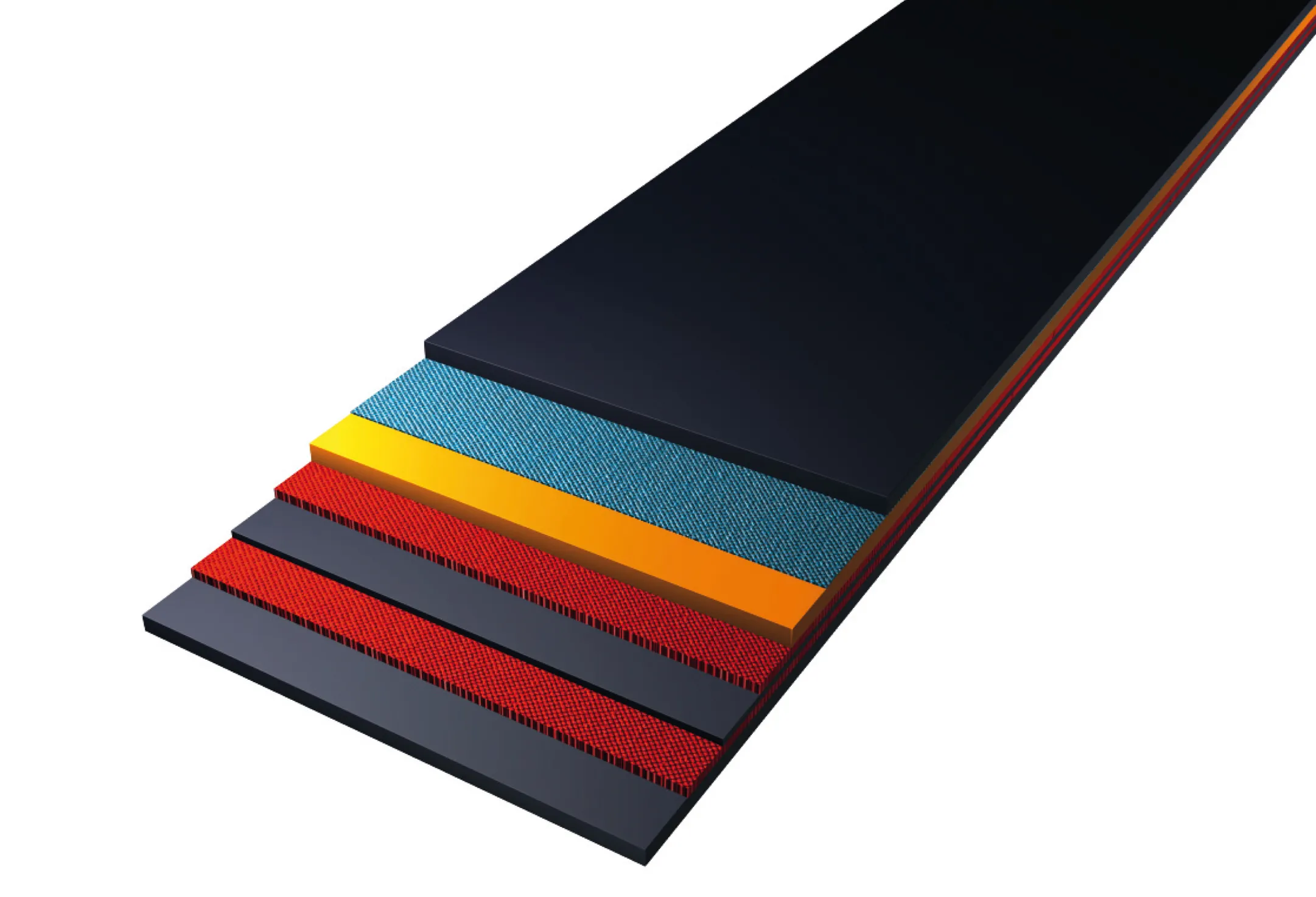

GreyStone, which offers a comprehensive line of portable and semi-portable aggregate equipment, is highlighting its new products including the recently released Unibody fine material washing screw.

The company says that the Unibody can be set up quickly, and consistently delivers thoroughly-cleaned aggregate, saving time and money.

A one-piece body design, fabricated using ASTM A36-certified structural steel, allows the 25ft x 36inch (1m) Unibody to be moved without the need for extra highway permits.

January 6, 2017

Read time: 1 min

The company says that the Unibody can be set up quickly, and consistently delivers thoroughly-cleaned aggregate, saving time and money.

A one-piece body design, fabricated using

%$Linker: