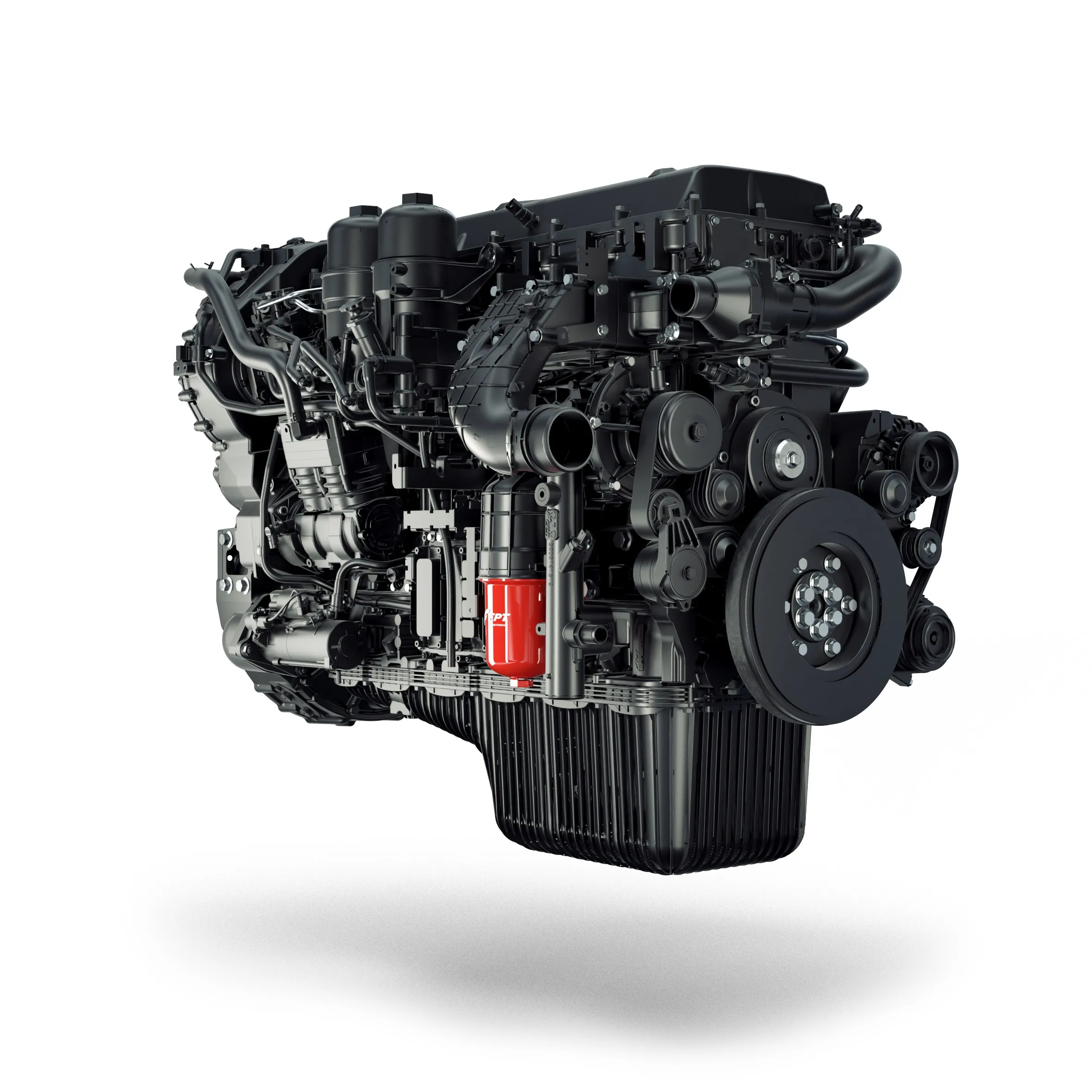

Versatility is claimed by FPT Industrial for its new XCURSOR 13 internal combustion engine. The XCURSOR 13 is FPT Industrial’s first multi-fuel single base engine designed to run fuels ranging from diesel and natural gas – including biomethane to provide net-zero emissions – to hydrogen and renewable fuels. The engine offers compatibility with a wide range of market requirements and different vehicle installations. The XCURSOR 13 is a primary contributor to achieving CO2 emissions targets, and one of the most significant parts of FPT Industrial’s decarbonisation program. This is based on a multi-energy approach and driven by the end goal of providing its customers with the best ready-to-install products.

Starting from a common core, the engine is based on an improved 13litre engine architecture to meet current CO2 reduction targets and be ready for future regulations. The latest versions of the XCURSOR 13 cover multiple segments and on- and off-road missions, combining high performance with reduced weight and fuel consumption, as well as extended durability and reduced TCO.