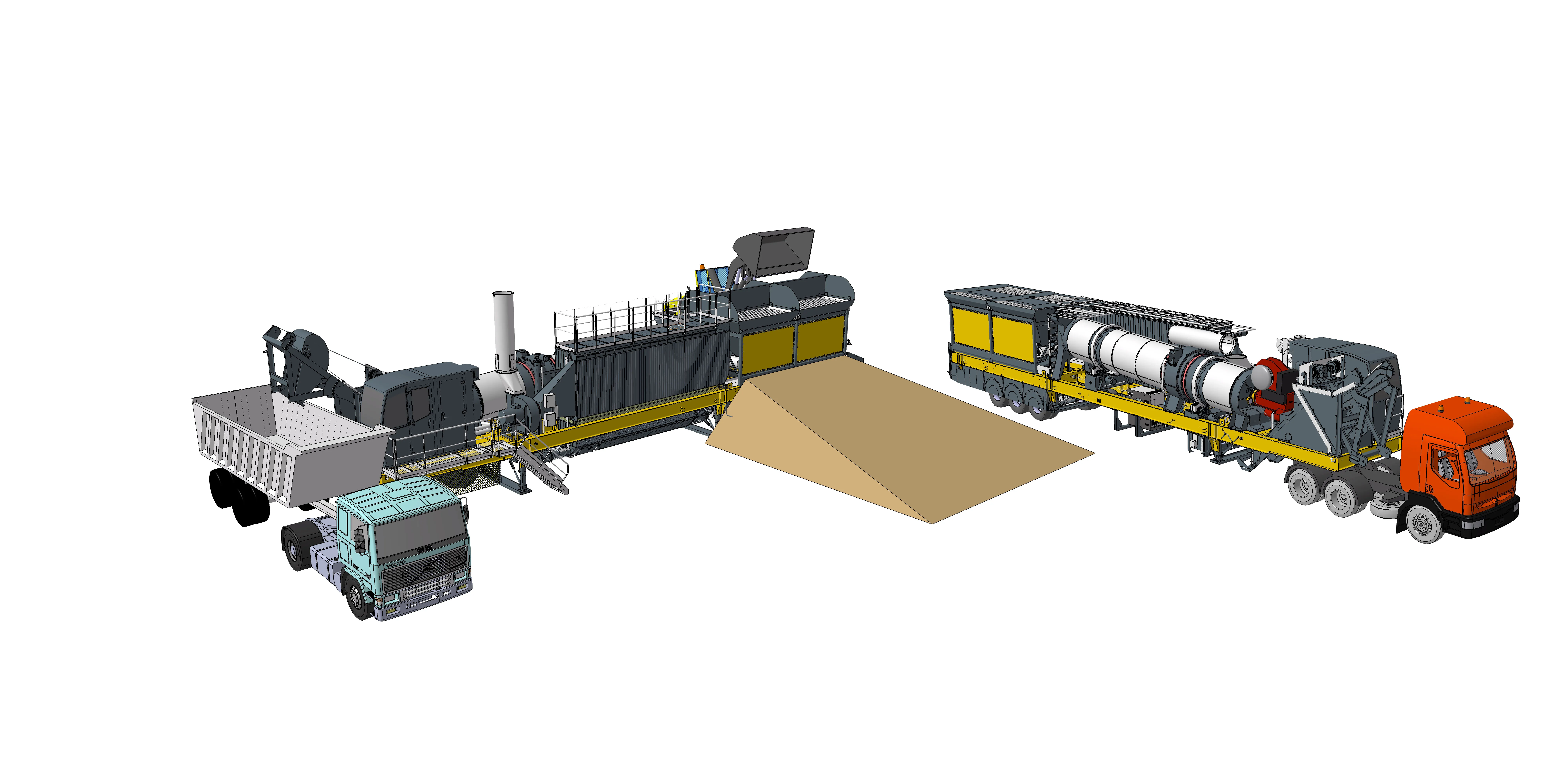

Fayat claims high mobility and versatility for its RM120 ALLROAD plant. This plant is designed for ease of transport and installation onsite and completes the firm’s ROADMASTER range. Communications executive Paola Pezzi said, “It can recycle up to 40% RAP and it can be equipped for warm mix technology. It is suited to small and medium size plants.”

The plant offers an output of 50-120tonnes/hour and the firm says that it can produce high-quality, hot-mix or warm-mix asphalt, with or without recycled mat

January 6, 2017

Read time: 2 mins

The plant offers an output of 50-120tonnes/hour and the firm says that it can produce high-quality, hot-mix or warm-mix asphalt, with or without recycled materials. The plant is equipped with the novel RETROFLUX counter-flow technology and is designed to meet the needs of a wide array of markets. The firm says that the RM 120 ALLROAD features efficient metering systems and offers customers a reliable and easy-to-use asphalt plant. In addition, the plant also offers the possibility of technical upgrades.

This single-unit plant benefitS from good ground clearance and high mobility for its category, which allows customers to operate as close to construction sites.