The firm was able to deliver high-speed working while ensuring the asphalt paving work was carried out to optimum standards with the use of a Dynapac MF2500CS mobile feeder.

Cobleskill Stone Products is an aggregate producer, material supplier and construction services provider for upstate New York. The firm carries out a large number of asphalt paving jobs in the state and recently used the Dynapac MF2500CS mobile feeder to help pave two rehabilitated stretches of I-88. One of the sections was located near to Schenevus and the other close to Central Bridge.

“The Central Bridge project included three lifts of blacktop to put down T&L, a binder course and a top course,” explained Michael Moore, vice president of Cobleskill Stone Products.

“The job specs only required using a material transfer vehicle (MTV) for the binder and top course, but we chose to use one for all three courses,” added Dan Mark, the project superintendent on the Central Bridge project. “Using an MTV like the Dynapac MF2500 provides better rideability because there are no truck transitions, and we’re able to lay more tonnage at a constant speed.”

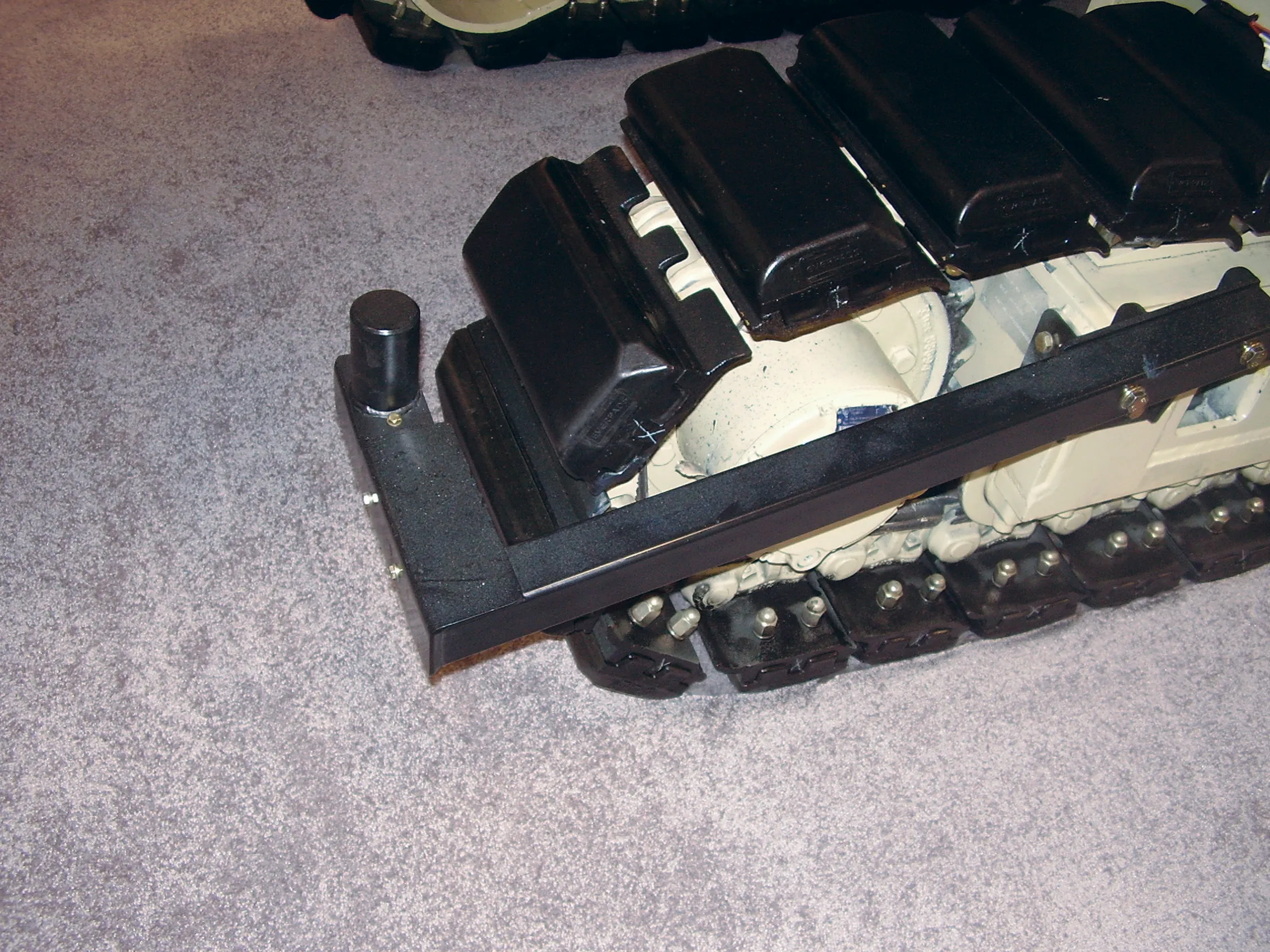

“We looked at multiple brands before choosing the Dynapac MF2500,” said Moore. “Using a tracked machine opposed to a wheeled machine had specific appeal because we were working with crack and seal material. Once we established the carrying capacity met the job specs, we looked at the remix capabilities built into the machine and the oscillating conveyor, and it was clear the machine fit the bill for how we wanted to approach the project.”

At the I-88 Schenevus project, Cobleskill Stone Products’ operators typically laid 5.2m of asphalt/minute, which allowed them to complete echelon paving with two pavers running side-by-side for a portion of the project.

Cobleskill Stone Products was supplied the machine by Anderson Equipment Company for the I-88 project.