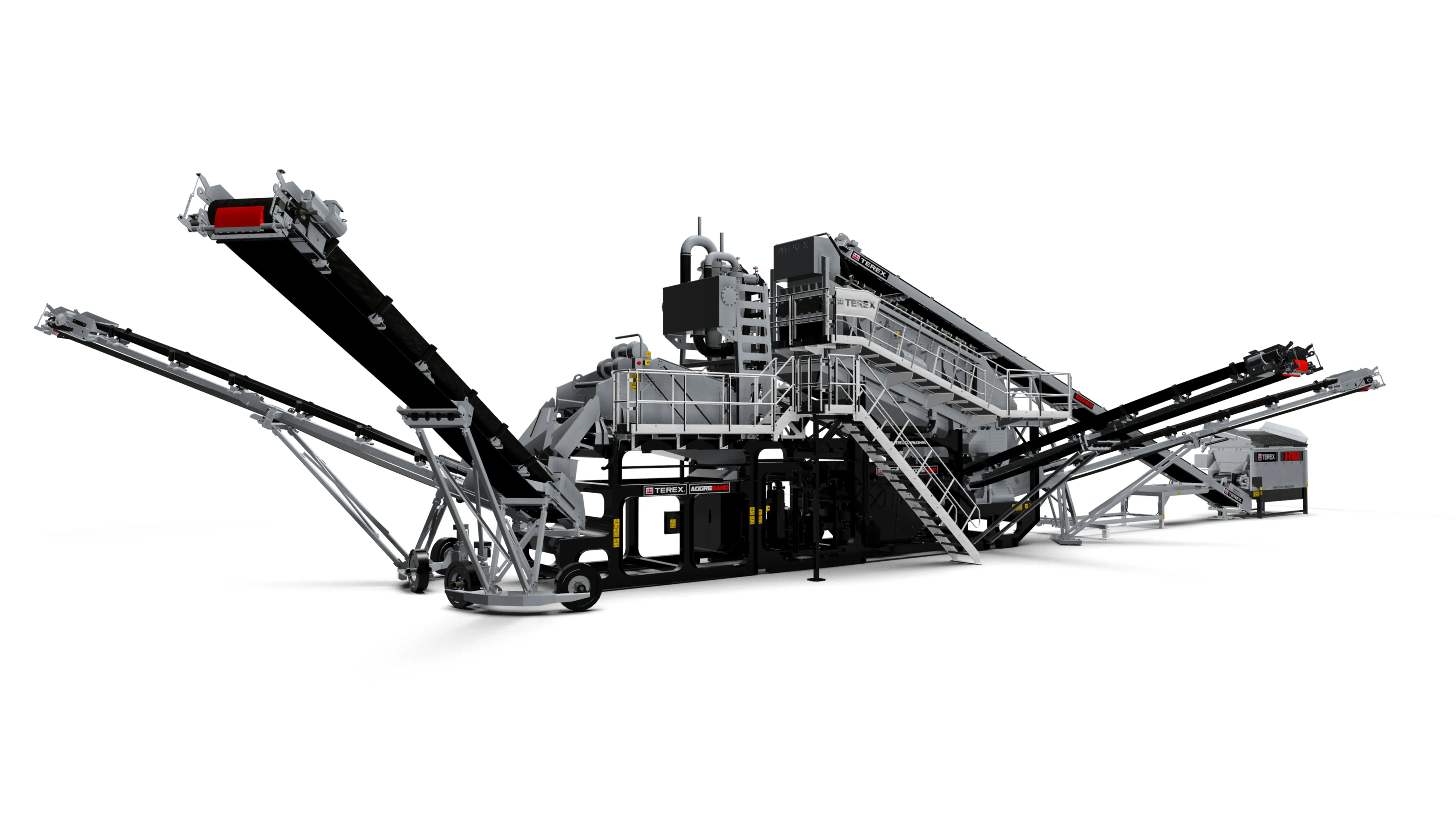

Austrian company Hartl Crusher has introduced its new 3300 Hartl Screen Plant (HSP), which is used with the company’s conveyor belts (HCB) 5000 for natural stone processing as well as the classification and refinement of recycled materials.

April 23, 2015

Read time: 1 min

Austrian company

The company says that with the hopper, the HCB can be fed from a bucket crusher or a bucket screener directly.

“The essential advantage of the HSP is the electro-hydraulic drive which provide more power than conventional electric drives,” says the company.