With transport weights of less than 30tonnes are the jaw crusher Keestrack B2 (former Argo), with a jaw width of 1,000mm, and the crusher unit Keestrack R4 (former Destroyer 1011) with add-on screener and oversize material recycler.

This also applies to the Keestrack R8 top crusher unit (former Destroyer 1313), that is presented as a highly productive mobile solution in the output range of 450tonnes/hour.

“As is the case for all Keestrack crusher units, the heavy construction of the 1,250mm wide roto

January 6, 2017

Read time: 2 mins

With transport weights of less than 30tonnes are the jaw crusher 2992 Keestrack B2 (former Argo), with a jaw width of 1,000mm, and the crusher unit Keestrack R4 (former Destroyer 1011) with add-on screener and oversize material recycler.

This also applies to the Keestrack R8 top crusher unit (former Destroyer 1313), that is presented as a highly productive mobile solution in the output range of 450tonnes/hour.

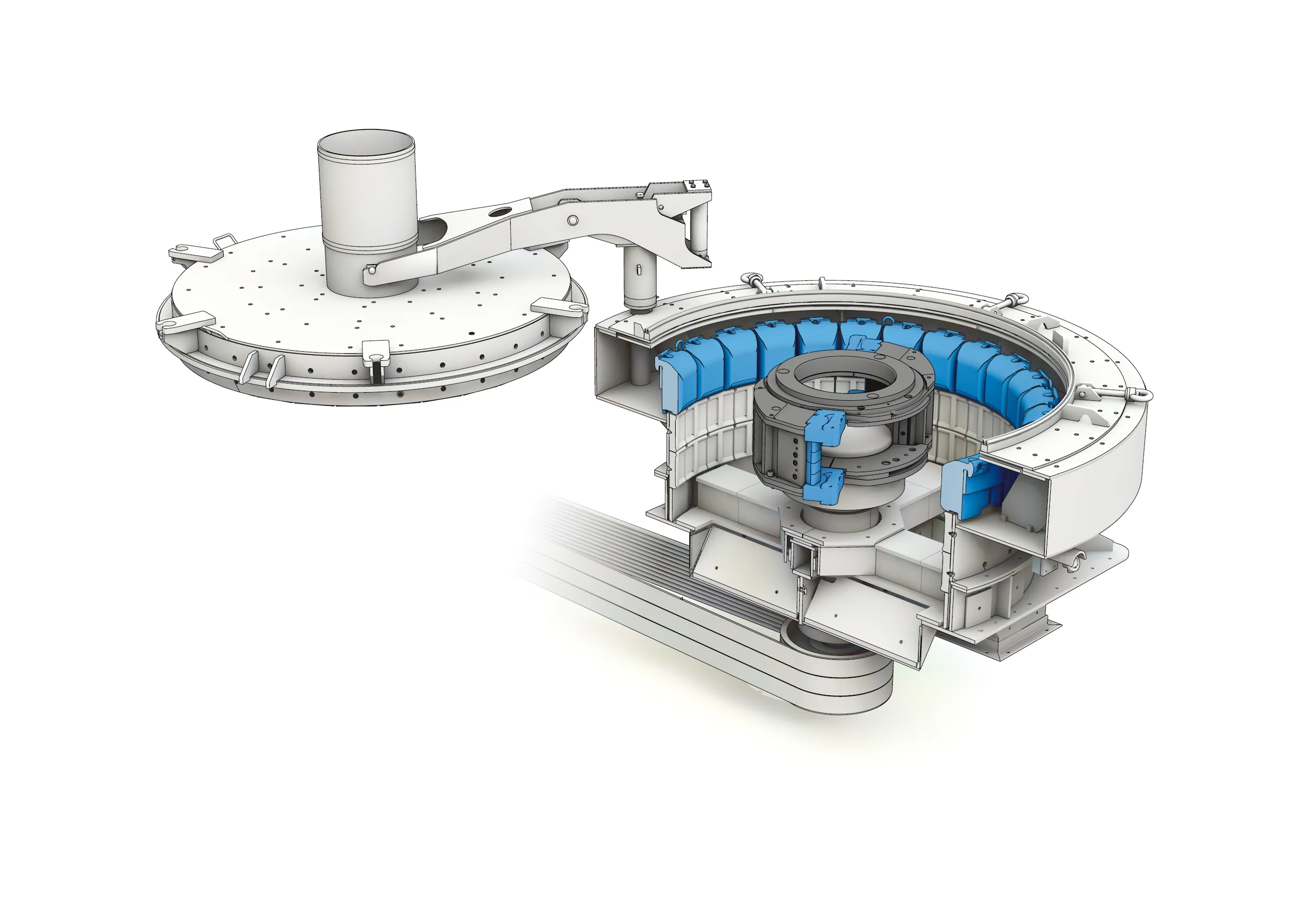

“As is the case for all Keestrack crusher units, the heavy construction of the 1,250mm wide rotor of the R8 and its four impact bars (diameter: 1,267mm, weight approximately 6,100kg) and a specifically larger crushing chamber for high crushing capacities at a very smooth operation and a long service life of the tools,” says the company.

“The standard active double-deck pre-screening with crusher bypass optimises the crushing result and minimises wear and tear.”

The machine an also have a double-deck add-on screening unit and oversize-grain recirculating conveyor.

“The optional equipment permits the production of three final grains via conventional removable screening media. Large-scale screening surfaces (each of which are 4,500 x 1,500 mm) and widely projecting stockpile conveyors help avoid frequently occurring bottlenecks of bolted-on screeners that are too small, leading to markedly declining production rates.

“As one of the few manufacturers in this performance segment, Keestrack is offering the approximately 70tonne R8, with a hinged four-axle dolly for transporting the similarly compact large machine by trailer (transport width, 3–3.2m; length 16.7–17.8m, and height: 3.67m (including dolly: 4m) in the 49.5tonne basic version, with all the add-on options, including an overbelt magnet.”

This also applies to the Keestrack R8 top crusher unit (former Destroyer 1313), that is presented as a highly productive mobile solution in the output range of 450tonnes/hour.

“As is the case for all Keestrack crusher units, the heavy construction of the 1,250mm wide rotor of the R8 and its four impact bars (diameter: 1,267mm, weight approximately 6,100kg) and a specifically larger crushing chamber for high crushing capacities at a very smooth operation and a long service life of the tools,” says the company.

“The standard active double-deck pre-screening with crusher bypass optimises the crushing result and minimises wear and tear.”

The machine an also have a double-deck add-on screening unit and oversize-grain recirculating conveyor.

“The optional equipment permits the production of three final grains via conventional removable screening media. Large-scale screening surfaces (each of which are 4,500 x 1,500 mm) and widely projecting stockpile conveyors help avoid frequently occurring bottlenecks of bolted-on screeners that are too small, leading to markedly declining production rates.

“As one of the few manufacturers in this performance segment, Keestrack is offering the approximately 70tonne R8, with a hinged four-axle dolly for transporting the similarly compact large machine by trailer (transport width, 3–3.2m; length 16.7–17.8m, and height: 3.67m (including dolly: 4m) in the 49.5tonne basic version, with all the add-on options, including an overbelt magnet.”