Pipeline & Drainage Systems (PDS) intends to boost its market presence with its novel kerb, bridge and channel drainage products. The latest addition to the line-up is the Envirodeck system, which takes over from the well-accepted and well-proven Hydrodeck range. Envirodeck uses similar technology to the firm's existing

February 6, 2012

Read time: 2 mins

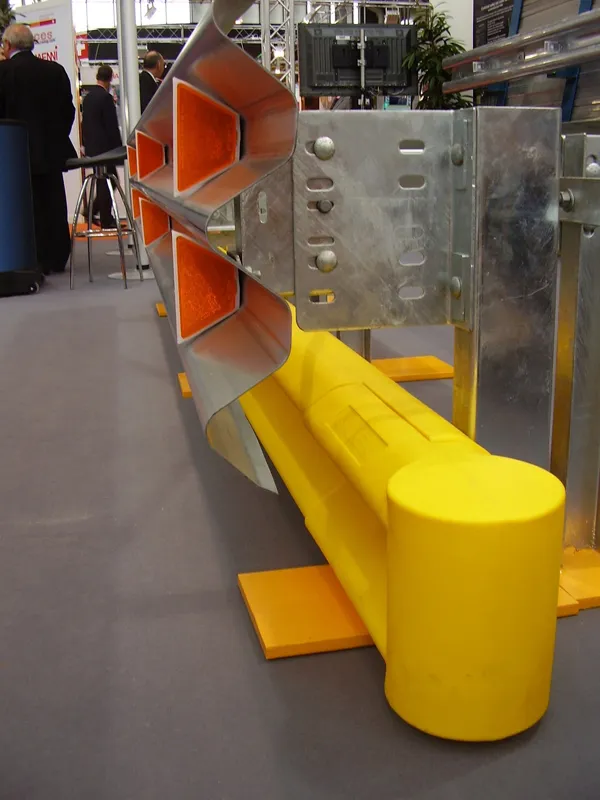

Pipeline & Drainage Systems (PDS) intends to boost its market presence with its novel kerb, bridge and channel drainage products. The latest addition to the line-up is the Envirodeck system, which takes over from the well-accepted and well-proven Hydrodeck range. Envirodeck uses similar technology to the firm's existing Envirokerb products, which are durable but lightweight kerb drainage units made from recycled materials. Like the earlier and highly successful Hydrodeck units, the Envirodeck system is aimed at use in bridge drainage applications. However, the heavier and more costly ductile iron Hydrodeck units are being replaced by the lightweight Envirodeck system, which is made from durable composite materials. PDS is seeing its market share continue to grow and is manufacturing the Envirodeck units in the UK and China.

The firm has also made extensive use of Business Assurance services provided by LRQA at UK locations and manufacturing plants in Asia, to ensure that the products meet international standards as well as using other services provided by the firm. Initially, a local supplier of certification services was employed in China. However, PDS switched to LRQA when it became necessary to streamline business systems across all sites and when issues became apparent in complying with the standard for drainage channels for vehicular and pedestrian areas (EN 1433).

Following input from LRQA, PDS was able to revise its operations and meet necessary standards. As well as complying with the drainage channel standard, PDS implemented other changes to gain ISO 9001 as well as the European CE mark, allowing the products to be supplied in EU nations. PDS has also used LRQA assessors at two plants in China and one in the UK to help implement quality standards in manufacturing processes. With the CE mark, PDS has been able to secure new business with the1441 UK Highways Agency, local authorities and customers in Italy, Germany, Spain and the Czech Republic. Increasing efficiency and reducing waste along with the gains in market share have resulted in a 30% increase in annual revenue.

The firm has also made extensive use of Business Assurance services provided by LRQA at UK locations and manufacturing plants in Asia, to ensure that the products meet international standards as well as using other services provided by the firm. Initially, a local supplier of certification services was employed in China. However, PDS switched to LRQA when it became necessary to streamline business systems across all sites and when issues became apparent in complying with the standard for drainage channels for vehicular and pedestrian areas (EN 1433).

Following input from LRQA, PDS was able to revise its operations and meet necessary standards. As well as complying with the drainage channel standard, PDS implemented other changes to gain ISO 9001 as well as the European CE mark, allowing the products to be supplied in EU nations. PDS has also used LRQA assessors at two plants in China and one in the UK to help implement quality standards in manufacturing processes. With the CE mark, PDS has been able to secure new business with the