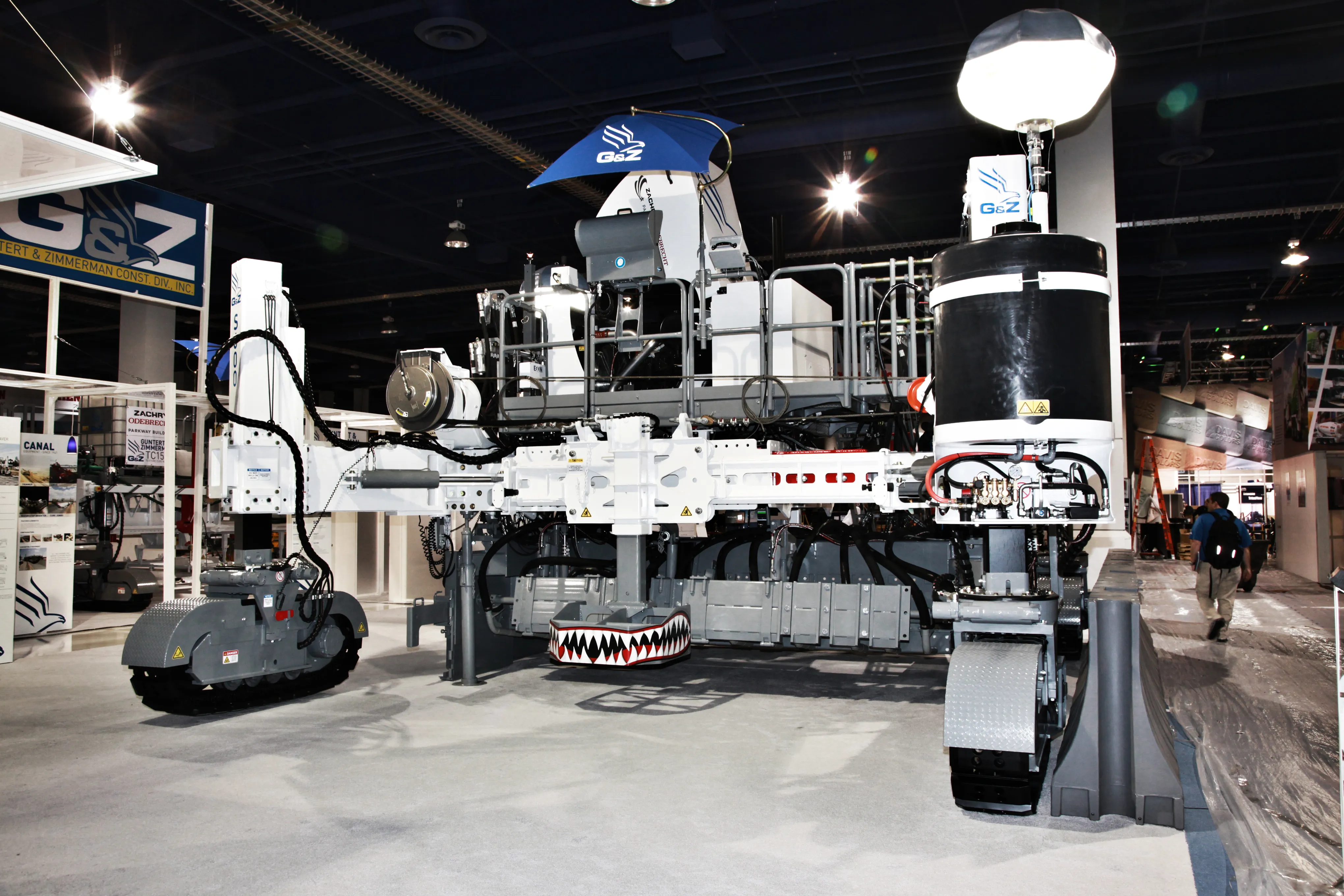

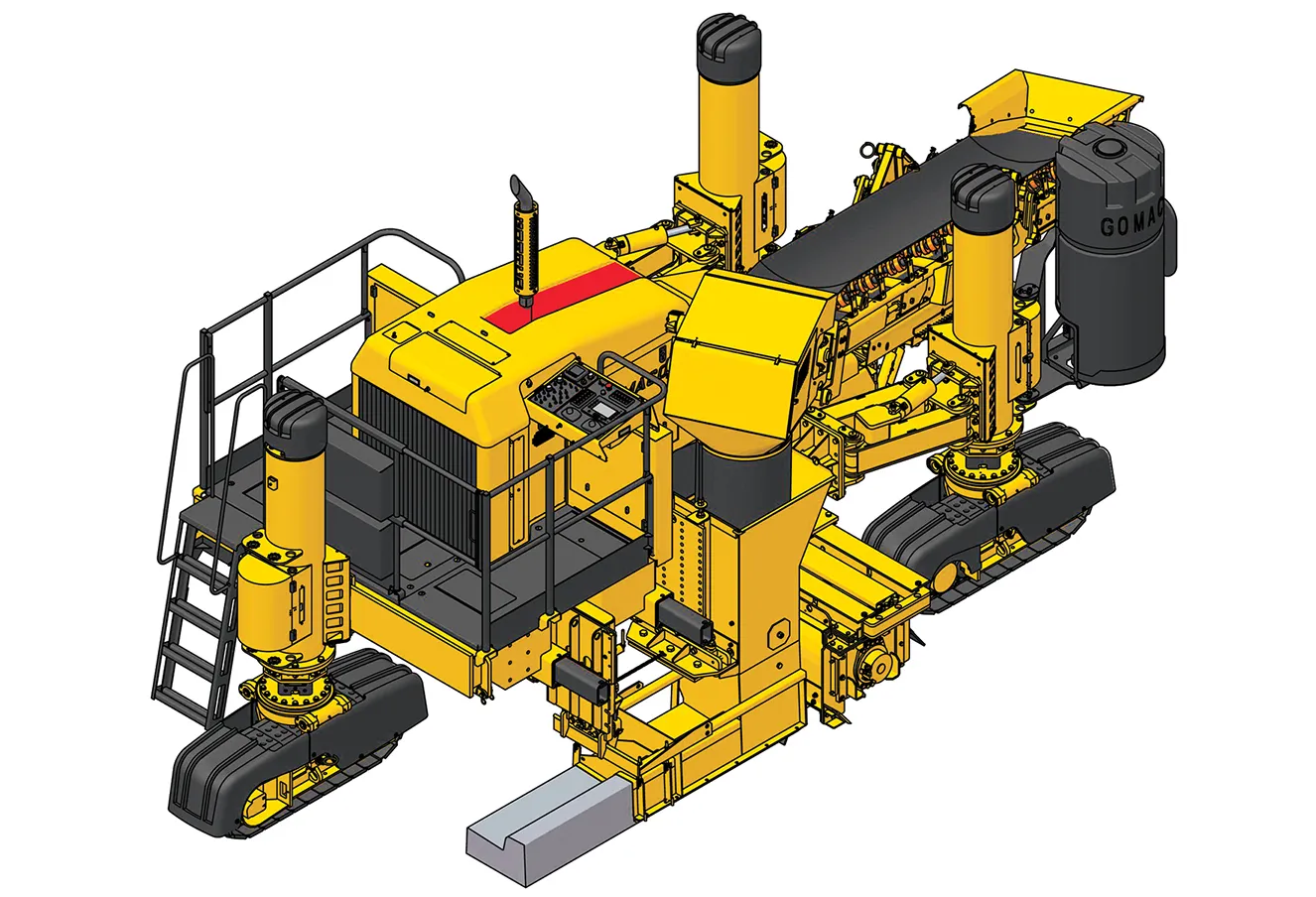

GOMACO says that its new 3300 multi-application slipform paver is both smart and versatile. The 3300 features tight steering capabilities with smart leg and track positioning, as well as a smart telescoping mold mounting system that allows paving on the right side or left side. The firm’s GT-3300 has now been re-engineered with the latest technology such as the new version of the G+ control system. GOMACO’s 3300 was specifically designed for right side and left side pour capabilities and features a symmetri

March 2, 2016

Read time: 2 mins

The 3300’s tight steering is achieved with hydraulic rotational drives on the tracks and G+ controls. The 3300’s two front legs are mounted on parallelogram-style pivot arms and the rear leg has power slide for positioning. The smart leg positioning is accomplished with smart cylinders and the G+ digital control system along with smart track rotation to provide the G+ control system with the exact location and position of the tracks and reference to the straight ahead line. Another feature is the smart telescoping mold mounting system for reference to G+ for repeatable mold offset. It has the GOMACO Hook-and-Go mold mounting system to change from one mold profile to the next. The trimmerhead and mold sideshift and vertically-adjust to clear obstacles which allows the 3300 to pave right up to obstacles. The G+ control system interfaces with stringline or a 3D guidance system for the 3300 multi-application paver.