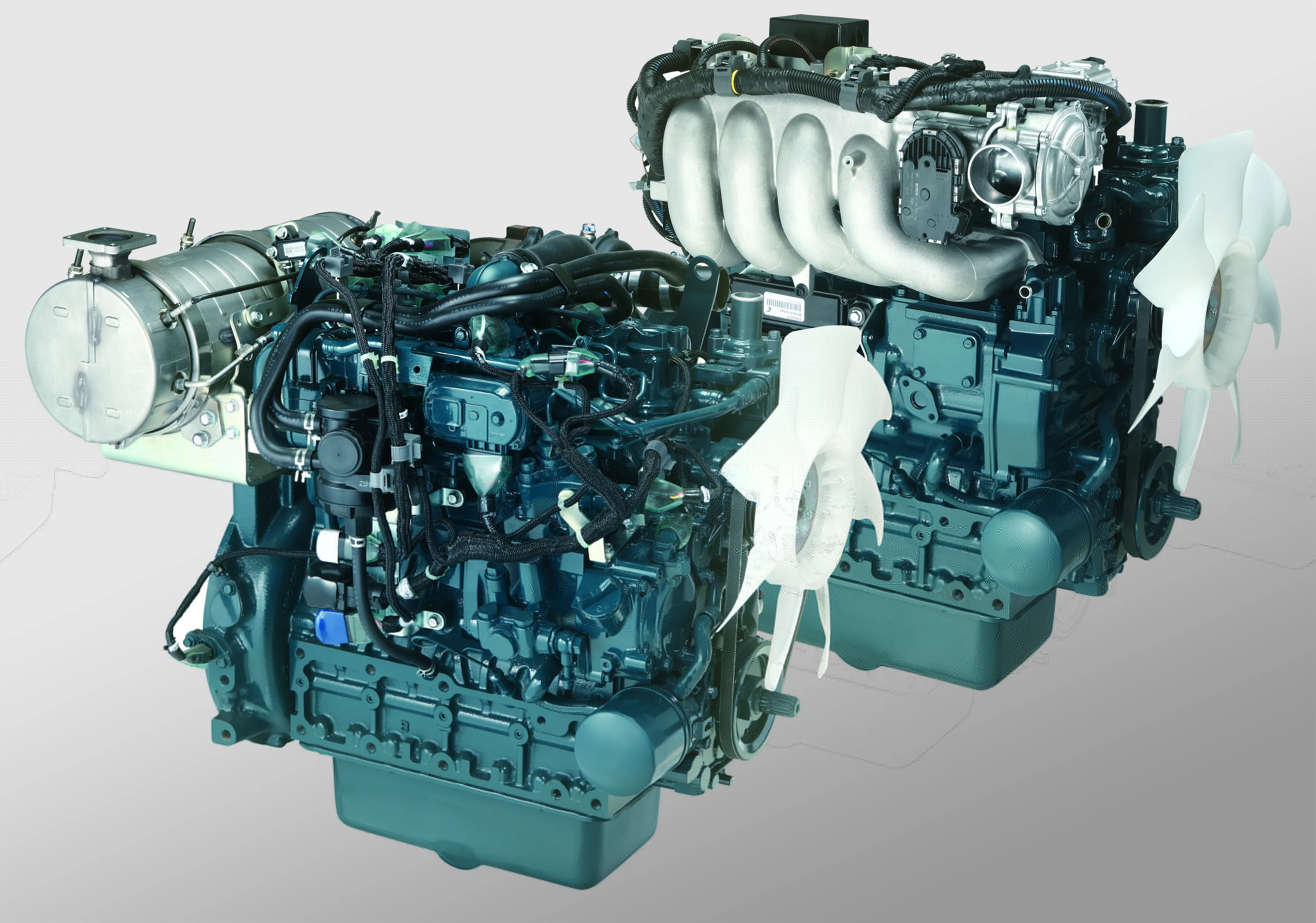

Kubota says it is offering a range of engines that can run on various alternative fuels. These can be used instead of diesel fuel engines. As an alternative to diesel, the machinery manufacturer has the choice between power units with similar dimensions (footprint) fuelled by petrol (gasoline), natural gas, liquefied petroleum gas (LPG) or compressed natural gas (CNG). These alternative fuel type engines are likely to be cheaper to buy and run than future diesel engines.

March 21, 2016

Read time: 1 min