A new remanufactured truck service from

“This isn’t putting lipstick on a pig,” said Tim Frank, president of IronDirect. “It’s complete remanufacturing. You basically create something new.”

The goal in truck remanufacturing is to save 50% off the cost of a comparably-equipped new vehicle. The implications are particularly significant for fleet owners, Frank said. Large businesses can own thousands of trucks, and the savings could be in the millions.

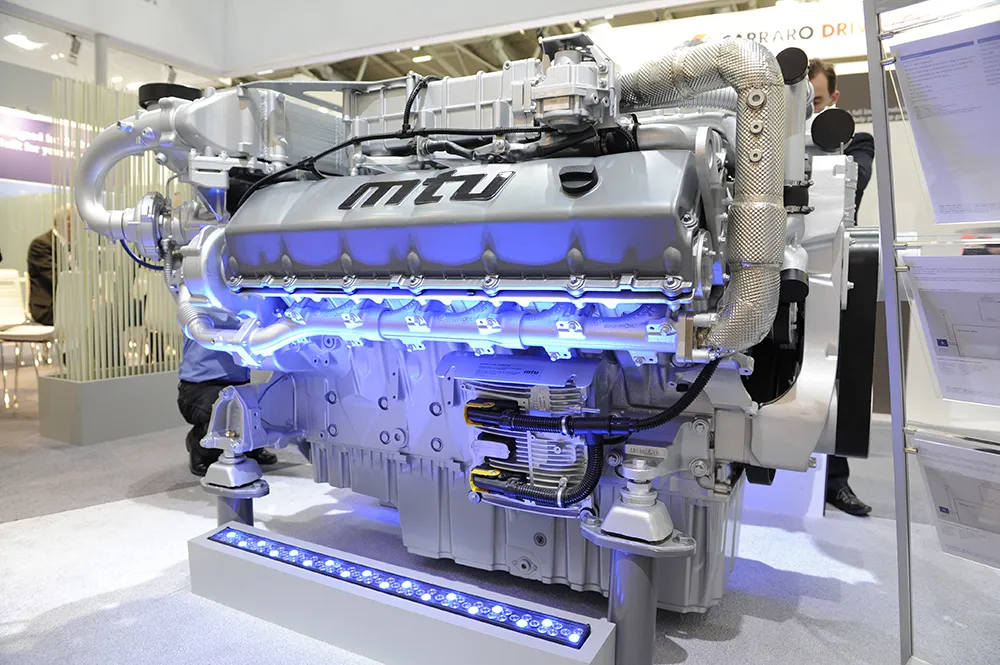

While vehicle components and systems such as engines and transmissions have been remanufactured for years, no one had yet established a standardized assembly-line system to remanufacture trucks and other vehicles to like-new condition, Frank said. IronDirect Reman Trucks have a three-year 75,000-mile drivetrain warranty that attests to the quality, he said.

The IronDirect Reman Trucks system focuses on class 1 to 5 trucks (19,500 pounds and lighter). A Ford F-350 on display at ConExpo is typical of the dozen-step remanufacturing process. In the initial steps, all fuel and fluids were extracted from the vehicle before teardown began. The cab and bed were separated from the frame. The engine, transmission, and drivetrain were removed and later replaced with reman systems. The frame was inspected.

The body was patched and sanded before painting. Interior upholstery was replaced. New glass was installed where needed. New tyres were balanced and installed.

“We’re excited to help bring truck reman to a wide market,” Frank said. “Truck reman will be one of the memorable business trends of 2017 and beyond.”