Frost Controls Systems, based in the US state of Indiana, installs and maintains non-invasive, non-contact IoT (Internet of Things) sensors and pairs them with software packages.

The integrated cameras within the company’s Mini RWIS help confirm road conditions and improve the efficiency of local road maintenance, especially in winter.

Many communities are reliant on air temperature data to determine treatment plans because they don’t have access to surface temperature data. This becomes a problem when surface temperature must be known to accurately assess how much salt is needed to provide the safest travel.

Once road temperatures start dropping below around -7C (20°F), salt starts becoming less effective. But not all roads within the same ambient air temperature region will cool the same. Frost Control Systems says that its RWIS allows workers to see that only one area of the community needs their roads treated.

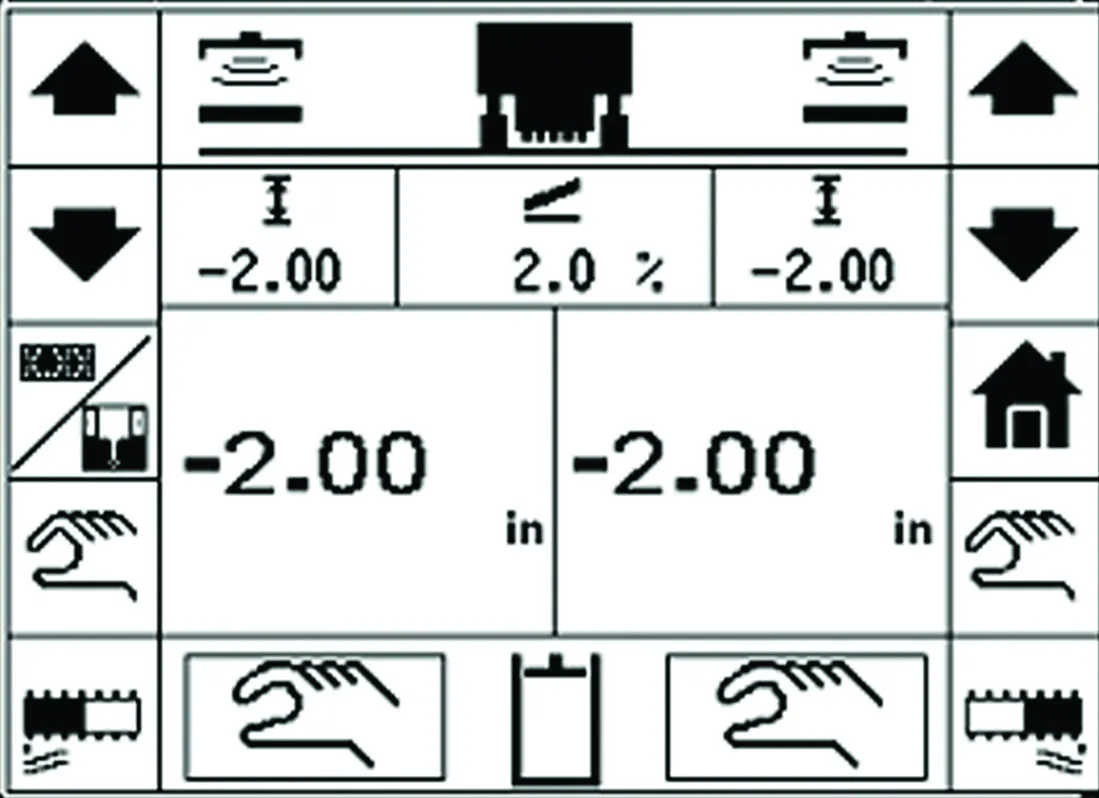

The Mini RWIS monitors air temperature, road temperature, dewpoint and humidity. Also, every 20 minutes, each sensor sends an image from its location to accompany the system’s regular data package in order to provide maximum insight as to what road conditions are.

The sensors can be mounted to most common support structures, be they wood, concrete or metal, in under 20 minutes thanks to stainless steel banding and clips. If this is not needed, the sensors can be installed directly to utility poles with the correct size lag screws and a cordless drill.

Power for the sensor is by either a direct mains hook-up or by installed battery that makes the system suitable for remote locations with no power.

An internal roaming SIM card identifies the best signal and sends the data packages. Cloud-based software organises data, sends alerts and displays charts. Local authority employees can monitor conditions and receive alerts on desktop and mobile devices.

All information collected by the Mini RWIS can be easily accessed through a dashboard including historical data access, data charts and sensor maps. From the dashboard is where each sensor can be monitored and all alert settings can be customised for maximum efficiency.

The company said that it plans to work with Michigan’s Muskegon County Road Commission next year to test snow depth sensors. Laser rangefinders are one of the ways to achieve extreme accuracy, but it will likely be a combination of laser and acoustic technology that will be tested, noted the company.