Hamm’s new DV+ 70i and DV+ 90i tandem rollers are said to be highly productive machines offering good visibility and easy operation. These 7tonne and 9tonne class asphalt compactors are highly versatile and have been designed so that they can be operated in either direction. To ensure a range of options for the customer, the machines are being offered in three variants: as a double vibratory roller (VV), an oscillatory roller (VO = a vibratory and oscillatory drum) and as a combination roller (VT).

January 6, 2017

Read time: 2 mins

The large cab has been designed to allow the driver to see the drum edges and edge pressing device, aided by an innovative water tank configuration. The spacious cab is said to be easy to access and offers a wide range of adjustment options, while the seat in the DV+ can be rotated by 180° in either direction, allowing a driver to face in the direction of travel for all operations.

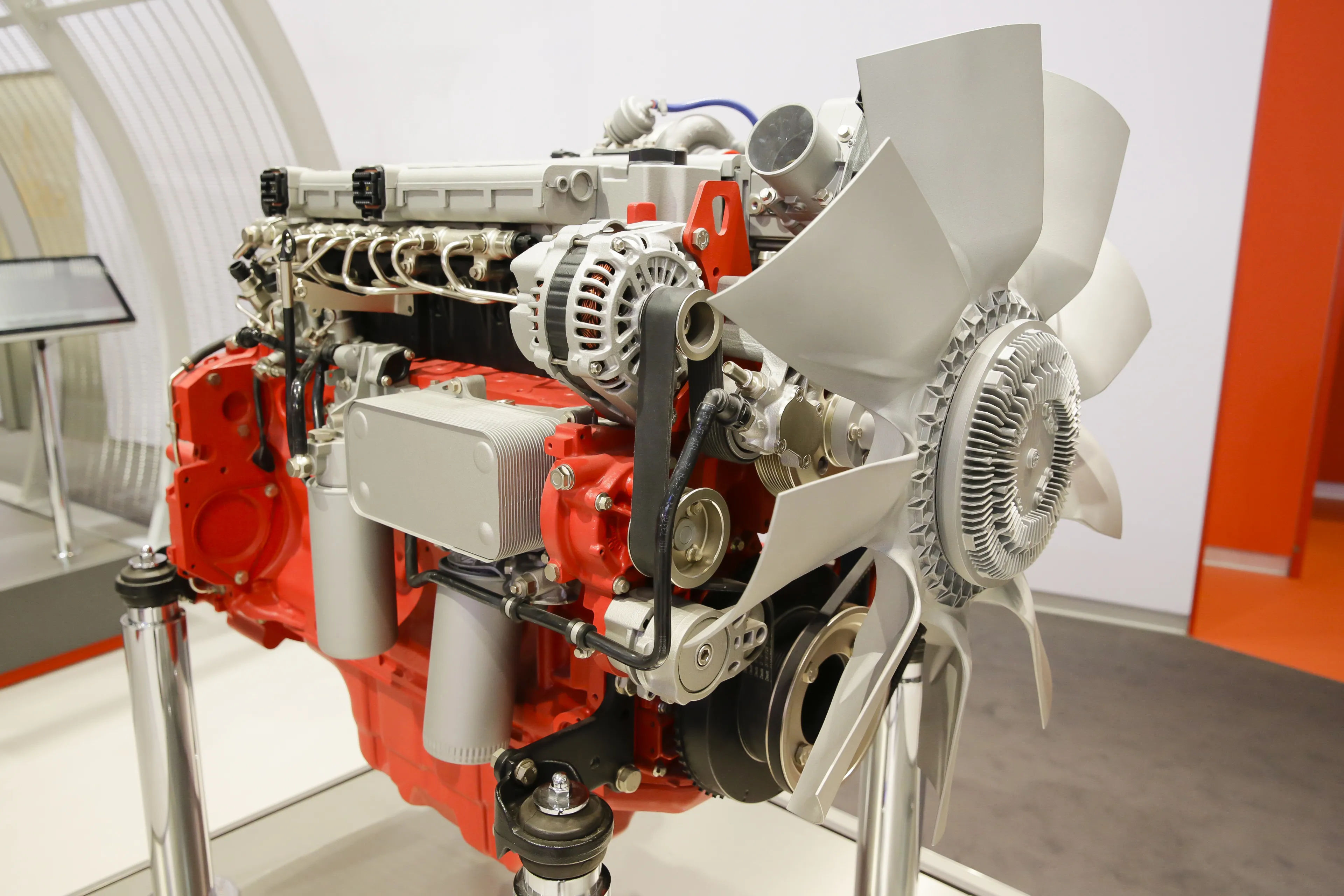

Both models are driven by the latest low emission engines, with a 75kW diesel in the DV+ 90i said to better the requirements for Tier 4 Interim/Stage IIIB legislation. Meanwhile the 56kW diesel in the DV+ 70i meets the Tier 4 Final/Stage IV requirements. Both models have diesel particulate filter (DPF) systems to remove soot particles, which also allows them to meet the tougher emissions requirements of markets such as Switzerland.

The mid-mounted engine and two-part water tank is said to optimise weight distribution, while the split drums and pivot steering allow manoeuvrability and versatility for high quality compaction even on tight corners. An automatic reverse transmission with graduated braking and acceleration helps optimise reversing, ensuring compaction is carried out without leaving bumps or hollows on the surface.