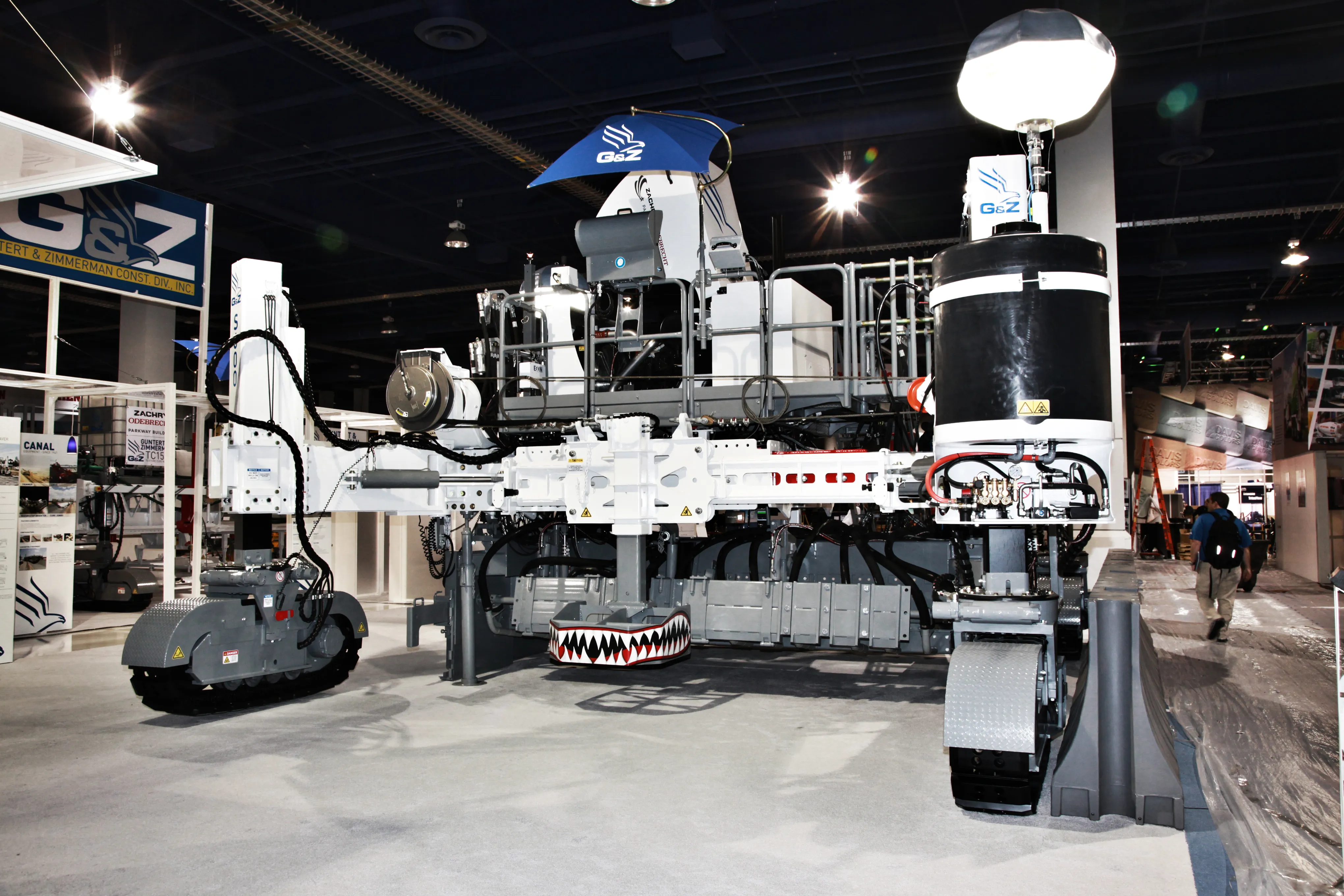

The key launch for Guntert & Zimmerman at Conexpo 2014 is the showing of its EGON IntelliMatics system. The company is also showing a number of other recent developments in the shape of its updated TC1500 Texture Cure Machine, the S600 Multi-Purpose Concrete Slipform Paver and the TeleEnd telescopic screed ends.

January 29, 2014

Read time: 2 mins

The key launch for 225 Guntert & Zimmerman at Conexpo 2014 is the showing of its EGON IntelliMatics system. The company is also showing a number of other recent developments in the shape of its updated TC1500 Texture Cure Machine, the S600 Multi-Purpose Concrete Slipform Paver and the TeleEnd telescopic screed ends.

The (equipment guidance and operation network) EGON IntelliMatics package is of particular note and allows a greater degree of telematics monitoring of the machine than with previous technology from the firm. In addition to monitoring engine functions so as to allow a contractor to address small performance issues before they become costly, this new package gives the user remote access in to all aspects of machine operation, including hydraulic and electrical functions.

By using Internet connectivity on the machine, a contractor can follow the operation of the machine remotely, using either GSM or wifi connectivity to geo-locate the paver in real-time and monitor operating parameters. The remote diagnostics mean that machine health and error codes can be tracked as well as routine service requirements. The EGON system provides continuous monitoring of operating functions, including the steering sensors and position switches and allows a contractor to view the profilograph in real-time.

In addition, the firm’s updated TC1500 Texture Cure Machine offers new relocatable jacking columns, a new cure spray hood with a quick width change feature, a new cure spray system, new standard cure tote usability and the new EGON Plus+1 Controls. The S600 Multi-Purpose Slipform Paver can be equipped with the EGON IntelliMatics and TightTrack systems. This last allows contractors to pave with only 300mm of companion lane trackline. And the novel TeleEnds can be fitted to the either end of the a paver to allow increases or reductions in pavement widths while the machine is in operation, so as to avoid obstacles such as drain covers or roadside posts.

%$Linker:2 Asset <?xml version="1.0" encoding="utf-16"?><dictionary /> 2 12791 0 oLinkExternal www.guntert.com Guntert and Zimmerman web false /EasySiteWeb/GatewayLink.aspx?alId=12791 false false %>

The (equipment guidance and operation network) EGON IntelliMatics package is of particular note and allows a greater degree of telematics monitoring of the machine than with previous technology from the firm. In addition to monitoring engine functions so as to allow a contractor to address small performance issues before they become costly, this new package gives the user remote access in to all aspects of machine operation, including hydraulic and electrical functions.

By using Internet connectivity on the machine, a contractor can follow the operation of the machine remotely, using either GSM or wifi connectivity to geo-locate the paver in real-time and monitor operating parameters. The remote diagnostics mean that machine health and error codes can be tracked as well as routine service requirements. The EGON system provides continuous monitoring of operating functions, including the steering sensors and position switches and allows a contractor to view the profilograph in real-time.

In addition, the firm’s updated TC1500 Texture Cure Machine offers new relocatable jacking columns, a new cure spray hood with a quick width change feature, a new cure spray system, new standard cure tote usability and the new EGON Plus+1 Controls. The S600 Multi-Purpose Slipform Paver can be equipped with the EGON IntelliMatics and TightTrack systems. This last allows contractors to pave with only 300mm of companion lane trackline. And the novel TeleEnds can be fitted to the either end of the a paver to allow increases or reductions in pavement widths while the machine is in operation, so as to avoid obstacles such as drain covers or roadside posts.

%$Linker: