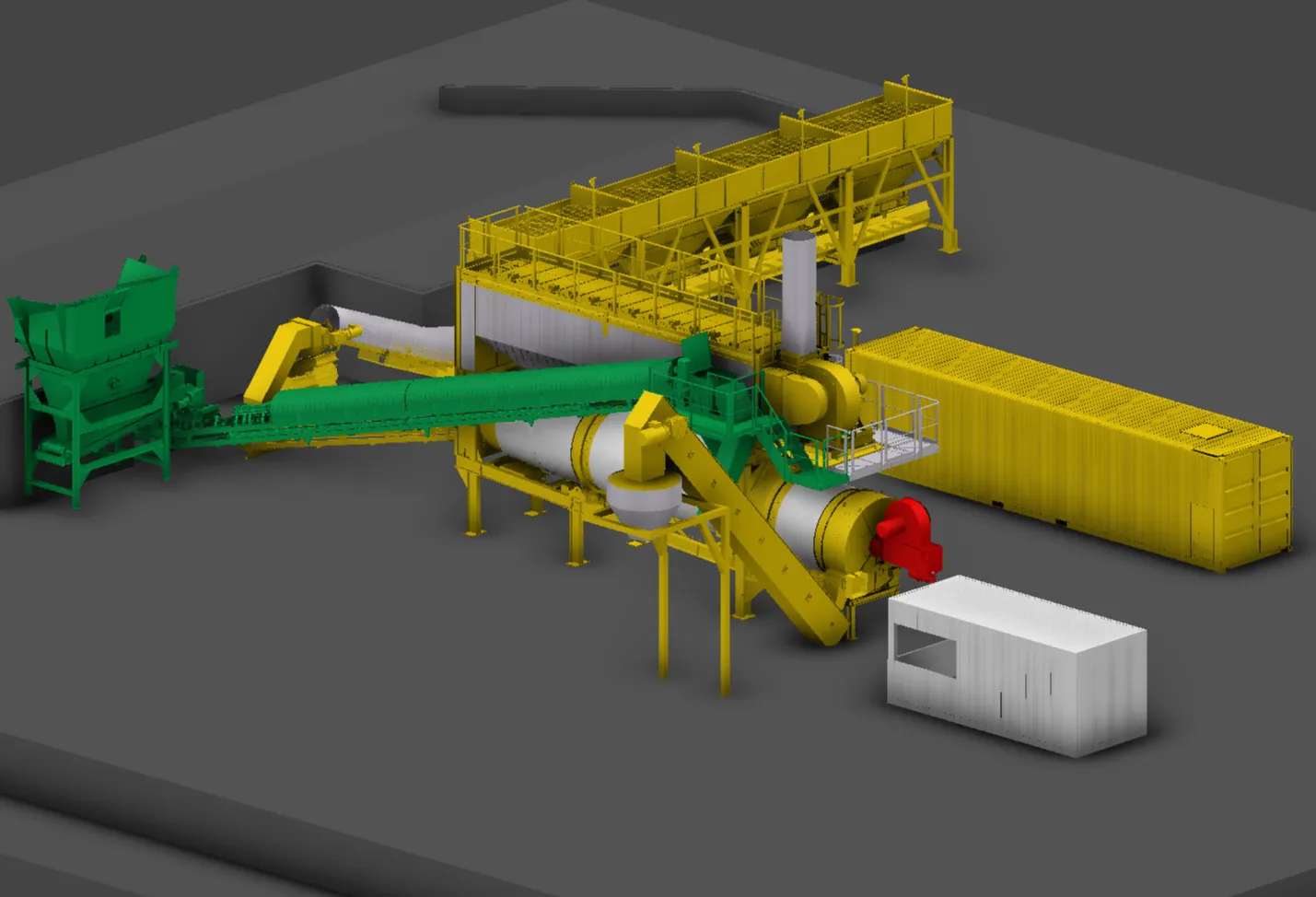

Fayat claims that the use of cutting-edge technology in its Marini-Ermont RF 160 Neo asphalt plant allows contractors to produce high-quality output at low cost. This new-generation, continuous asphalt plant features a modular design. Filippo Baldasari is head of global sales at Fayat Road Equipment and said, “It can be adapted to the needs of the customer.”

This versatile modular system reduces the cost of ownership according to Baldassari and he added, “It’s super transportable requiring a minimum numbe

January 6, 2017

Read time: 3 mins

This versatile modular system reduces the cost of ownership according to Baldassari and he added, “It’s super transportable requiring a minimum number of trucks, it’s quick to erect, it has low energy consumption and it can use up to 50% recycled materials in its feed.”

He said that for customers in Europe the plant can be set up in a highly sophisticated configuration while it can be used in a more basic layout for emergent market needs and added, “We guarantee the same quality of product.

Highly mobile, the continuous asphalt plant suits duties requiring the production of high-quality road-building asphalt, while using large quantities of recycled feed. Other novel features include the design of its stacked filtration and drying units with an extra-short, fully insulated connecting duct and its extra-short fines recycling circuit. This layout is said to ensure high precision flow management. The plant is also said to meet the needs of contractors looking to lower carbon emissions.

The plant benefits from the firm’s advanced ECOdry, ECOdrive, ECOenergy, ECOstart, ECOflame and RECYCLEAN technologies, which help to lower energy consumption. Its output range is from 80-160tonnes/hour and the plant incorporates the firm’s Retroflux technology, featuring a counterflow dryer drum mixer. This configuration allows for the recycling of up to 50% RAP, while reducing the environmental impact. Key features include systems allowing the quick and easy optimisation of drum output, to analyse and manage all types of energy consumption ratios, to reduce material losses at the start and end of production, and that anticipate burner speed.

The modular design of the RF 160 Neo allows it to meet the requirements of customers in European and emergent markets. In its basic version, it can produce conventional asphalt at the lowest possible cost. It can also be equipped with an array of additional equipment that allow it to meet any needs relating to the specificities of worksites. Meanwhile in terms of safety, it already conforms to the revised European standard EN 536, which will soon be published.