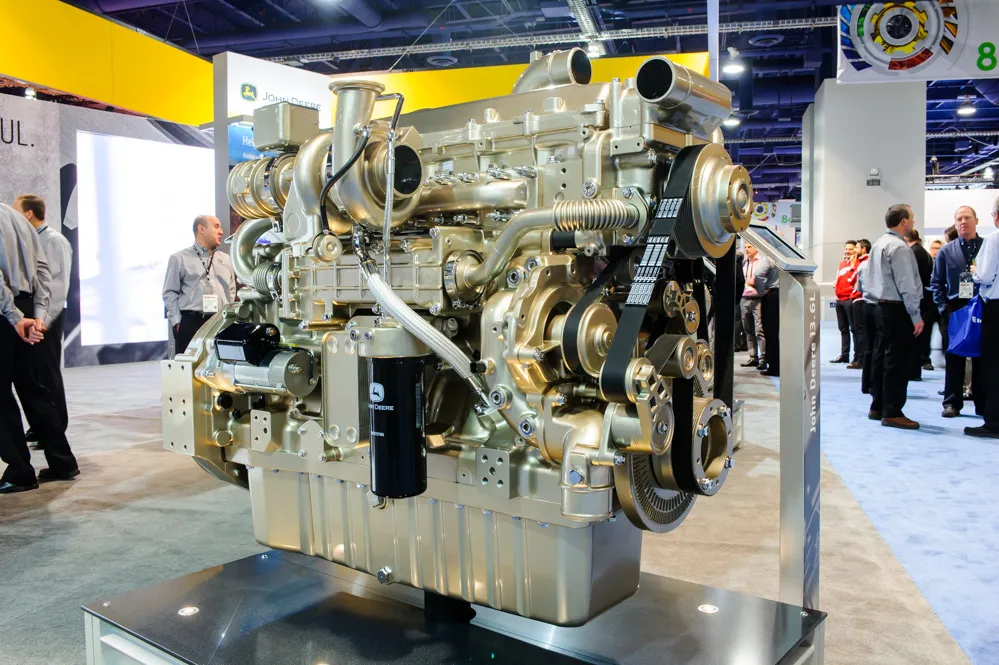

A drivetrain electrification solution from

It announced the move at CONEXPO-CON/AGG, following several years and 300,000hours of in-field testing by customers operating its 644K hybrid wheeled loader. As a result, the firm is confident of the durability and performance offered by its hybrid powertrain solution, and that is backed up by the announcement of a 20,000hour warranty on electrical components on its larger 944k hybrid wheeled loader.

JDPS claims that the hybrid powertrain solution offers better controllability and finer management of power compared to traditional drivelines in wheeled loaders. In the 644K for example, an electric generator/pump drive produces 200kW of power, which is then fed into an inverter. Here, DC current is created and fed into an electric motor, which drives the loader’s powershift transmission.

This power supply process also includes hydraulic functions too, offering full flow capability and greater performance as a result. The hybrid drive has also meant a smaller 6.8litre engine can match the work of a 9litre engine.