That includes hydrotreated vegetable oil (HVO). The fuel has been approved for use in all Ammann diesel-burning machines. In addition, new ABG Pavers arrive filled with HVO.

HVO is a biofuel made from waste, such as animal fat or processed vegetable oils. It is classified as a renewable diesel and renowned for having a longer shelf life than other biodiesels.

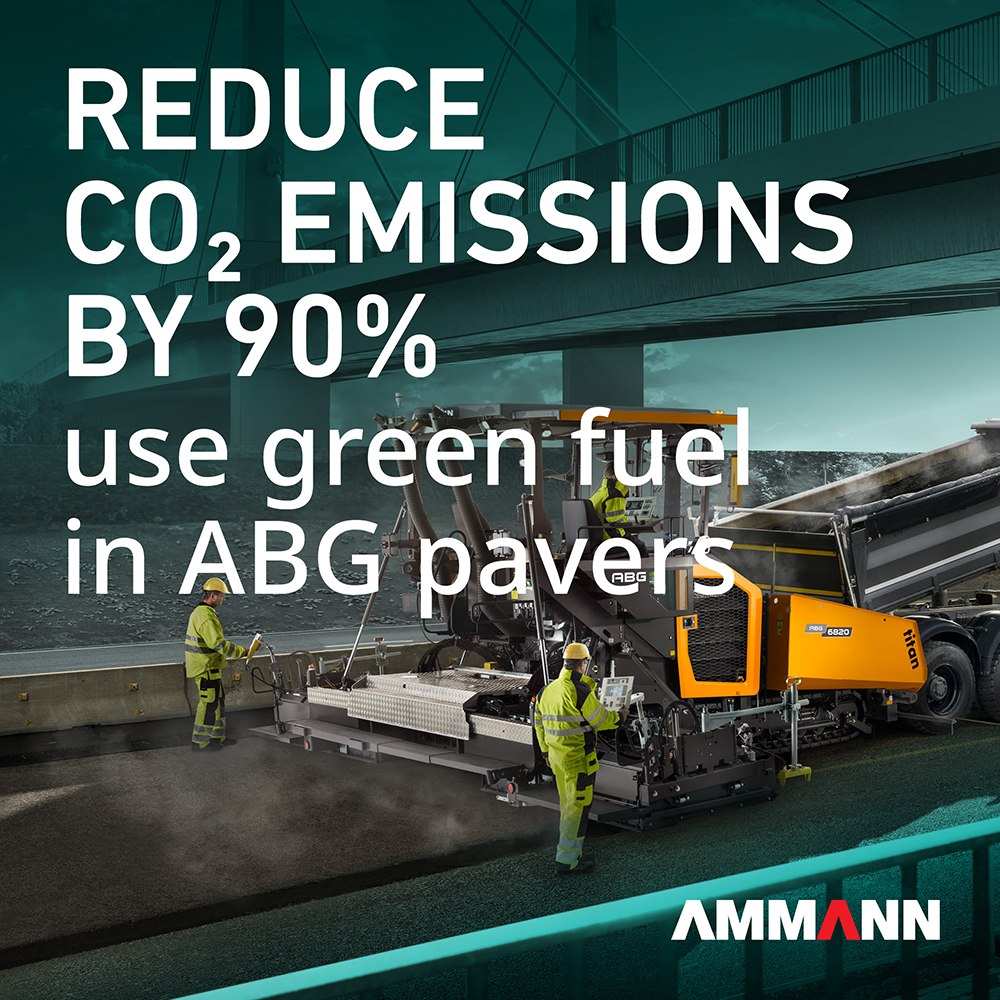

HVO reduces gas CO2 emissions by up to 90%, with no additional costs. Every 1000 litres of standard diesel fuel burned produces ca. 2640 kg of greenhouse gas CO2, compared to just 260 kg of greenhouse gas CO2 for every 1000 litres of HVO burned.

HVO-compatible Ammann machines require no engine modifications to burn the fuel. In addition, HVO provides the same performance as diesel fuel while reducing the particulate matters that require maintenance.

“Businesses can see some advantages in terms of maintenance, while also seeing big improvements in their sustainability efforts,” said Alex Lamers, ESG Officer at Ammann. “This is important not only for the greater public good, but also essential as governments continue to tighten regulations and push for greener alternatives.

HVO can be utilised in most Ammann machines that burn diesel fuel. Among the HVO-compatible Ammann products are:

HVO can be utilised in most Ammann machines that burn diesel fuel. Among the HVO-compatible Ammann products are:

• Vibratory plates (forward, reversible and hydrostatic)

• Walk-behind rollers

• Trench rollers

• Soil compactors

• Tandem rollers (articulated, pivot-steer and pneumatic)

• ABG Pavers

Additional information on HVO can be found at:

DE - HVO100 - der umweltfreundliche Kraftstoff

EN - Europe: HVO 100 available in eight European countries | SGS Inspire

Click here to find out more.

Content produced in association with Ammann