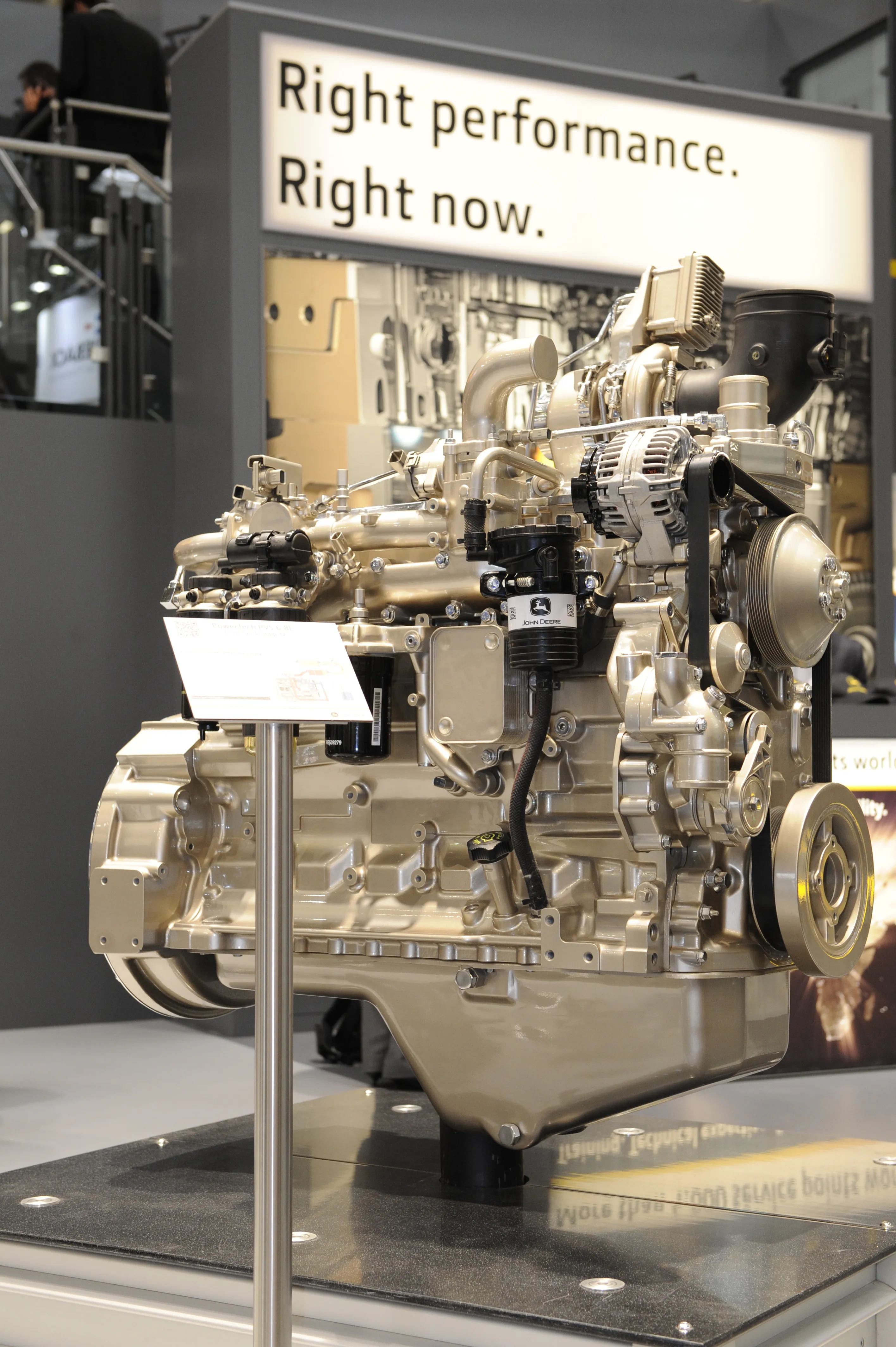

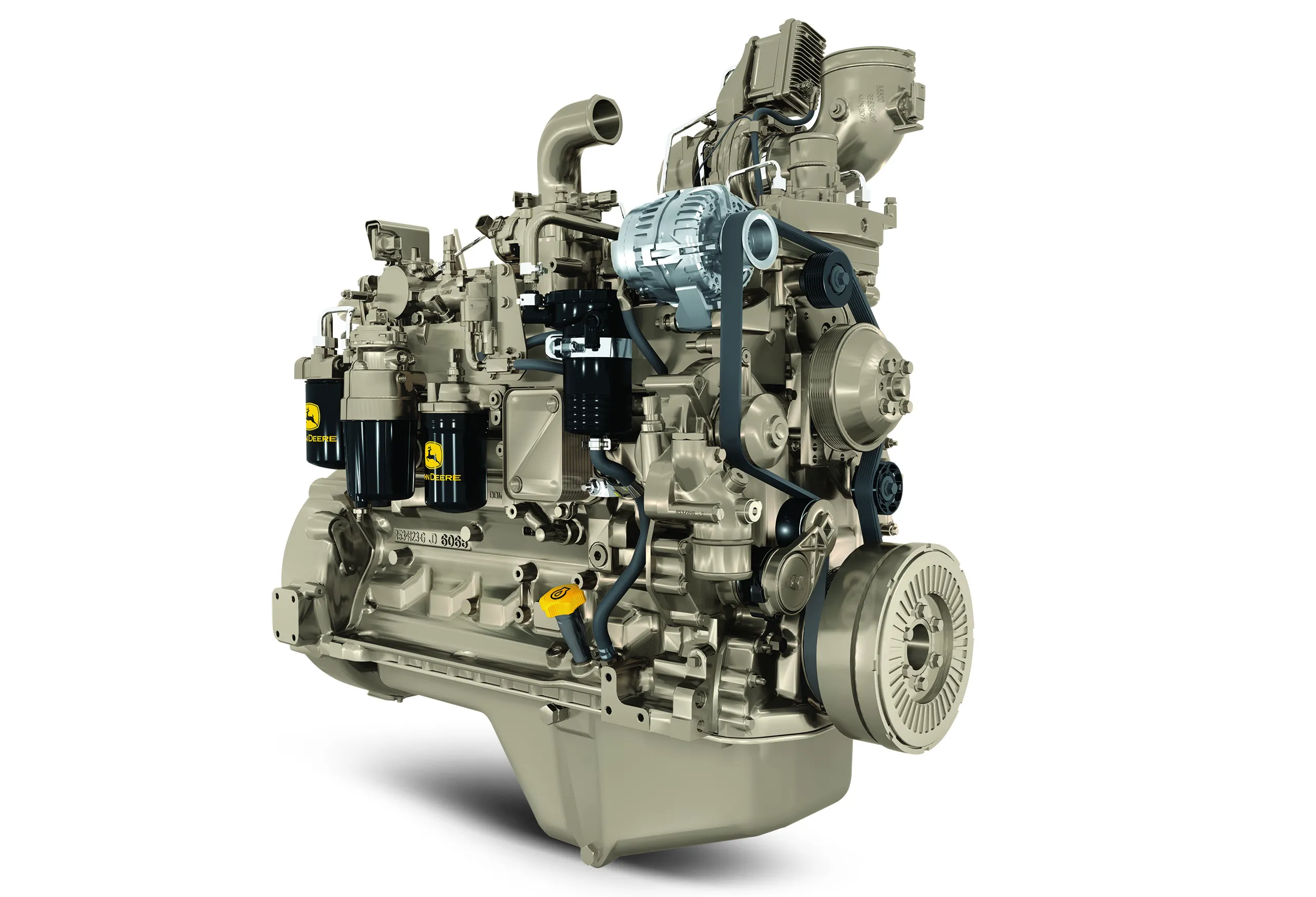

Engine manufacturer Deutz is unveiling TCD2.2 diesel and gas engines, along with gas versions of the existing TCD2.9. The three-cylinder 2.2-litre engine offers power ratings of up to 55kW (74hp) with diesel power and a maximum of 42kW (56hp) with gas and have been designed specifically for compact construction and materials handling applications. The TCD2.2 will go into series production in time for Stage V emissions standards in 2019.

Deutz is also making a gas version of its popular four-cylinder, 2.9-l

January 6, 2017

Read time: 2 mins

Engine manufacturer 201 Deutz is unveiling TCD2.2 diesel and gas engines, along with gas versions of the existing TCD2.9. The three-cylinder 2.2-litre engine offers power ratings of up to 55kW (74hp) with diesel power and a maximum of 42kW (56hp) with gas and have been designed specifically for compact construction and materials handling applications. The TCD2.2 will go into series production in time for Stage V emissions standards in 2019.

Deutz is also making a gas version of its popular four-cylinder, 2.9-litre TCD2.9 available. The gas engine will produce up to 55kW (74hp). Both of the gas engines will be equipped with three-way catalytic converters, while there is no requirement for after-treatment to meet the next emissions stage.

“Our new gas engines as well as expanding our power output range, are helping us to exploit the growing potential offered by alternative fuels,” said board of management member Michael Wellenzohn.

