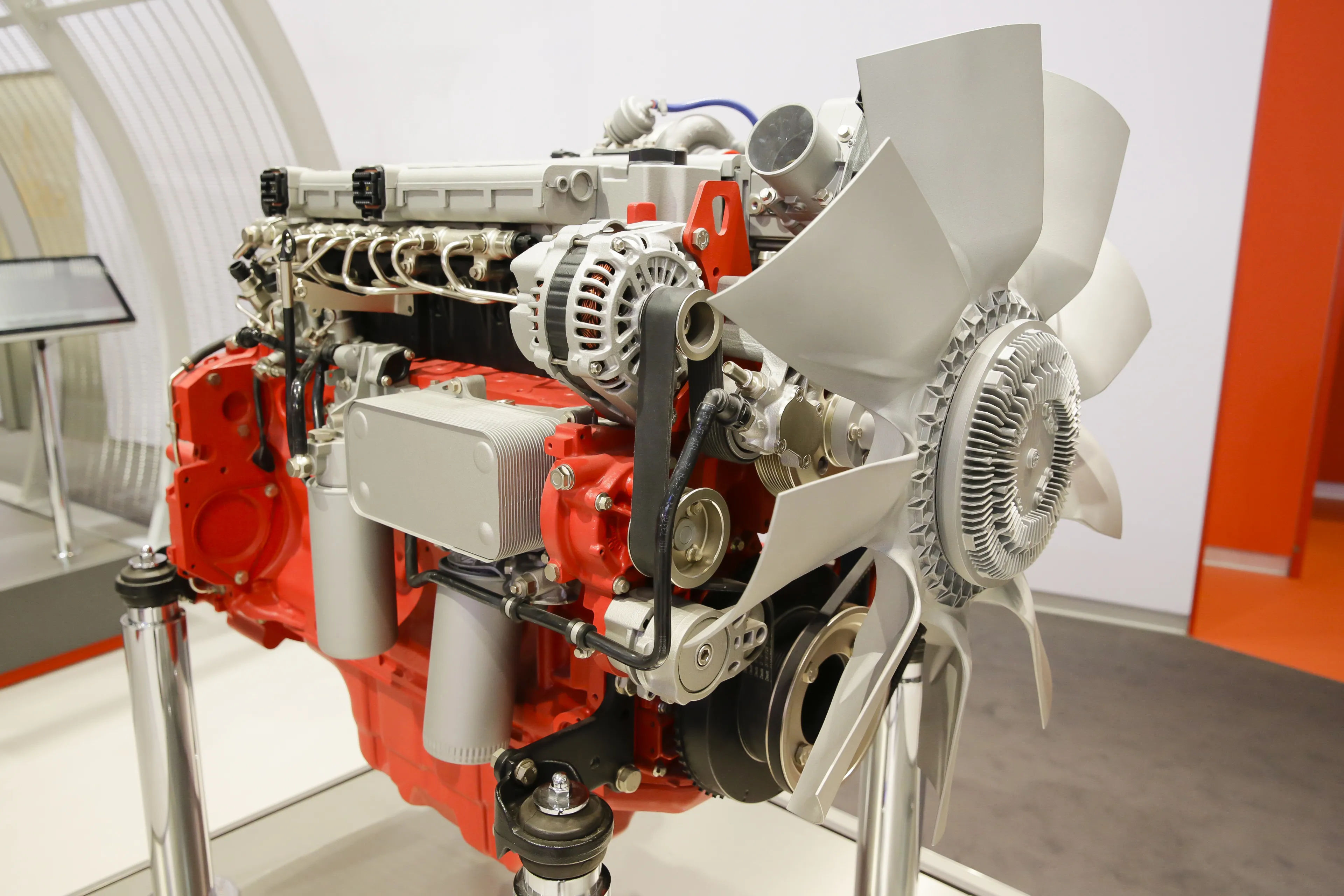

Kohler will be further promoting its new KDI (Kohler Direct Injection) family of diesel engines that has now expanded with the introduction of the new KDI 3404 model.

Produced in the Kohler Engines’ diesel production facility at Reggio Emilia, Italy, following Kohler’s acquisition of Lombardini in 2007, the new KDI 3404 engine is available in two models and four power ratings, and complies with Tier 4 Final, Stage IV regulations within the 56-100 kW power range thanks to the compact, high-efficiency SCR (s

January 6, 2017

Read time: 2 mins

As with the smaller models, the KDI 3404 uses high-pressure common rail fuel injection, four valves per cylinder and solenoid injectors. It also has exhaust gas recirculation (EGR) as part of an emissions package that includes a Diesel Oxidation Catalyst (DOC) and Selective Catalytic Reduction (SCR) in a single exhaust unit, yet does without a Diesel Particulate Filter (DPF).

Kohler CEO Vicenzo Perrone says the engine is also ready for the move to Stage V in 2019, with the addition of a compact DPF within the same one-box exhaust system. The existing all-in-one module can simply be replaced with the new exhaust box, making it easy for equipment manufacturers to make the change to the new emissions regulation.