Versatile and powerful, the new ZW220-6 and ZW310-6 wheeled loaders from Hitachi offer greater output than before. The machines can be used for a wide range of applications and offer greater reliability than the firm’s earlier generation models. The new Tier 4 Final/Stage IV-compliant engines do not require diesel particulate filters, lowering both maintenance costs and fuel consumption. The firm says that the ZW220-6 for example uses 7% less fuel in load and carry operations and 6% less fuel for loading th

March 4, 2016

Read time: 2 mins

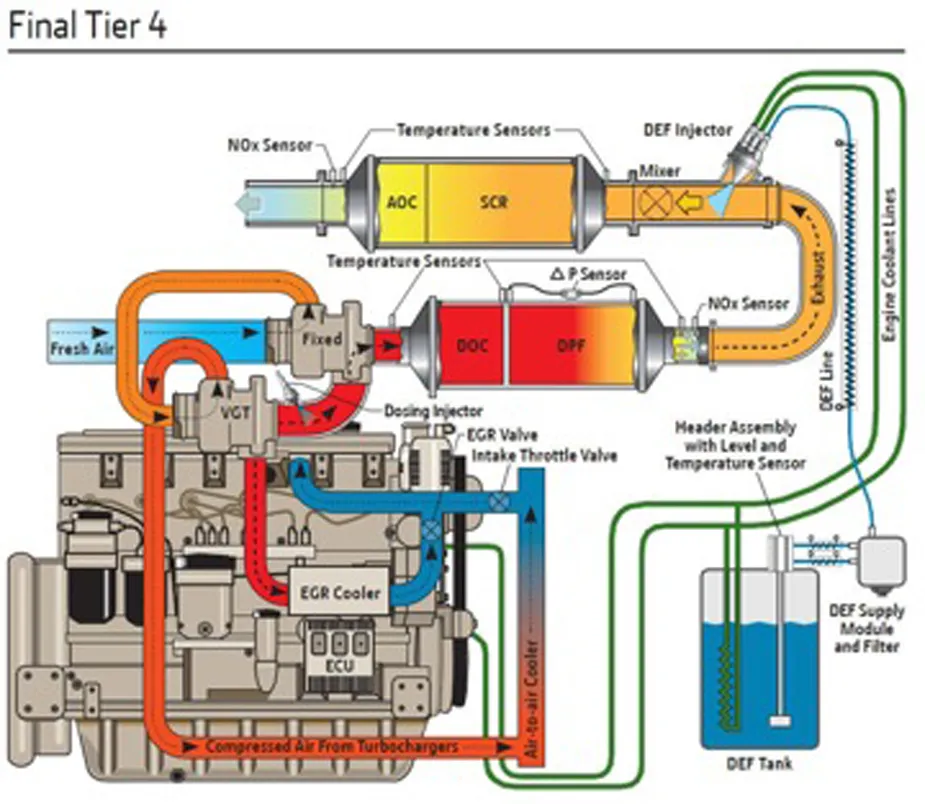

Versatile and powerful, the new ZW220-6 and ZW310-6 wheeled loaders from 233 Hitachi offer greater output than before. The machines can be used for a wide range of applications and offer greater reliability than the firm’s earlier generation models. The new Tier 4 Final/Stage IV-compliant engines do not require diesel particulate filters, lowering both maintenance costs and fuel consumption. The firm says that the ZW220-6 for example uses 7% less fuel in load and carry operations and 6% less fuel for loading than the previous model. Meanwhile the firm’s selective catalytic reduction (SCR) system is also designed to comply with EU Stage IV emission regulations.The SCR system injects urea into exhaust gas to reduce nitrogen oxide from emissions.

Other upgrades include improved visibility due to a wider field of view from the spacious cab as well as the rear-view camera. Changes to the wheel loader’s design, such as the alignment of the muffler and air intake, have also improved the rear-view visibility for the machines.

Other upgrades include improved visibility due to a wider field of view from the spacious cab as well as the rear-view camera. Changes to the wheel loader’s design, such as the alignment of the muffler and air intake, have also improved the rear-view visibility for the machines.