Keestrack is announcing its new track-mounted cone crusher H4 as the first of its kind in the world.

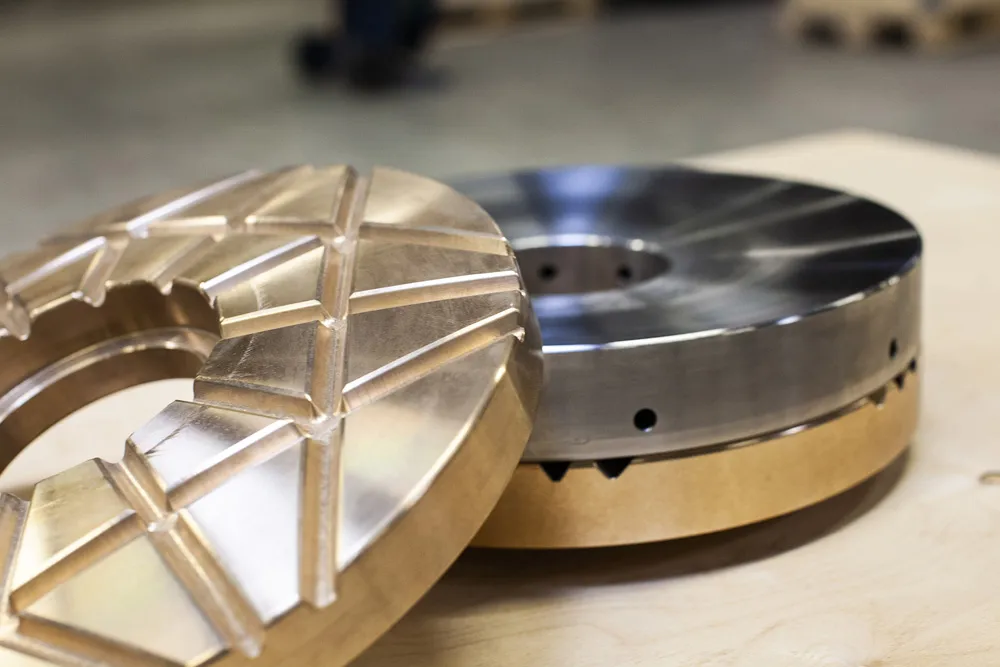

At the heart of the model, designed for high-value secondary or tertiary production in the 120-200tonnes/hour performance range, is the proven cone crushing technology of a world-renowned supply partner, with whom the company is working closely to optimise its machines for deployment in mobile situations.

According to Keestrack, a pioneering factor has been the advanced solutions in crusher control an

March 15, 2016

Read time: 2 mins

At the heart of the model, designed for high-value secondary or tertiary production in the 120-200tonnes/hour performance range, is the proven cone crushing technology of a world-renowned supply partner, with whom the company is working closely to optimise its machines for deployment in mobile situations.

According to Keestrack, a pioneering factor has been the advanced solutions in crusher control and monitoring systems, directly impacting output capacity and product quality.

As the successor to the Galleon series, the Keestrack H4, which has a transport weight of 35-50tonnes, has been given a completely new frame design, enabling the incorporation of efficient pre and post-screening units but also the use of innovative drive technologies.

For example, the Keestrack says the H4 is the world’s first mobile cone crusher with a three-deck post-screening module with an oversize material recycler for the production of three high-grade end products in one pass.

Keestrack is offering a choice of three economical drive combinations: direct diesel drive of the crusher with electrical or electro-hydraulic peripherals, such as conveyors and screen units, or the fully hybrid/plug-in version with similar electrical crusher drive via on-board diesel generator or mains power.