Topcon positioning group has made improvements to its P-32 asphalt paving system, which aim to give faster, better quality paving. It has added an ST-3 sonic tracker and an anti-vibration slop sensor to the system and updated the GC-35 control box.

March 11, 2014

Read time: 2 mins

"The P-32 paver system was built to improve smoothness, ensure accurate slope and material thickness and provide unmatched operator ease-of-use," said Kris Maas, machine control product marketing manager for Topcon. "The P-32 saves time and improves safety by allowing an operator to view elevation and slope values of the screed from a single control box. With these new components, this state-of-the-art 2d control system will continue to improve the speed and quality of asphalt paving."

The ST-3 sonic tracker will provide higher accuracy in positioning and improves operation in tight areas. "The introduction of the ST-3 sonic tracker will increase productivity for users by providing smoother surface detections," said Maas. “The smoother it can be the fast the job will finish."

The new slope sensor will also add to accuracy and has been designed to cope in a rage of conditions. According to Maas, the sensor is resistant to vibrations and works well within different temperature ranges.

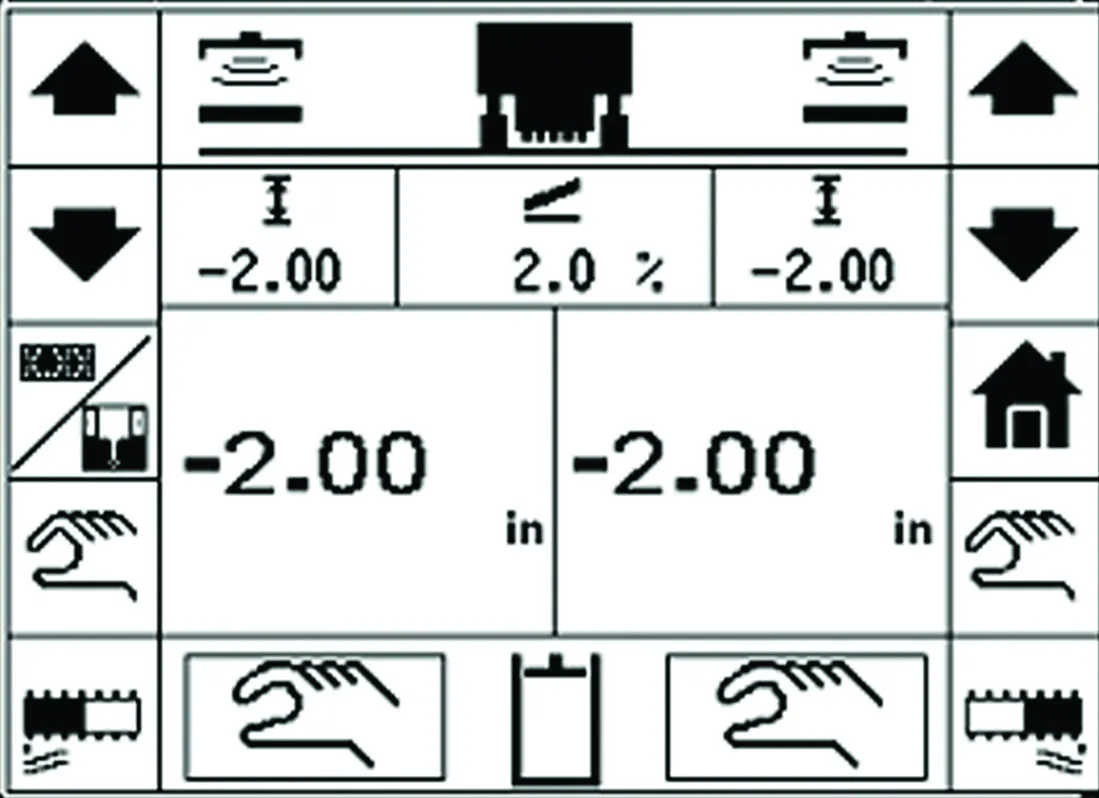

The changes to the control box mean that the Cross slope value will be displayed even when the control box is set in elevation control mode on both sides. "This takes the guess work out of knowing whether the Cross slope is correct. Additionally, block slope calibration protects users from accidently changing the slope sensor while the P-32 system is in operation." said Maas.

www.topconpositioning.com