TrafFix Devices, a US global manufacturer and supplier of traffic control devices and crash attenuators, is offering the Water Wall, a temporary safety delineator.

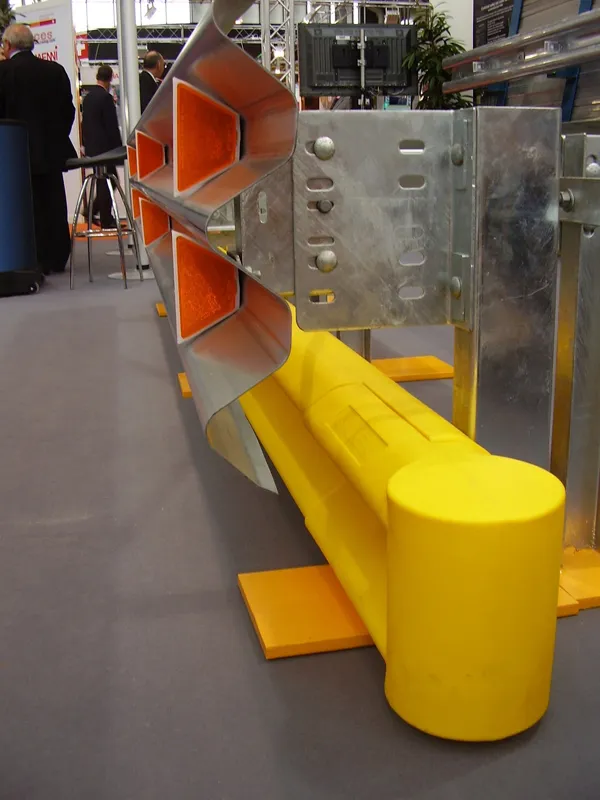

The Water Wall is a MASH-eligible TL-2 longitudinal channelising device that provides critical protection in work zones by clearly delineating spaces while maintaining optimal visibility for drivers. Its 812mm (32-inch) tall by 1,829mm (72-inch) long low-profile ensures clear sightlines at intersections which improves traffic awareness and reduces accident risks.

TrafFix Devices says that the Water Wall is manufactured from durable low-density polyethylene plastic which makes is it built for longevity and resistant to cracks and breakage, even in demanding conditions. Its double-wall knuckle design reinforces hinge points, reducing the risk of structural failure. The hinge allows up to 30 degrees of pivoting.

Meanwhile, the positive separation system can be adjusted to fit various layouts, while a new corner piece enables 90-degree turns for even greater versatility.

The Water Wall includes a 203mm (8-inch) fill hole with a twist-lock plastic cap for a faster filling process and a tamper-resistant offset drain plug that secures or releases in just two-and-a-half turns. A steel connection and keeper pin system ensures secure interlocking between sections, while molded-in forklift and pallet jack slots allow for easy transport and positioning.

For added security, the Water Wall is compatible with the company’s Water-Wall chain-link fence attachment, providing an additional layer of protection when necessary.

Designed to meet rigorous safety standards, the Water Wall has been NCHRP-350 tested and passed to MASH (Manual for Assessing Safety Hardware) TL-1 Barrier Wall, TL-2 Longitudinal Channelising Device and TL-3 Barricade.

It also seamlessly connects to the SLED end treatment, eliminating the need for additional shielding or flaring, further simplifying deployment. SLED is the ‘sentry longitudinal energy dissipater’, a narrow water-filled non-redirective gating crash cushion that is a MASH tested, passed and eligible.

TrafFix Devices, with 39 years of experience, is based in San Clemente in the US state of California. The company designs and manufactures products that comply with international highway safety regulations, providing effective solutions for traffic management and accident prevention.