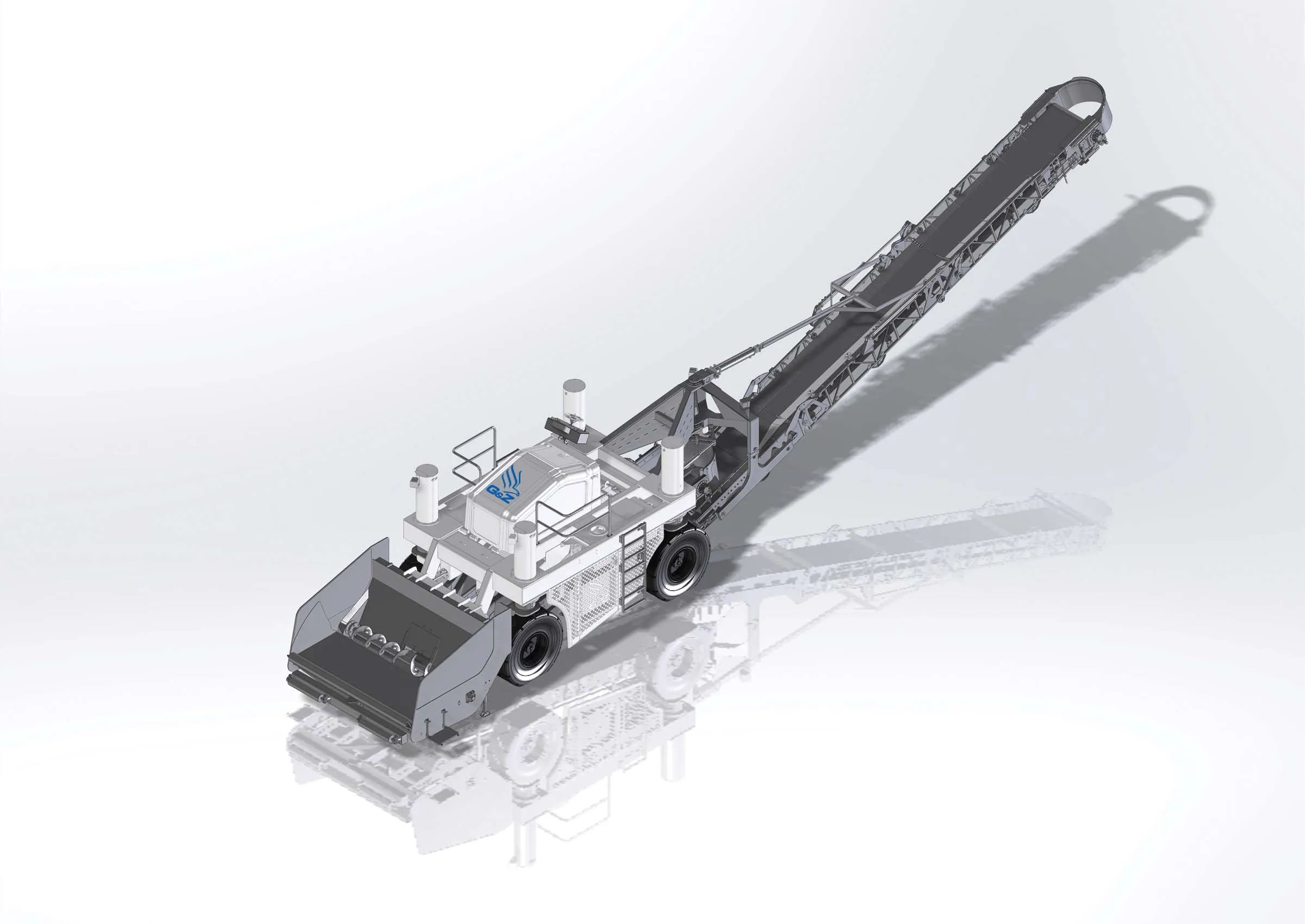

IROCK Crushers says it designed the new TJC-3046 with easy operation, durability and efficiency in mind.

For example, a user-friendly electronic crusher control system with touch-screen display is easy to operate and simplifies crushing, service and maintenance, said the company. The high performance primary jaw crushing plant is designed for medium-scale operators in quarrying, demolition, recycling and mining applications.

March 11, 2014

Read time: 2 mins

For example, a user-friendly electronic crusher control system with touch-screen display is easy to operate and simplifies crushing, service and maintenance, said the company.

The high performance primary jaw crushing plant is designed for medium-scale operators in quarrying, demolition, recycling and mining applications.

The TJ-3046 features a 10m³ feeder and includes a grizzly pre-screening grid. The feeder drive features a load control system to ensure continuous, uninterrupted crushing. An optional level sensor can be fitted to the jaw and control the feed rate to the crusher, therefore maximising production, said IROCK.

The jaw crusher has an inlet opening of 1.4m x 91.4cm and is equipped with a hydraulic wedge adjustment to give operators Total control of product size down to 5cm.

“TJ-3046’s high swing jaw generates an aggressive crushing action and accelerates movement of material into the crushing chamber. The crusher discharge conveyor can stockpile up to 11feet 6inches [4.2m],” said IROCK. A dirt conveyor is standard on the machine.

“The TJ-3046 can be equipped with a wireless remote control and features track mobility for relocation around a job site or onto a heavy-haul trailer and its hydraulic folding sides make for easier set-up and tear down.”

Powered by a Caterpillar C-9 ACERT Tier 3 engine, the TJ-3046 can produce up to 445tons/hour (404tonnes).

www.irockcrushers.com