Powertrain manufacturer FPT Industrial will display its latest solutions for construction applications, including its new flagship engine, the Cursor 16, which “delivers 18litre performance in a 13litre package.”

FPT, a brand of CNH Industrial, says its range for the construction sector is very broad, from 33-570kW, lately revamped with the state-of-the-art Cursor 16 engine for heavy-duty applications.

The Cursor 16 is the company’s biggest solution for the world of construction and is compliant to Ti

January 29, 2015

Read time: 2 mins

Powertrain manufacturer 7935 FPT Industrial will display its latest solutions for construction applications, including its new flagship engine, the Cursor 16, which “delivers 18litre performance in a 13litre package.”

FPT, a brand of CNH Industrial, says its range for the construction sector is very broad, from 33-570kW, lately revamped with the state-of-the-art Cursor 16 engine for heavy-duty applications.

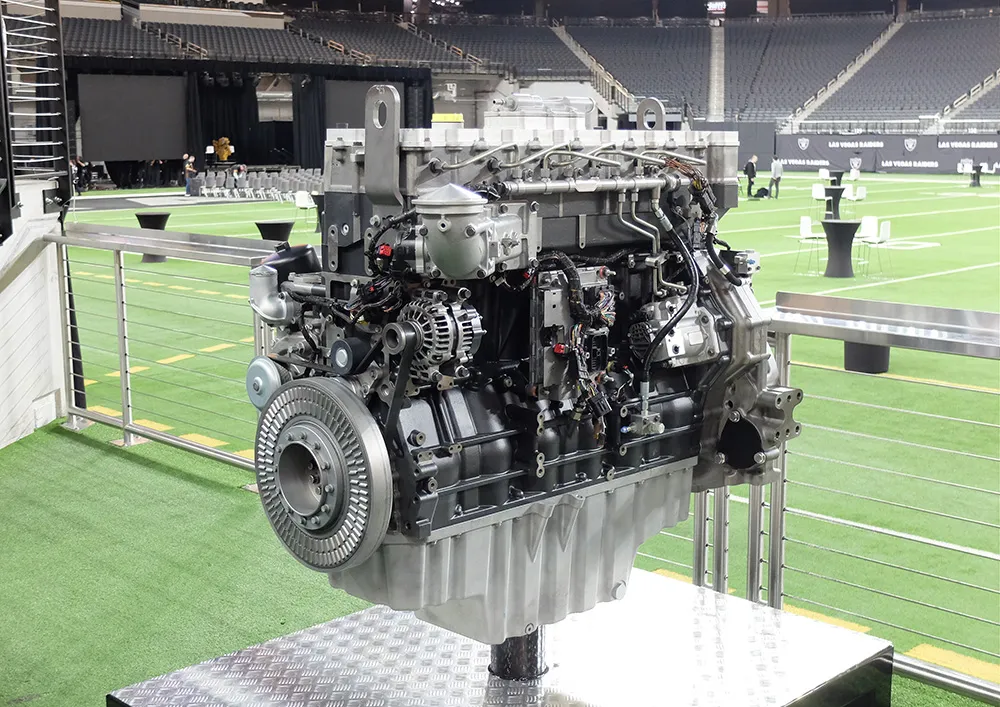

The Cursor 16 is the company’s biggest solution for the world of construction and is compliant to Tier 4B/Stage IV emissions standards thanks to the patented HI-eSCR system. It is the first FPT Industrial engine to adopt a Compact Graphite Iron (CGI) cylinder head, a high performance material providing high thermal and mechanical resistance, and the engine features a third generation common rail system of up to 2,200bar under cover.

The engine delivers power outputs of up to 570 kW with maximum torque of 3,320Nm at 1,500 rpm in its single stage version and up to 630kW with maximum torque of 3,500Nm at 1,400 rpm when available in its double stage version.

The Cursor 16 is specifically suitable for large construction and material handling equipment, such as wheeled loaders, excavators, cranes and dumpers.

Among other engines on display, and smallest in the FPT range, is the customisable R22, developed in partnership with Italian VM Motori. It is able to comply with Tier 4B/Stage IIIB emission regulations, and is suitable mainly for construction machines including skid steer loaders and mini excavators.

FPT, a brand of CNH Industrial, says its range for the construction sector is very broad, from 33-570kW, lately revamped with the state-of-the-art Cursor 16 engine for heavy-duty applications.

The Cursor 16 is the company’s biggest solution for the world of construction and is compliant to Tier 4B/Stage IV emissions standards thanks to the patented HI-eSCR system. It is the first FPT Industrial engine to adopt a Compact Graphite Iron (CGI) cylinder head, a high performance material providing high thermal and mechanical resistance, and the engine features a third generation common rail system of up to 2,200bar under cover.

The engine delivers power outputs of up to 570 kW with maximum torque of 3,320Nm at 1,500 rpm in its single stage version and up to 630kW with maximum torque of 3,500Nm at 1,400 rpm when available in its double stage version.

The Cursor 16 is specifically suitable for large construction and material handling equipment, such as wheeled loaders, excavators, cranes and dumpers.

Among other engines on display, and smallest in the FPT range, is the customisable R22, developed in partnership with Italian VM Motori. It is able to comply with Tier 4B/Stage IIIB emission regulations, and is suitable mainly for construction machines including skid steer loaders and mini excavators.