A key launch for Komatsu comes in the shape of its new Dash 11 series excavators, with the PC240LC-11 and PC490LC-11 both making their debut at Conexpo 2014. The PC240 weighs from 24.7-25tonnes depending on specification, with power from a 132kW diesel, while the PC490 weighs from 47.9-50tonnes depending on specification and is driven by a 268kW diesel.

January 6, 2017

Read time: 2 mins

A key launch for 2300 Komatsu comes in the shape of its new Dash 11 series excavators, with the PC240LC-11 and PC490LC-11 both making their debut at Conexpo 2014.

The PC240 weighs from 24.7-25tonnes depending on specification, with power from a 132kW diesel, while the PC490 weighs from 47.9-50tonnes depending on specification and is driven by a 268kW diesel.

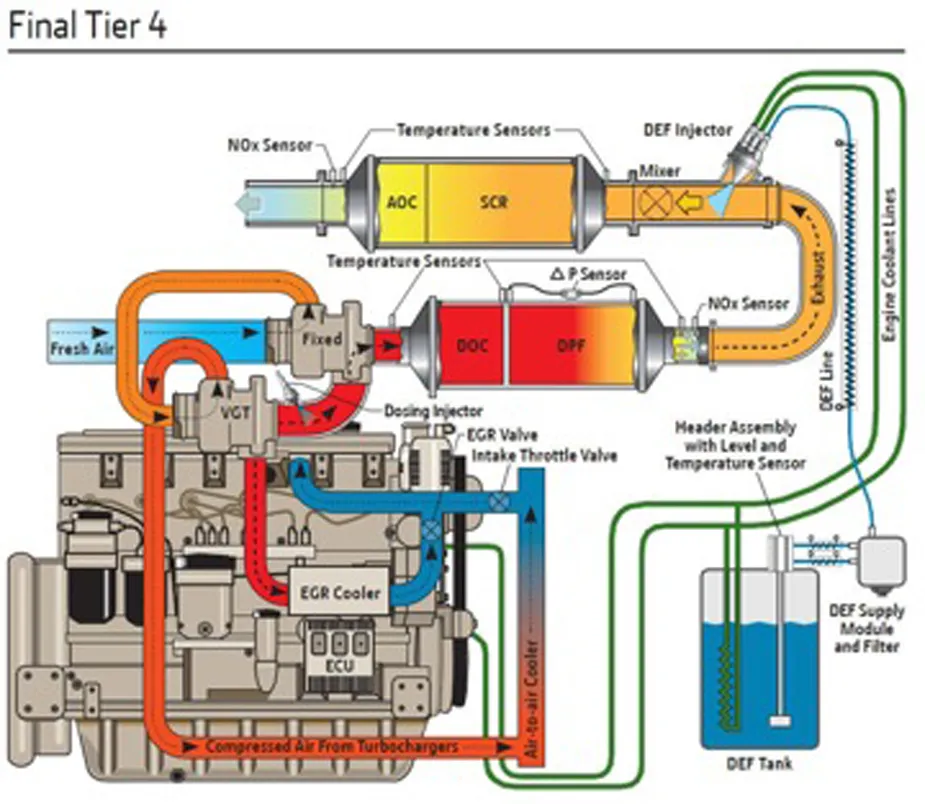

Major developments include the Tier 4 Final compliance power units offered on both models, with the engine systems fully integrated into the operation of the machines for greater overall efficiency. Emissions and fuel consumption have been reduced, while performance and response have been increased.

The PC490LC-11 is said to be up to 7% more fuel efficient than the model it replaces for example and the KOMTRAX remote monitoring systems allow a customer to keep a close watch on operating parameters remotely, through a GSM connection. This monitoring includes the diesel exhaust fluid, as well as watching fuel levels and operating hours, while an auto idle function will further cut fuel consumption.

Major components such as the engine, hydraulic pumps, motors, and valves are designed and manufactured by Komatsu. This integrated design uses a closed centre load sensing hydraulic system, which boosts efficiency by matching engine speed against hydraulic pump output for both light and heavy-duty applications. Other improvements in the hydraulic system reduce hydraulic loss, boosting efficiency.

The high visibility cab is ROPS certified cab and features a reinforced box structure framework, while being mounted on viscous isolation dampers to cut vibration levels. The operator can up to six working modes to match machine performance to the application. Other improvements include better service access to reduce downtime, as well as better stability. For the PC490LC-11, a variable track gauge option increases lateral stability and lift capacity by up to 10%.

%$Linker:2 Asset <?xml version="1.0" encoding="utf-16"?><dictionary /> 2 48977 0 oLinkExternal www.komatsu.com Visit Komatsu Website false /EasySiteWeb/GatewayLink.aspx?alId=48977 false false %>

The PC240 weighs from 24.7-25tonnes depending on specification, with power from a 132kW diesel, while the PC490 weighs from 47.9-50tonnes depending on specification and is driven by a 268kW diesel.

Major developments include the Tier 4 Final compliance power units offered on both models, with the engine systems fully integrated into the operation of the machines for greater overall efficiency. Emissions and fuel consumption have been reduced, while performance and response have been increased.

The PC490LC-11 is said to be up to 7% more fuel efficient than the model it replaces for example and the KOMTRAX remote monitoring systems allow a customer to keep a close watch on operating parameters remotely, through a GSM connection. This monitoring includes the diesel exhaust fluid, as well as watching fuel levels and operating hours, while an auto idle function will further cut fuel consumption.

Major components such as the engine, hydraulic pumps, motors, and valves are designed and manufactured by Komatsu. This integrated design uses a closed centre load sensing hydraulic system, which boosts efficiency by matching engine speed against hydraulic pump output for both light and heavy-duty applications. Other improvements in the hydraulic system reduce hydraulic loss, boosting efficiency.

The high visibility cab is ROPS certified cab and features a reinforced box structure framework, while being mounted on viscous isolation dampers to cut vibration levels. The operator can up to six working modes to match machine performance to the application. Other improvements include better service access to reduce downtime, as well as better stability. For the PC490LC-11, a variable track gauge option increases lateral stability and lift capacity by up to 10%.

%$Linker: