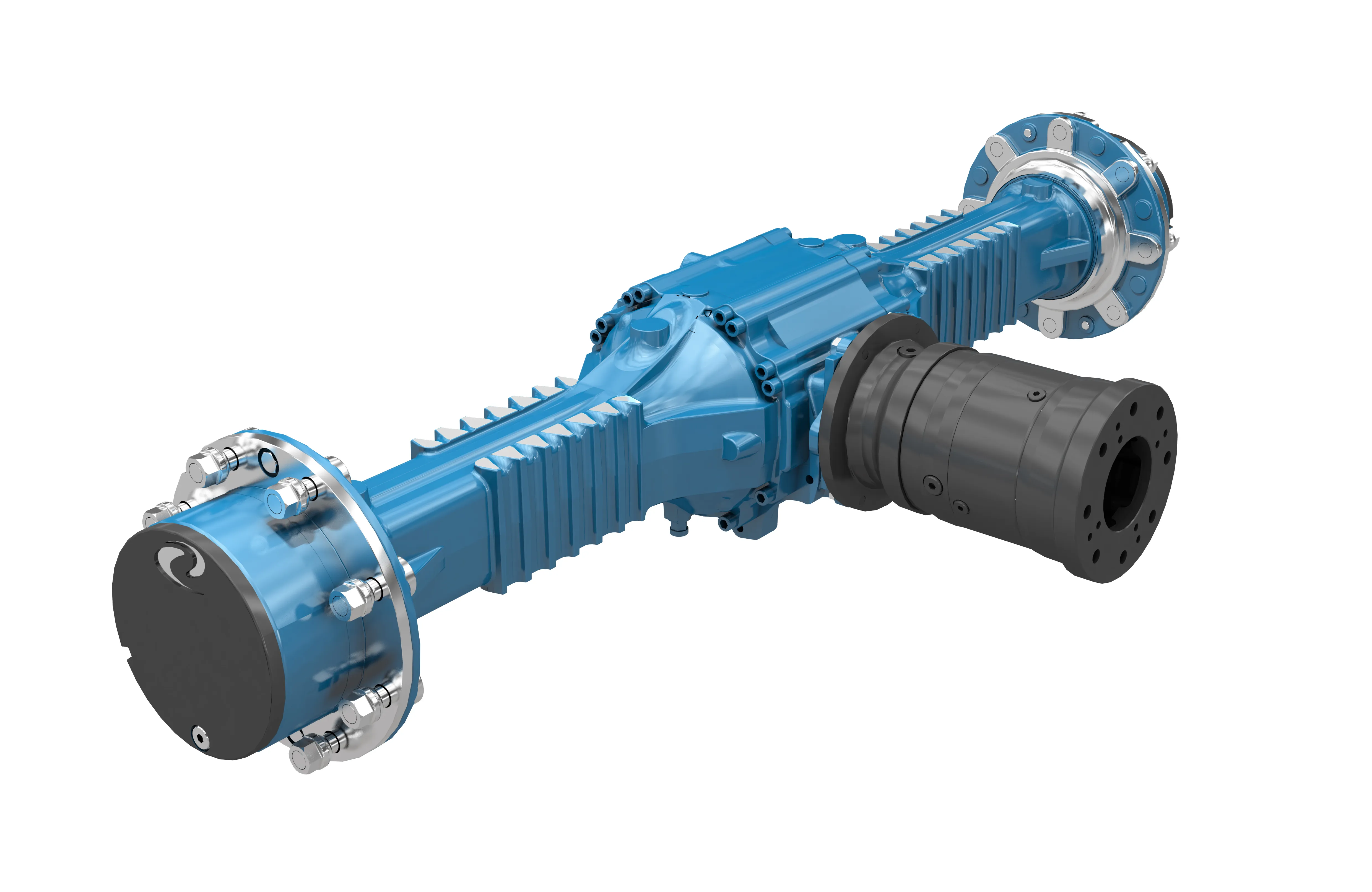

Comer Industries is developing its integrated power transmissions solutions to boost productivity and efficiency for OEMs. The company is adding the S-46 Hydro axle to its line-up for compact wheeled loaders. The axle now benefits from a hydrostatic radial motor mounted in line with the input shaft, permitting four-wheel drive connection with reduced installation space.

Comer is also launching a complete driveline system for soil compactors, the first one being installed on a machine from Atlas Weyhausen

January 6, 2017

Read time: 1 min

Comer is also launching a complete driveline system for soil compactors, the first one being installed on a machine from

Also new to the line-up is a PGR-3600 rotating housing drive. Available for both wheeled and tracked machines, the PGR-3600 series offers higher torque outputs and load capacities than previous models, with Comer claiming increased reliability.