JCB has forged a partnership with leading global manufacturer Kohler Global Power Group to produce engines for its compact equipment.

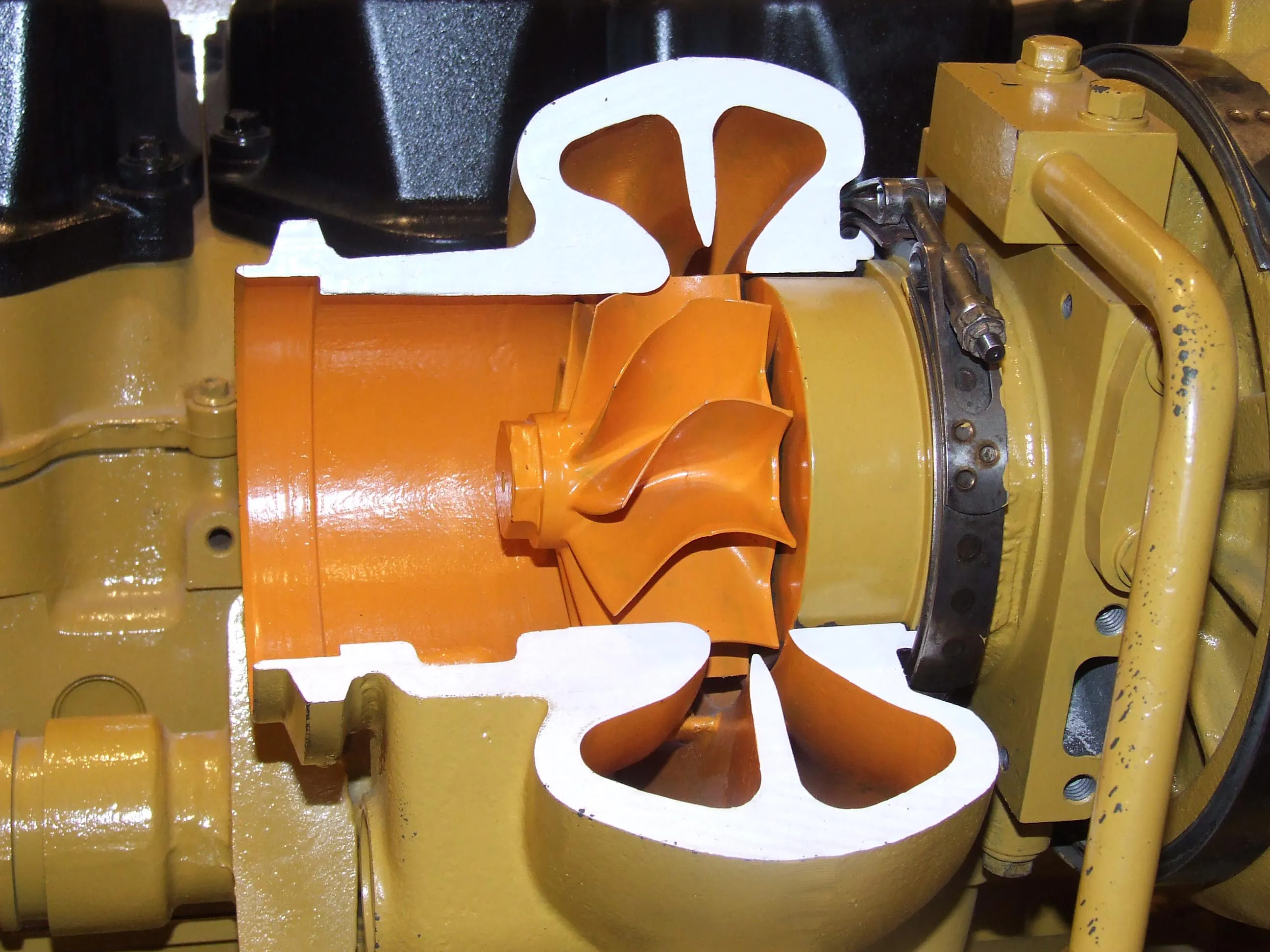

The water-cooled Kohler Direct Injection (KDI) engines - which will be branded JCB Diesel by Kohler - meet the next stage of emissions regulations without the need for a diesel particulate filter (DPF).

The first JCB machine to be fitted with the new engine - a JCB 35D 4x4 Teletruk – was recently unveiled at the RWM waste management show at the NEC in Birmingham, Engla

January 31, 2014

Read time: 2 mins

The water-cooled Kohler Direct Injection (KDI) engines - which will be branded JCB Diesel by Kohler - meet the next stage of emissions regulations without the need for a diesel particulate filter (DPF).

The first JCB machine to be fitted with the new engine - a JCB 35D 4x4 Teletruk – was recently unveiled at the RWM waste management show at the NEC in Birmingham, England. The Teletruk is JCB’s innovative and award-winning telescopic forklift, saving customers time and money with its innovative ability to reach forwards, enabling single side loading and accurate placement of loads.

JCB has gone from a new entrant in engine manufacturing to an innovative global producer with the first JCB engine rolling off the production line in the UK in November 2004. Since then production has been extended to JCB India’s HQ at Ballabgarh and to date more than 250,000 engines have been produced globally.