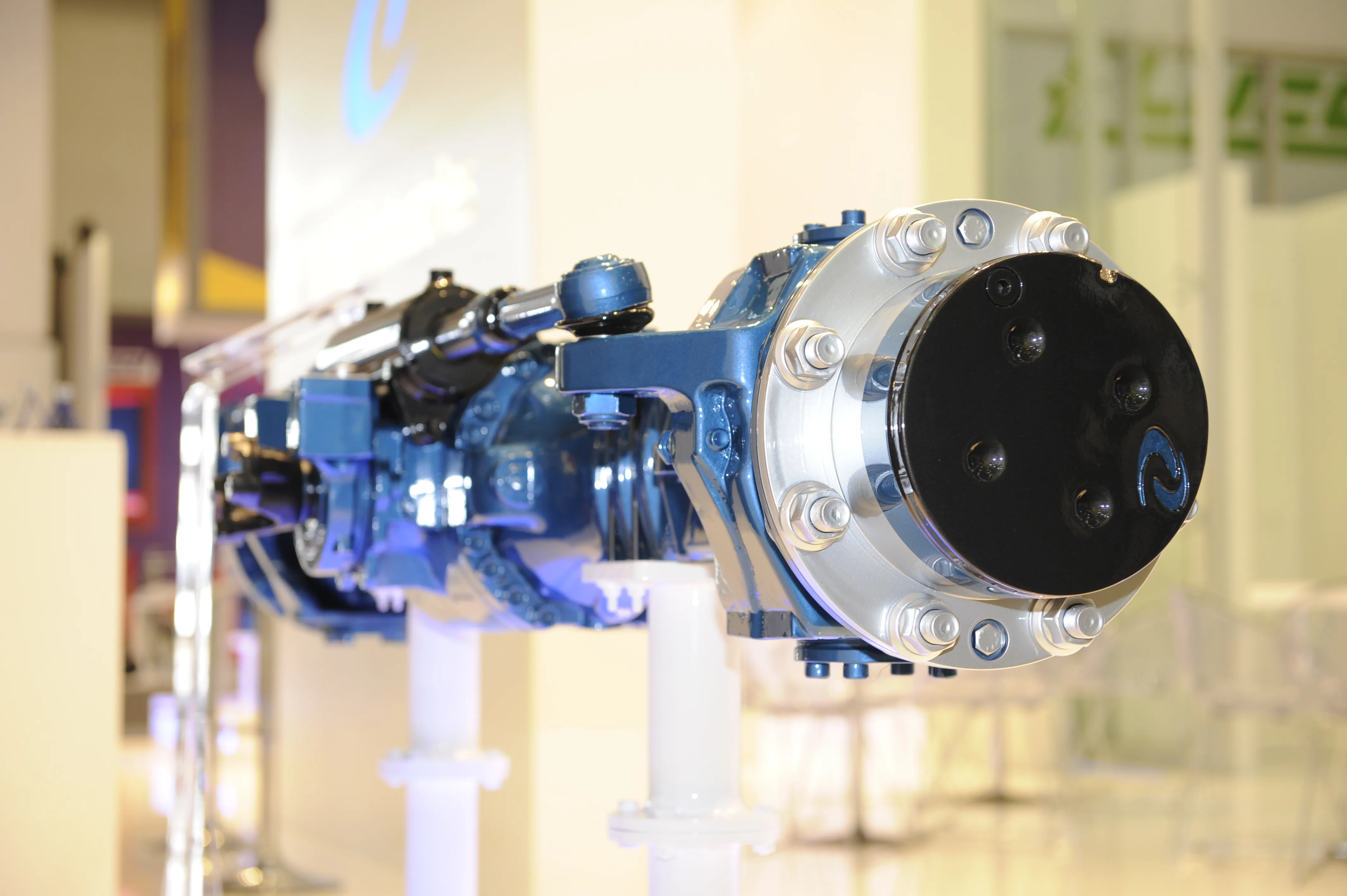

Indeco has totally redesigned its ISS steel shears. On show at the bauma stand was the ISS 30/50; the manufacturer aims to introduce the new features to the entire range in the future.

“Our customers were asking us whether we could increase the speed of the steel shear, increase the clamping force and reduce the wear,” said Indeco technical specialist Alessandro Ciccolella. “We improved the cyclinder’s hydraulic line to give much more speed and we used a new, special material for the blade to increase th

April 19, 2016

Read time: 1 min

“Our customers were asking us whether we could increase the speed of the steel shear, increase the clamping force and reduce the wear,” said Indeco technical specialist Alessandro Ciccolella. “We improved the cyclinder’s hydraulic line to give much more speed and we used a new, special material for the blade to increase the life of the blade.”

The new shears also look different: they are shorter in length, but achieve a wider jaw opening.

All videos