The Pavement Robotic Pavement System consists of a battery-powered GPS-guided robot that trundles along on its four-wheels at up to 20kph. It can cover up to 7,500m² in an hour and the battery is good for up to eight hours on average. Charging time is only four hours, according to Guimu, a three-year-old start-up originating at Tsinghua University, a major research institute in the Chinese capital Beijing.

The robot is delivered to site in a specially modified truck that consists of the robot’s remote control centre. The current model is second-generation that weighs 600kg and measures 3,155mm x 1,750mm x 1,860mm. It has an upgraded obstacle avoidance system with a range of up to 3m.

The majority of the robot’s work is along airport runways, including those of Beijing International. It has ground penetrating radar in front and a high-resolution camera at back. This allows visual inspection of runways and roads with a resolution of up to 1mm as well as 3D modelling of pavement structures, roadbeds and roadside utilities such as pipelines. Inspection depth can be between 1m and 3m.

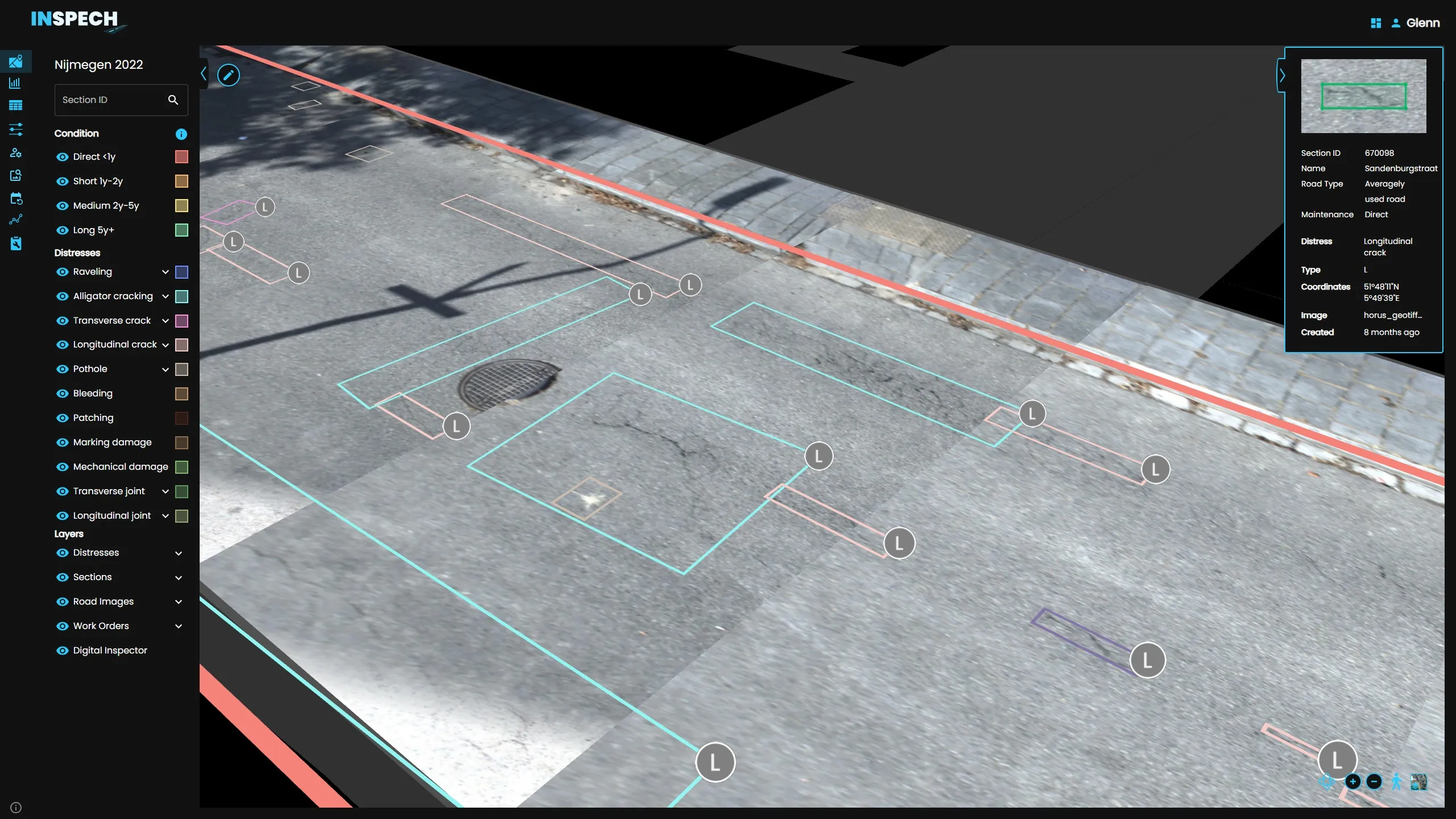

Analysis can detect voids, cable ducts, looseness, hollows, sedimentation, cracks and subgrade moisture. Detection results can be customised to access the road’s information management system.

Guimu will sell the system but the company operates it as an on-demand service at most of the 49 sites in China where the robots work.