Hydro International’s innovative First Defense vortex separator is now available for the first time in the UK, in response to the growing need for economical surface water treatment on highways, car parks and new developments.

Already well-established and proven in the U.S., First Defense uses a gentle vortex action to remove coarse particles, litter and oil from surface water runoff – a requirement which will become increasingly important due to growing regulation for Sustainable Drainage Systems (SuDS).

February 20, 2014

Read time: 2 mins

Already well-established and proven in the U.S., First Defense uses a gentle vortex action to remove coarse particles, litter and oil from surface water runoff – a requirement which will become increasingly important due to growing regulation for Sustainable Drainage Systems (SuDS).

The First Defense has been launched as part of the Hydro StormTrain Series of surface water treatment devices, a comprehensive toolbox for silt, sediment and pollutant removal as part of SuDS.

Designed and developed by HYDRO International (HI), First Defense is already said by HI to be proven in the U.S. and has passed the stringent certification criteria of many U.S. regulatory authorities.

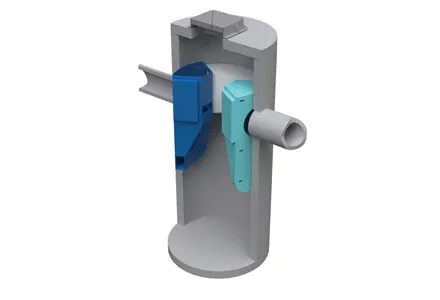

Delivered as a pre-cast standard-size concrete manhole with internal components pre-fitted, First Defense delivers repeatable, predictable, at-source pollution control for small-to medium-size catchments with easy installation and minimal maintenance.

The internal components of the First Defense are designed to create a low energy rotational flow within the chamber, allowing sediments to settle to the sump, while oils, floating litter and debris rise to the upper containment area. Harmful pollutants are therefore captured safely within the device, protecting public areas.

The gentle action of low-energy vortex separation eliminates excessive agitation of captured pollutants, ensuring they are not resuspended during peak flows. During peak rainfall events, the integral bypass also ensures pollutants remain within the chamber and are not washed out.

The orientation of the outlet can be adapted to suit site conditions. Single and multiple inlet pipes are also available, along with an inlet surface grate for maximum design flexibility.

The expectations of the EU Water Framework Directive (WFD) are influencing the development of legislation in England, Wales and Northern Ireland, as well as driving the implementation of established regulations in Scotland. In each case, the Hydro StormTrain Series is said to offer future-proof SuDS-compliance.