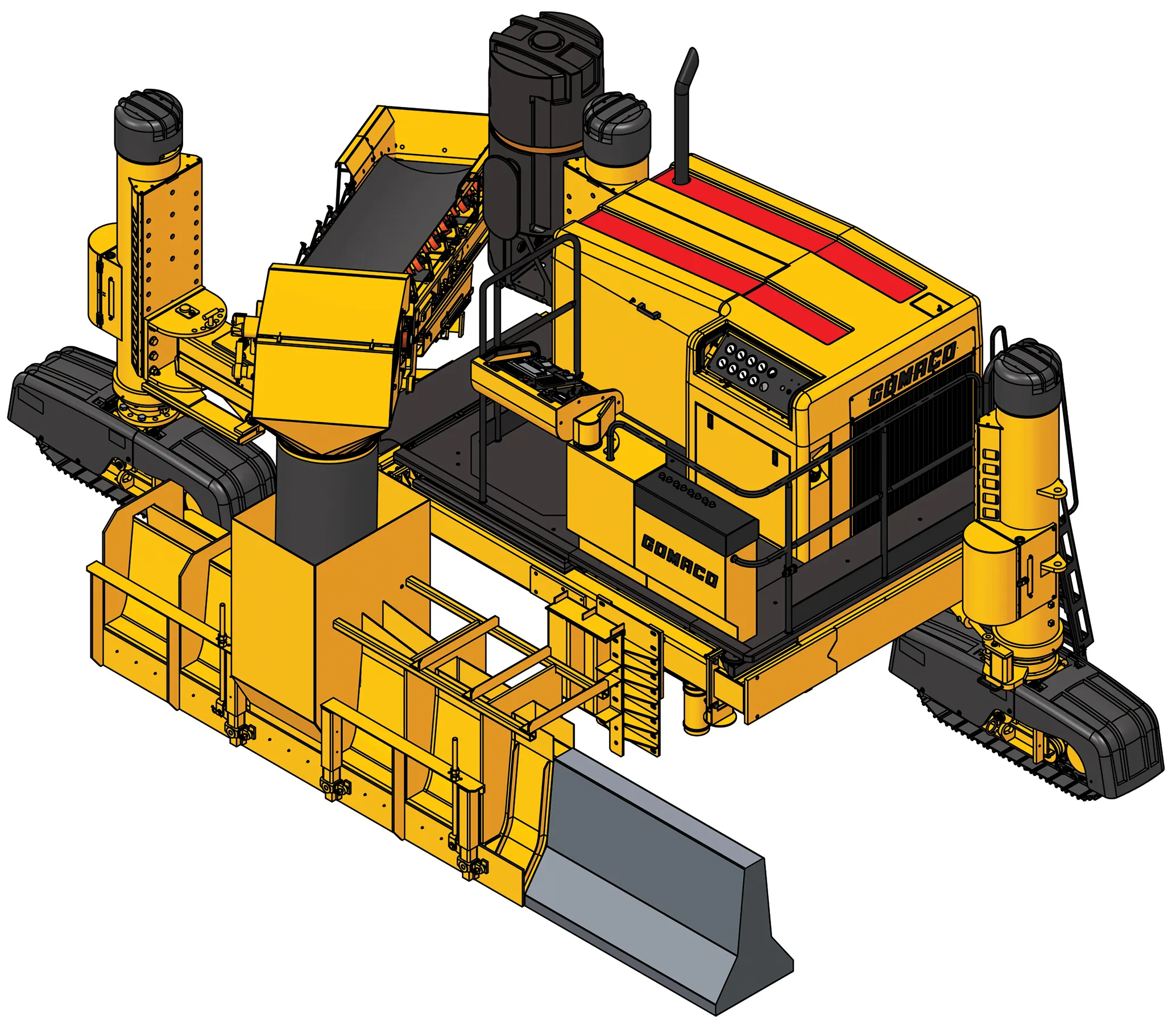

GOMACO says that a series of improvements to the Commander III slipform paver help increase its versatility and overall performance. The machine will be on the market in the third quarter of this year and the tree track machine’s key improvements include the new G+ control system and the latest low emission

February 24, 2014

Read time: 2 mins

The firm redesigned the frame to accommodate Tier 4 engines and their cooling packages. The engine installation has been reversed so as to improve operator visibility while the new engine cover gives better access to service and fill points. Another new feature is an optional on-board camera that can be located anywhere on the machine and provide the operator with a view of a working function on the display of the G+ system. The machine has the new GBox on every leg, which improves control of the steering and grade through the G+ system.

www.gomaco.com