The Belgian mobile crushing & screening manufacturer’s January-February model orders represent the highest two-month period for orders in Keestrack’s 21-year history.

Speaking at the company’s CONEXPO-CON/AGG 2017 press conference, Michael Brookshaw, Keestrack’s global distributor manager, said Keestrack was forecasting turnover of €100 million in 2017-18 – having posted €85 million turnover in 2016. He estimated that Keestrack is now the sixth biggest-selling mobile crushing and screening brand worldwide.

To capitalise on rising sales, Keestrack is expecting to complete the 8,000m² extension of its biggest manufacturing facility, in Šternberk, Czech Republic. This will take the total site footprint to 13,000m². Continued positive trading will see another extension to the site in 2019-20. Keestrack has two other manufacturing sites – in Pozano, in the Veneto region of Northeast Italy, and in Chuzhou, China.

Brookshaw said Keestrack had expanded its North America sales and distribution team after last year establishing a new North America HQ in Krum, Texas. The manufacturer is looking to tie up new North American distributors during the show.

Headquartered in Bilzen, Belgium, Keestrack - an independent, family-owned firm - directly employs more than 650 staff in its international manufacturing and aftersales activities. The company’s sales and service network today covers more than 50 countries on all continents, totalling nearly 70 dealer and service partners.

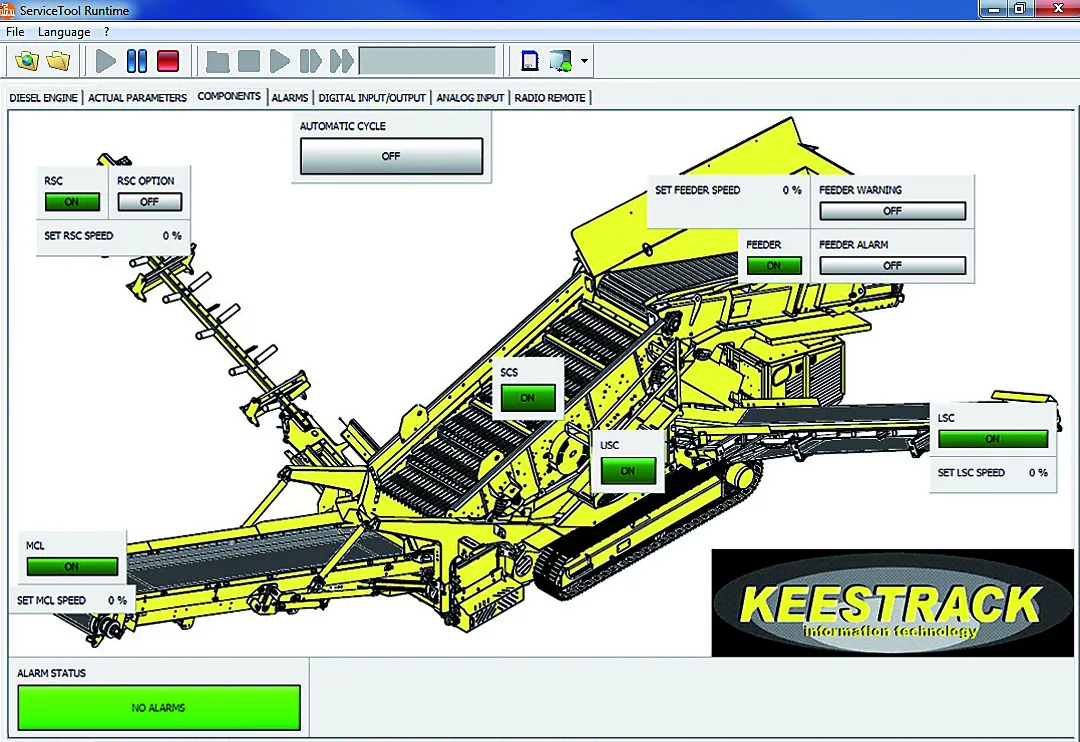

The Keestrack portfolio currently features 25 different models in seven product lines covering all relevant screening and crushing technologies.

A new full-hybrid version of the up to 250tonnes/hour Keestrack H4 cone crusher is on show in Las Vegas. The H4e allows full electric operation through mains or an external gen set. An additional electric motor/hydro pump then supplies the hydraulic driven feeder, the secondary screen module, the tracks and all hydraulic cylinders.

Two further full-hybrid H-series mobile cone crushers – the 350tonnes/hour, secondary crushing-suited H5e and the 350tonnes/hour H6e, ideal for tertiary crushing – are due to be launched in the next 12 months. A third model, the H7e, will also come onto the market in the next 12-18 months. Brookshaw said the full-hybrid H4e model offers huge total cost of ownership savings over a five-year period compared to the standard H4 model.

Keestrack will be unveiling globally a new patented crushing system on new design tracked mobile crushing plants in summer 2017.