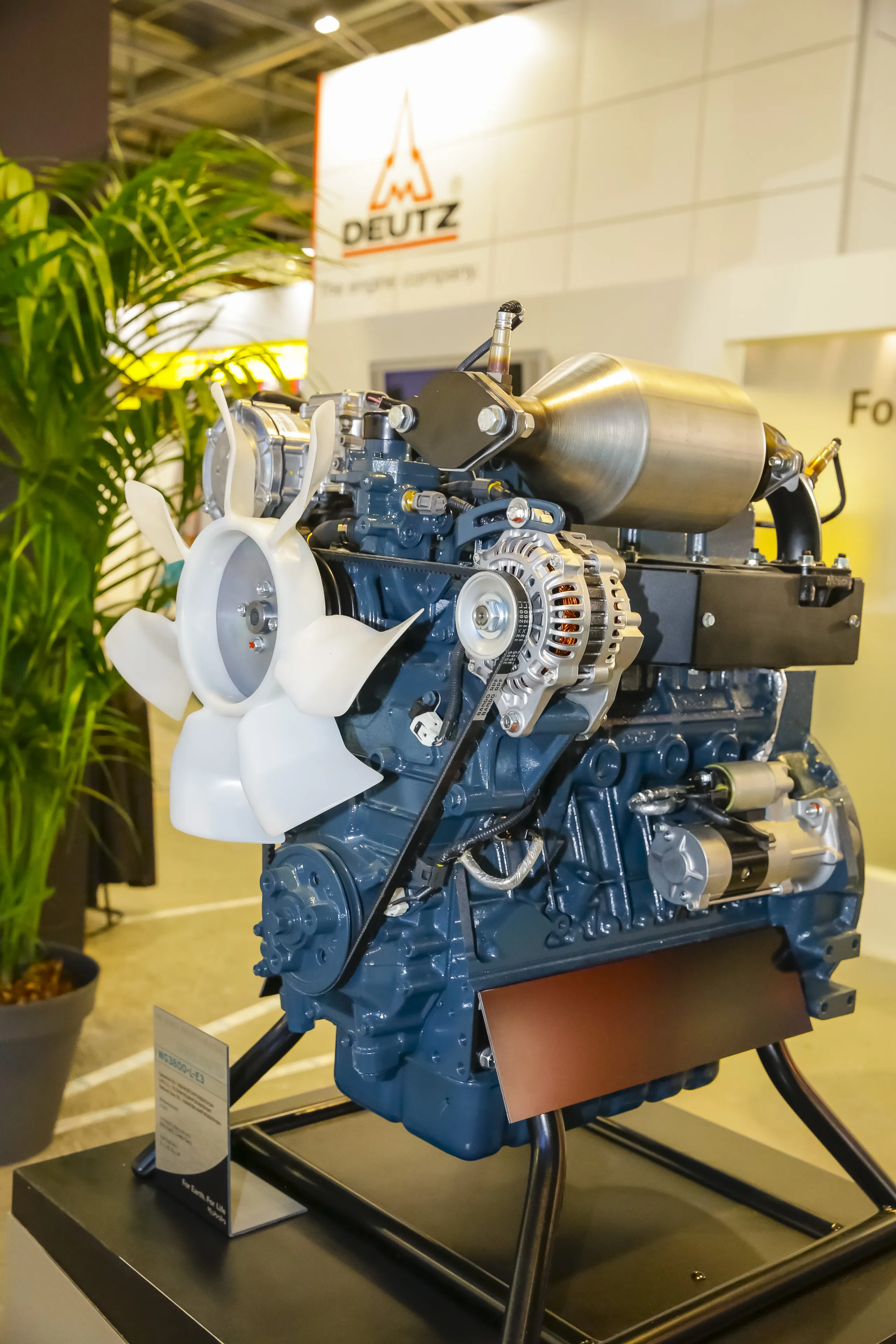

Kubota claims that its new WG3800 engine offers low emissions and high performance. This is the latest addition to the firm’s WG series of industrial water-cooled, spark ignition engines. The 3.8litre WG3800 will be offered in LPG, petrol, natural gas and a dual fuel version that can run on either petrol or natural gas. This engine will be supplied to manufacturers for construction and industrial equipment.

January 6, 2017

Read time: 2 mins

Kubota says it has taken measures to comply with the various emission requirements in designing this new spark ignition engine. The WG series has the same industrial footprint as the diesel line-up. The displacement of the existing models ranges from 0.74-2.5litres, and has moved upwards with the addition of the new3.8litre WG3800. This new unit offers a range of spark ignition variants for construction and industrial equipment manufacturer for use in various applications such as forklifts and generators.

Kubota has developed the WG3800 meeting the latest emission regulations in the United States, Europe, and Japan. Based on the V3800 diesel engine, the firm has developed a combustion chamber, fuel and ignition system dedicated for spark ignition. The LPG variant is rated at 70kW, with 65kW for the petrol model, 63kW for the natural gas version and 66/65kW for the dual fuel unit.