DeutZ has confirmed that its full range of TCD diesel engines will be Stage V ready in 2019. The four-cylinder TCD 2.9, 3.6 and 4.1 engines, along with the six-cylinder TCD6.1 and 7.8 will use a diesel oxidation catalyst, diesel particulate filter and selective catalytic reduction to meet the new standard. The company said that all of the engines will maintain their current packaging dimensions, making it easy for OEM to install Deutz engines into their machinery with no changes required to meet the next stage of emissions regulation.

Deutz is also making a gas version of its popular four-cylinder, 2.9-litre TCD2.9 available. The gas engine will produce up to 55kW (74hp). Both of the gas engines will be equipped with three-way catalytic converters, while there is no requirement for after-treatment to meet the next emissions stage.

“Our new gas engines as well as expanding our power output range, are helping us to exploit the growing potential offered by alternative fuels,” said board of management member Michael Wellenzohn.

DeutZ has confirmed that its full range of TCD diesel engines will be Stage V ready in 2019. The four-cylinder TCD 2.9, 3.6 and 4.1 engines, along with the six-cylinder TCD6.1 and 7.8 will use a diesel oxidation catalyst, diesel particulate filter and selective catalytic reduction to meet the new standard. The company said that all of the engines will maintain their current packaging dimensions, making it easy for OEM to install Deutz engines into their machinery with no changes required to meet the next stage of emissions regulation.