JCB has started full production of its new Hydradig after the machine made its international debut at the equipment trade fair bauma in Munich in April.

JCB says it has already received hundreds of orders for the new 10tonne machine which is being manufactured at the JCB Heavy Products plant in Uttoxeter, Staffordshire, England. Around 85 people have been recruited for the production process, including engineers, welders and assembly line employees.

The JCB Hydradig was developed in complete secrecy o

July 7, 2016

Read time: 2 mins

JCB says it has already received hundreds of orders for the new 10tonne machine which is being manufactured at the JCB Heavy Products plant in Uttoxeter, Staffordshire, England. Around 85 people have been recruited for the production process, including engineers, welders and assembly line employees.

The JCB Hydradig was developed in complete secrecy over three years under the codename Project 710. A statement from JCB said the vision was to design “the most innovative solution in response to five key challenges facing customers in today’s construction sector - visibility, stability, manoeuvrability, mobility and serviceability”.

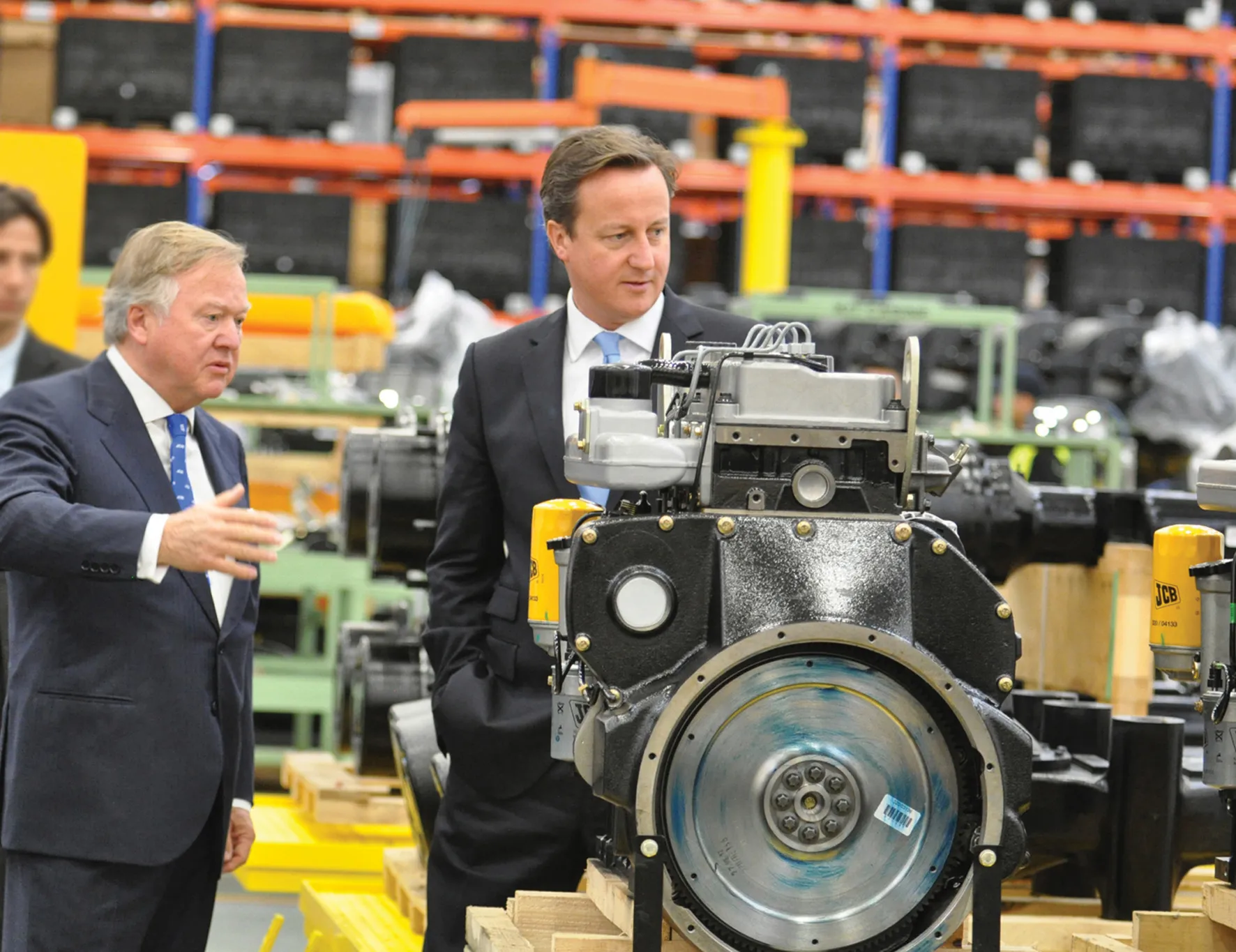

JCB chairman Lord Bamford, who initiated the project, said: the Hydradig “will transform the industry”.

JCB chief executive Graeme Macdonald said the Hydradig is the third product revolution the company has brought to market in the past six months. “We’ve launched a backhoe loader which is 35% smaller than the standard model which is opening up new sales opportunities around the world. For our farming customers, we have just introduced a brand new dual-technology transmission for JCB’s Loadall telehandler products which makes them 25% more productive than competitive models.”

Chief innovation and growth officer Tim Burnhope said that JCB worked with customers to conduct in-depth analysis of the potential applications for the Hydradig, including utilities, highways, municipalities, general construction and landscaping, as well as to assess the suitability of current machinery solutions. With job sites becoming increasingly congested, whether in an urban environment or on busy road carriageways, it became clear that a rethink of machine design was needed.

“Visibility from the cab was the main customer consideration because of on-site safety concerns,” said Burnhope. “Stability was next on the list, as machines are now being called upon to do an increasing amount of heavy lifting, not just excavating. As job sites become tighter many customers are demanding improved manoeuvrability, while others need increased mobility to allow machines to move between sites more quickly.”