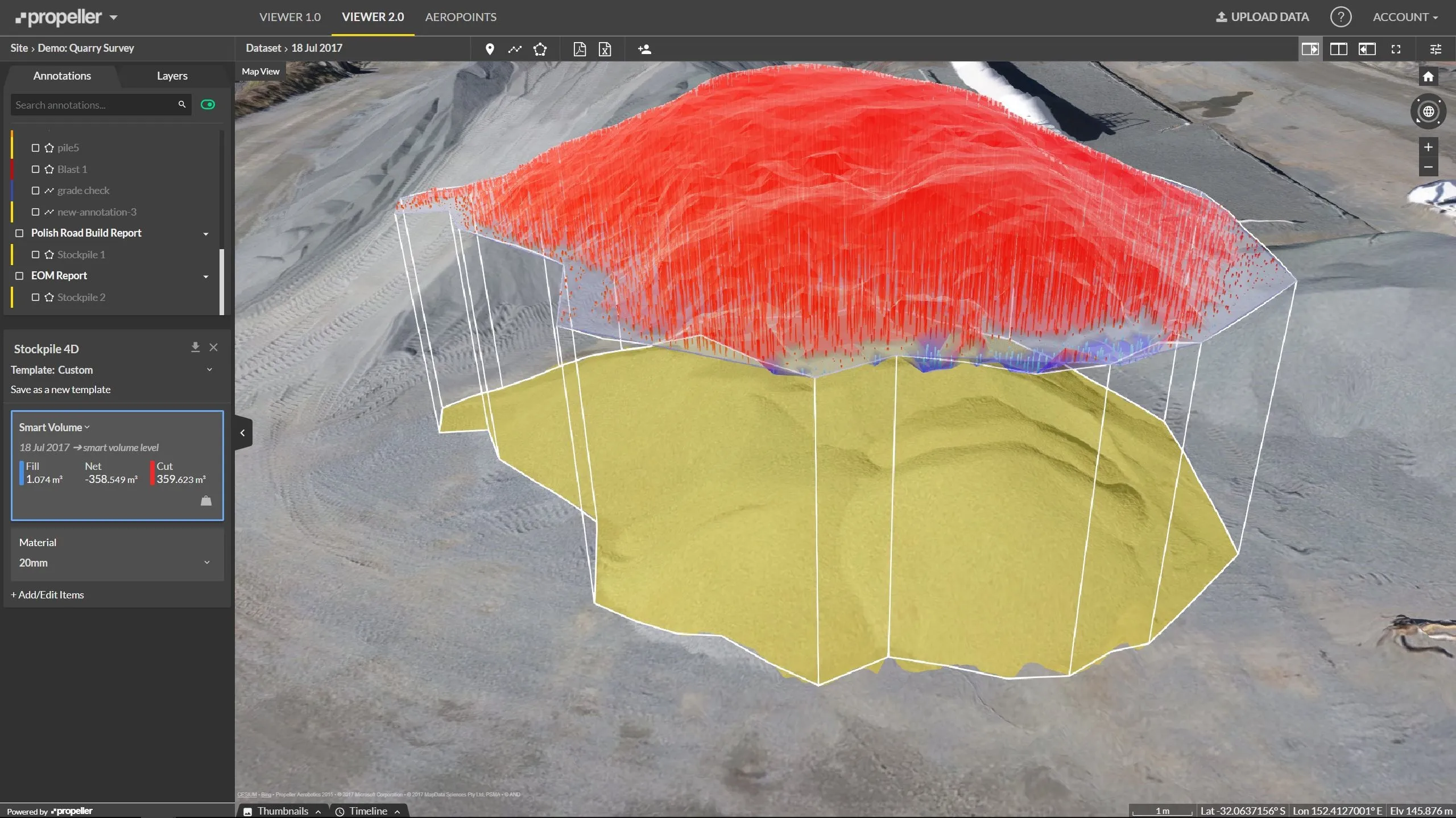

InEight Project Suite will accept models from any design package and includes modules for estimation, contract management, planning, budget control and inspection. It enables all elements of a project – and the people involved – to be connected in an integrated environment.

Previously, the Project Suite would run only on on-premises computers. Now it will run in the cloud as well, giving access for all users anytime, anywhere.

InEight Project Suite in the cloud is another step by the industry towards a complete and integrated virtual model of an entire construction project - including all associated data that is immediately accessible to architects, engineers, foremen, project managers and other stakeholders.

“The InEight Project Suite connects people and projects through real-time sharing of information to drive project performance,” says Mike Paul, InEight's global channel director. “We can pull in data from all the relevant sources and integrate it for estimation, scheduling and all parts of the project process. Project Suite in the cloud expands the potential of our market.”

The cloud version of Project Suite is currently in beta testing with construction company Kiewit, which owns InEight. The software will be officially released in May.