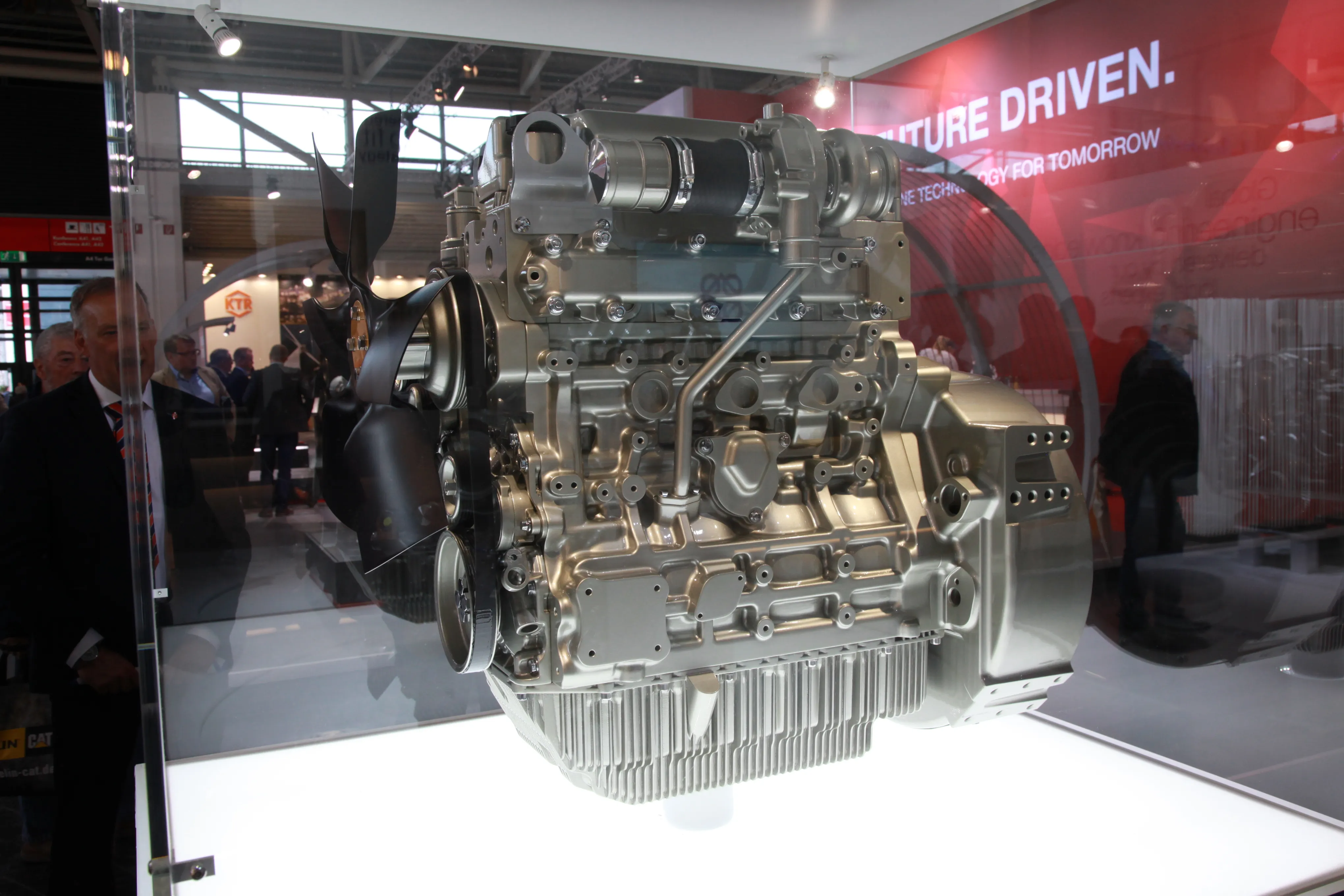

KOHLER unveiled its new KDI 3404 engine at bauma 2014 held in Shanghai, China. A 3.4litre (3359cc) unit it is available in two models with a total of four different power outputs. It is aimed at the market's increasing demand for smaller engines with high productivity.

Use of technologies such as high-pressure (2000 bar) Common Rail injection system and electronically controlled EGR valve to recirculate exhaust gases allow more efficient combustion so reducing fuel consumption and giving power levels eq

January 6, 2017

Read time: 2 mins

Use of technologies such as high-pressure (2000 bar) Common Rail injection system and electronically controlled EGR valve to recirculate exhaust gases allow more efficient combustion so reducing fuel consumption and giving power levels equivalent to engines of larger displacement. Thanks to clean combustion no diesel particulate filter (DPF) is required so allowing the engine to be more compact.

KOHLER claims the KDI 3404 uses 10% less fuel than other engines in its category. With best in class power and torque up to 15% better productivity can be achieved by machines it powers over those using the closest competitor.

The standard KDI 3404TCR (turbo common rail) is rated at 55.4kW with peak torque of 375Nm and is compliant to Stage IIIB Tier 4 final.

The other model KDI 3404TCR-SCR has a SCR (selective catalyst reduction) system to reduce NOx gases in the exhaust and complies to Stage IV Tier 4 Final. It is available in three power outputs. The 75kW version has peak torque of 475Nm. There is a 90kW version with 480Nm and the most powerful is 100kW with 500Nm.