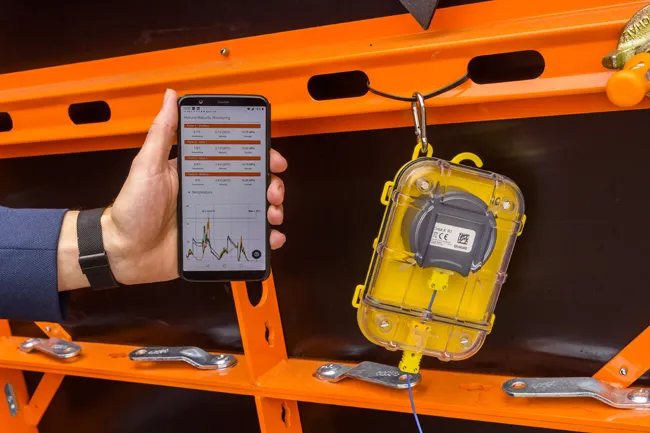

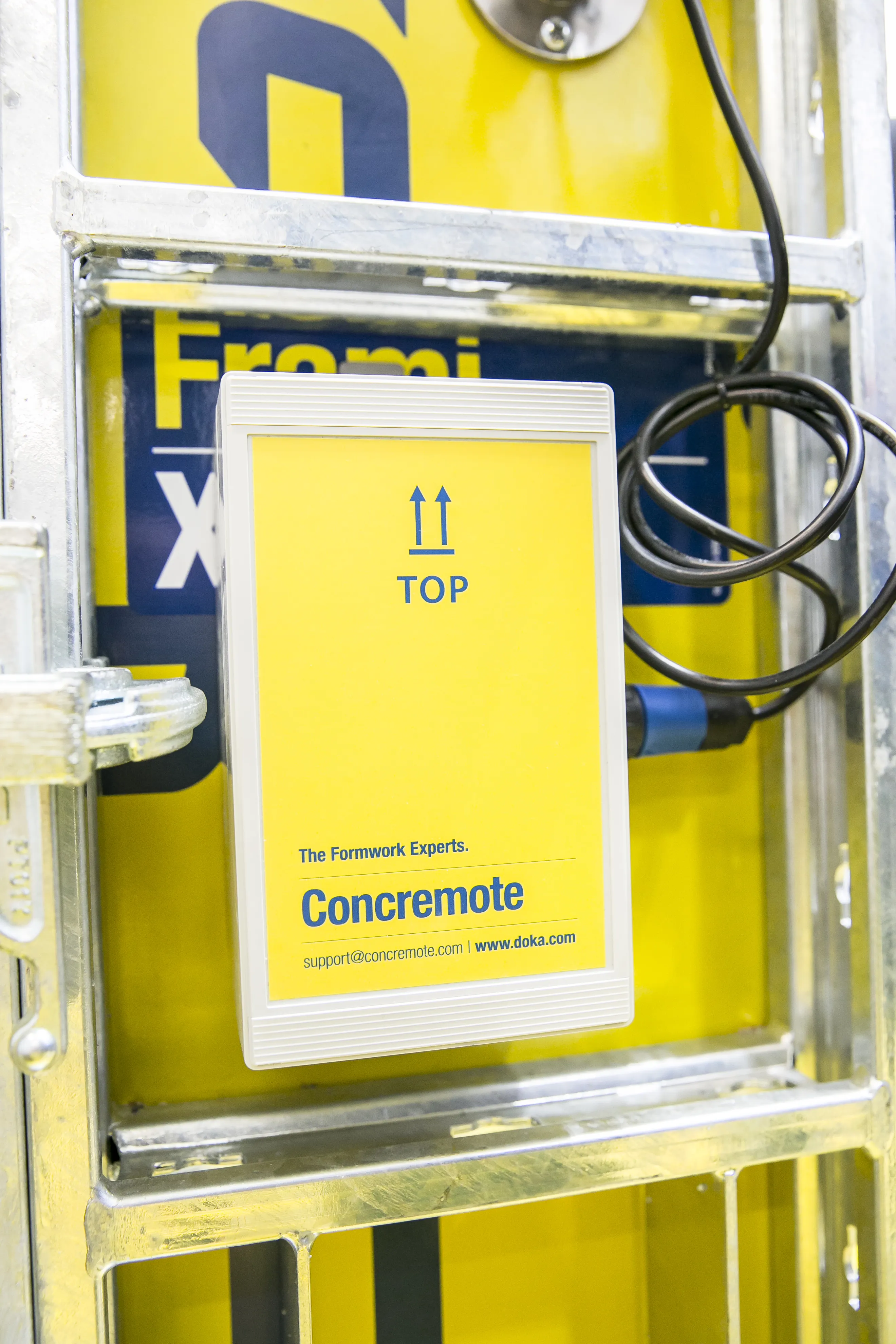

Intelligent monitoring of concrete strengths is helping contractors shave weeks off construction programmes, according to formwork specialist

“Concretemote is being used on 20 to 25 projects,” said Doka’s director of research and development Johann Peneder. “In some countries we cannot fully use the advantages of Concremote due to the regulations, which are based on previous experience, but this is the first steps towards employing techniques which will give a more efficient and economical way to build.”

The latest development of the Concremote system will see formwork panels with ready-made positions for the Concremote sensor to plug into - currently it sits on top of the concrete pour. Called Concremote plug.IN, this addition will allow faster and more flexible monitoring of concrete strengths, Peneder added.

“Contractors can use products such as Concemote for long-term quality monitoring of the job sit,” he continued. “They can then add that data into the BIM model and can transfer that data to the owner.”

One of Concremote’s current applications demonstrates its benefits in countries with huge climatic variation. On Canada’s Muskrat Falls hydro power project, where temperatures can fall to minus 40degrees C, it has allowed earlier striking of forms but also ongoing monitoring of the concrete after striking. This allows the contractor to protect the concrete where necessary to avoid temperature shock - between the hot concrete and cold outside - and hence prevent damage.