Italian firm Massenza has carried out an extensive redesign of its PMB plant line-up. The new generation of PMB plants from the firm includes three models, the compact Smart model, the medium sized Klever and the top-of-the-range Super Klever.

The Smart model is designed for customers that need lower quantities of PMBs and want to make a relatively modest investment. Increased output is produced by the medium Klever unit while the Super KLEKleverVER offers the biggest output as well as a range of intelligent features. The firm says that its three-model range meets the demands of all road contractors and most of resellers and/or oil companies.

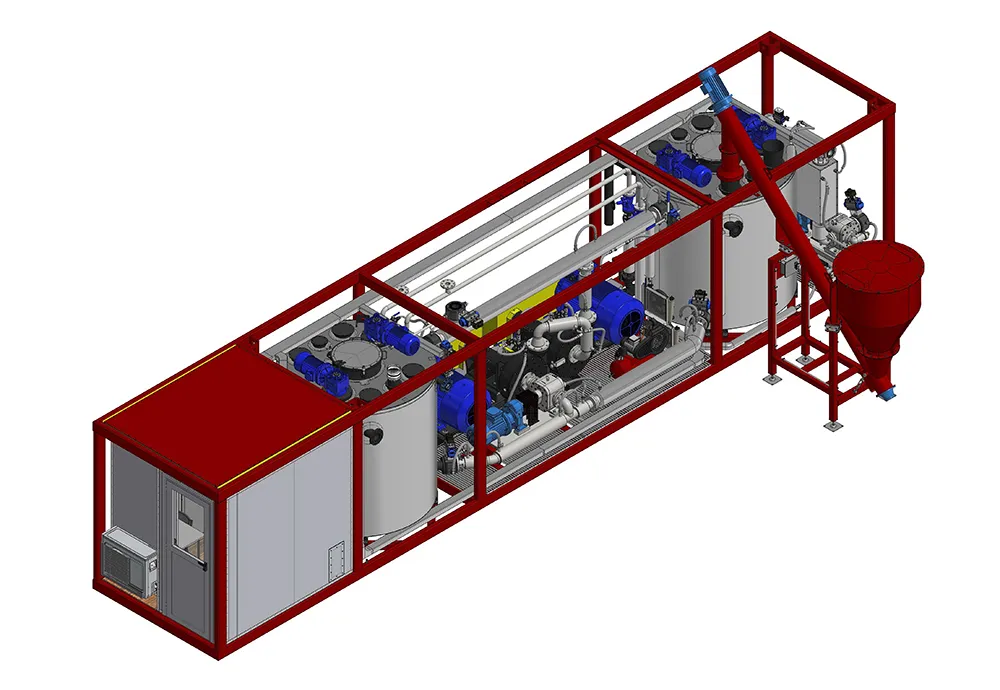

An array of improvements and modifications have been carried out, boosting performance over the previous models. A key feature is that the mixers have now a circular section, reducing the risk of bitumen/polymer residues on the mixer walls and increasing polymer dispersion. The mixers have an automatic heating system that provides better temperature control, preventing overheating and saving energy. High shear mills are placed in the central part of the plant, allowing a more compact design and easier maintenance. In addition, the Klever model can also be upgraded to a Super without any modification to plant’s skid once the plant is at site already. A bigger motor is fitted for the mill feed pump, which boosts performance and means that there is more power for production of materials with high polymer percentages. The new control room is equipped with thermal and acoustic insulation as well as a heat pump for heating/cooling, which provides more comfort for the plant operator. The plants also have reduced dimensions, allowing them to be shipped in a standard container.

All plants can be equipped with a number option, such as polymer big-bags emptying system, various liquid additives dosing and loading systems and a solid additive micro-batch screw feeder.

The first plants of this new generation have already been supplied and commissioned in Saudi Arabia and Romania. Other units are under construction for clients located in Middle East, Europe and South America.