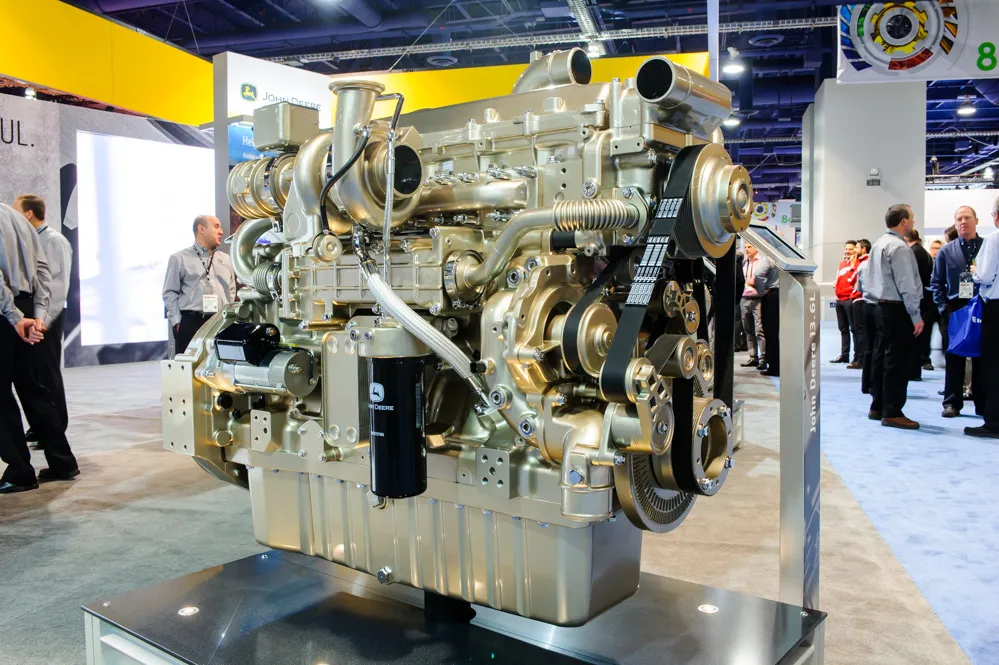

Due to go into production in 2020, the Stage V compliant power unit will replace the current 13.5litre design, delivering more power in a lighter engine and with better packaging.

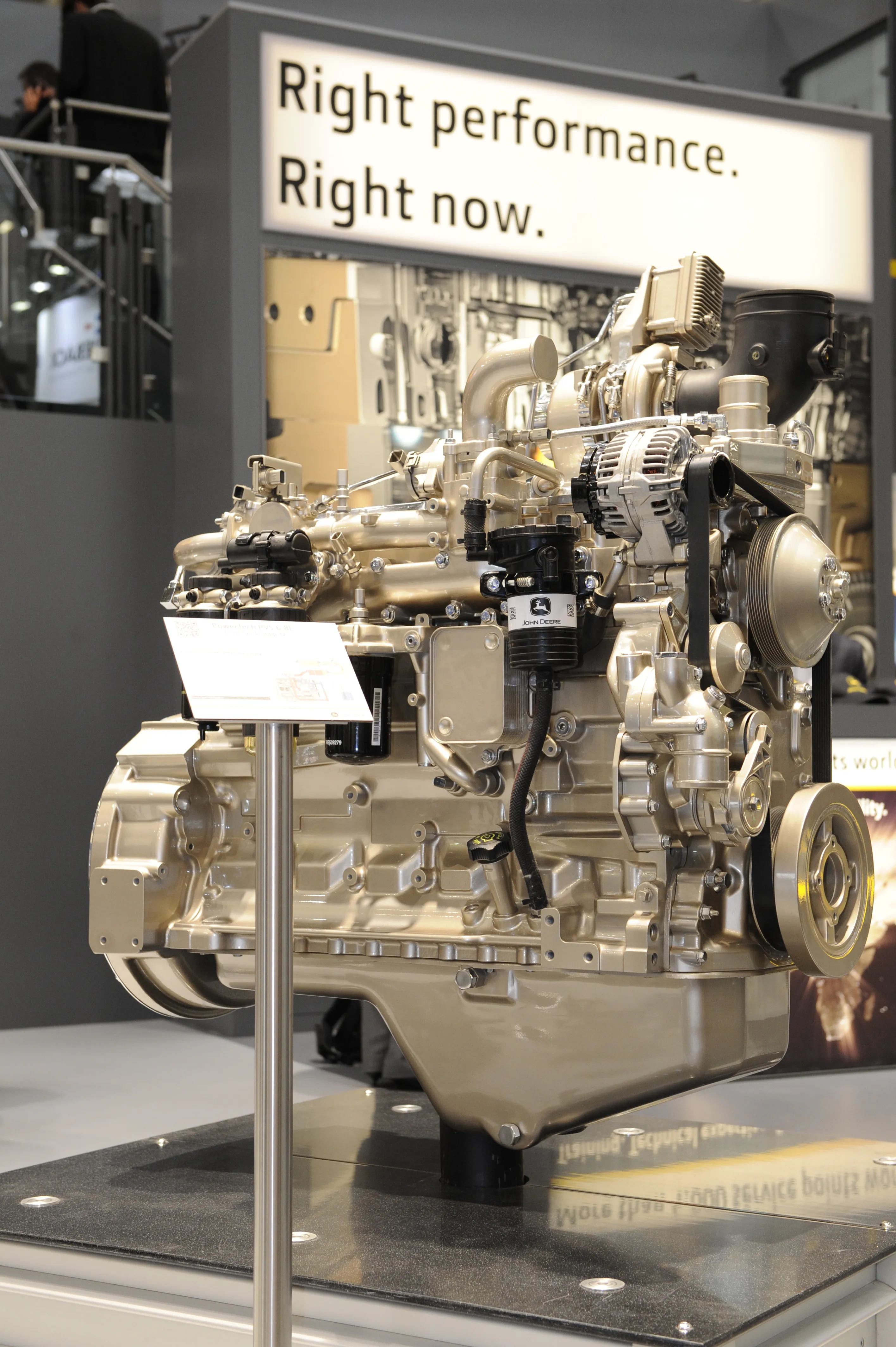

Opting for a clean-sheet design allowed Deere engineers to include and integrate all the latest technology rather than pursuing an add-on format. An example of this is the cooled EGR module, which is bolted to the side of the cylinder block rather than residing on brackets.

Key design changes include the relocation of the engine’s gear train from the front to the back of the engine block. Greater torsional rigidity and quieter running are the results, along with the addition of two full-power PTO drives for ancillaries.

The redesign also affords full power transfer off the nose of the crankshaft, which is not possible with the existing 13.5litre.

Hydraulic lash adjustment is now part of the valve train design and the option to include a compression brake also exists for this new engine. JDPS said customers can expect to see a 20% reduction in maintenance costs, and longer oil drain intervals from the new engine.