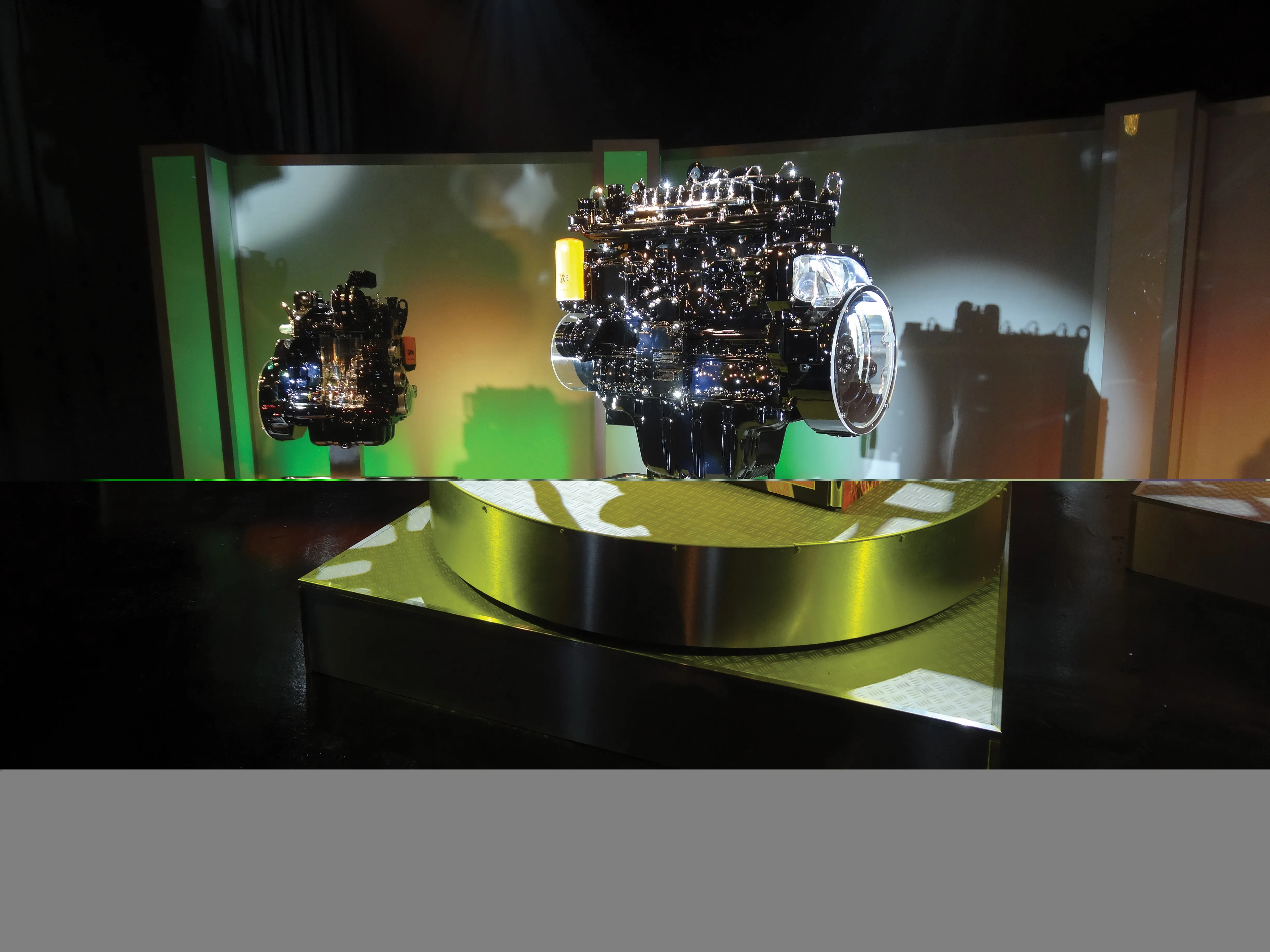

The new engine joins the 4.4, 4.8 and 7.2litre power units, and comprises third generation common rail fuel injection, a rigid-design cast iron engine block, four-valve cylinder head and a deep sump allowing 45degree gradeability.

Compared to the British maker’s 4.4 litre EcoMax engine, the 430 DieselMax boasts fuel consumption up to 8% less, in an engine that is also 30% lighter.

Launched initially with an output of 55kW at Stage IIIB/Tier 4 Final, the 3.0litre engine produces 400Nm of torque at 1300rpm. JCB said the engine also meets relevant emissions legislation without any requirement for a DPF, SCR or any form of exhaust additive or after-treatment.

In addition, JCB reports that the engine has been designed to be ready for Stage V emissions standards and additional power ratings in the future.