A leading UK civil engineering firm has hailed the fuel efficiency of JCB’s new tier 4i tracked excavators.

Surrey-based J Devine Group has just purchased three JS130 models and is already impressed by the machines’ fuel efficiency and reliability on its housebuilding projects.

December 3, 2013

Read time: 2 mins

A leading UK civil engineering firm has hailed the fuel efficiency of JCB’s new tier 4i tracked excavators.

Surrey-based J Devine Group has just purchased three JS130 models and is already impressed by the machines’ fuel efficiency and reliability on its housebuilding projects.

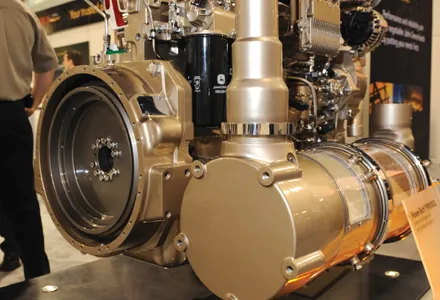

The JS130s are fitted with the T4i-compliant, 68kW255 JCB Ecomax engine, developed as part of the company’s intensive fuel efficiency and emissions reduction drive which has seen worldwide customers save in excess of 750million litres of diesel since 2010.

In addition, the machines - fitted with the JCB LiveLink telematics fleet management system - can be monitored remotely to enable J Devine to fully analyse every aspect of performance.

J Devine plant manager Tim Brackley said, “With diesel prices as they are, fuel efficiency is massively important for us. To date the three machines are averaging between 6.5 & 8.1 litres per hour. If they maintain those rates we will be absolutely delighted. No one is quite sure what the future holds regarding carbon emissions, but the figures on these models are also good and we are pleased to have invested in machines at the forefront in technology to keep us ahead of the game.

“LiveLink is also a huge benefit. It allows us to continually monitor every aspect of the machines performance. With the click of a mouse I can send reports to the board of directors who can assess the latest status and ensure our investment is being maximised.”

JCB claims to be the only leading equipment and engine manufacturer in the world to have met the EU Stage IIIB/US Tier 4 Interim emissions standards by having no after-treatment. It has been achieved through the use of innovative in-cylinder technologies alone, rather than resorting to external exhaust after-treatment or a diesel particulate filter (DPF).

The three T4i machines have been working on a series of housebuilding projects including a new development at Queen Elizabeth Barracks, Church Crookham, Hampshire where one of the JS130 models has been joined by an 18tonne JCB JS160 on trial following the successful introduction of JCBs into the J Devine fleet.

Surrey-based J Devine Group has just purchased three JS130 models and is already impressed by the machines’ fuel efficiency and reliability on its housebuilding projects.

The JS130s are fitted with the T4i-compliant, 68kW

In addition, the machines - fitted with the JCB LiveLink telematics fleet management system - can be monitored remotely to enable J Devine to fully analyse every aspect of performance.

J Devine plant manager Tim Brackley said, “With diesel prices as they are, fuel efficiency is massively important for us. To date the three machines are averaging between 6.5 & 8.1 litres per hour. If they maintain those rates we will be absolutely delighted. No one is quite sure what the future holds regarding carbon emissions, but the figures on these models are also good and we are pleased to have invested in machines at the forefront in technology to keep us ahead of the game.

“LiveLink is also a huge benefit. It allows us to continually monitor every aspect of the machines performance. With the click of a mouse I can send reports to the board of directors who can assess the latest status and ensure our investment is being maximised.”

JCB claims to be the only leading equipment and engine manufacturer in the world to have met the EU Stage IIIB/US Tier 4 Interim emissions standards by having no after-treatment. It has been achieved through the use of innovative in-cylinder technologies alone, rather than resorting to external exhaust after-treatment or a diesel particulate filter (DPF).

The three T4i machines have been working on a series of housebuilding projects including a new development at Queen Elizabeth Barracks, Church Crookham, Hampshire where one of the JS130 models has been joined by an 18tonne JCB JS160 on trial following the successful introduction of JCBs into the J Devine fleet.