February 28, 2025

Read time: 1 min

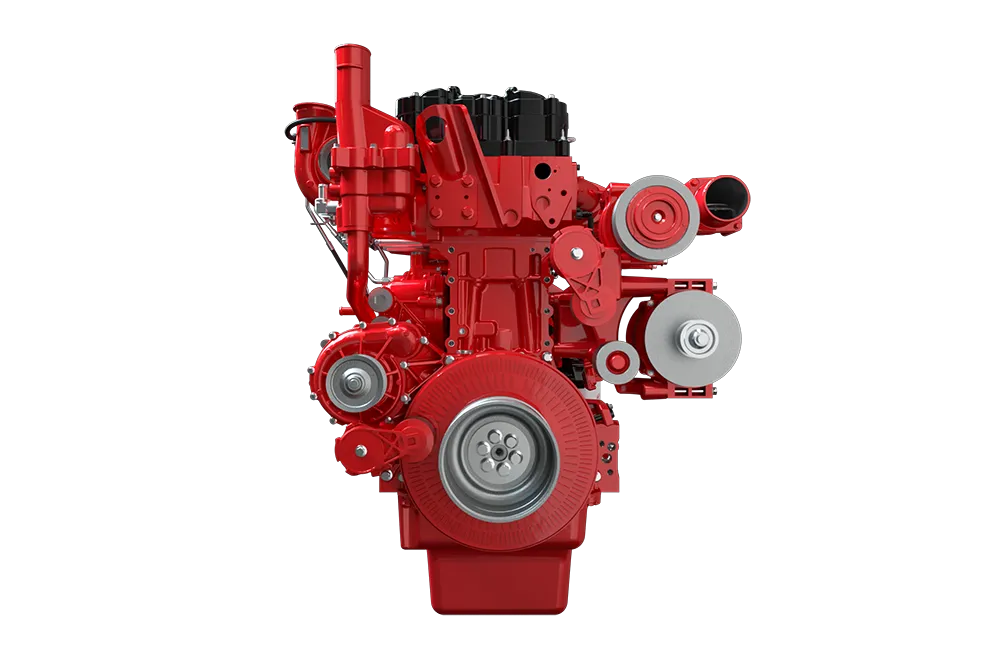

The X15 powers applications such as large construction bulldozers, cranes and excavators and is part of the Cummins HELM fuel agnostic engine platform. The platform’s new power solutions can use clean diesel, natural gas, renewable biofuels or hydrogen to ensure compatibility with evolving environmental regulations while supporting customer requirements during the energy transition.

The X15 will offer digital connectivity features, improved fuel economy and longer service intervals from its predecessor - all in a smaller package similar to that of a 13 litre engine. Ratings for the X15 will be up to 522kW and a peak torque of 3200Nm, targeted for Stage V emissions and beyond.