A new partnership between MWay Communications, Saint-Gobain PAM UK and Stanton Bonna has resulted in an access cover installation that cuts time on site by 50%. The system also improves site safety and ensures high quality standards are met for reduced future maintenance.

The innovative precast concrete motorway communications chamber slab was developed by MWay Communications. The system is now on the market through a joint venture between Saint-Gobain PAM UK and Stanton Bonna to precast the access chamb

July 6, 2016

Read time: 2 mins

A new partnership between MWay Communications, 5475 Saint-Gobain PAM UK and Stanton Bonna has resulted in an access cover installation that cuts time on site by 50%. The system also improves site safety and ensures high quality standards are met for reduced future maintenance.

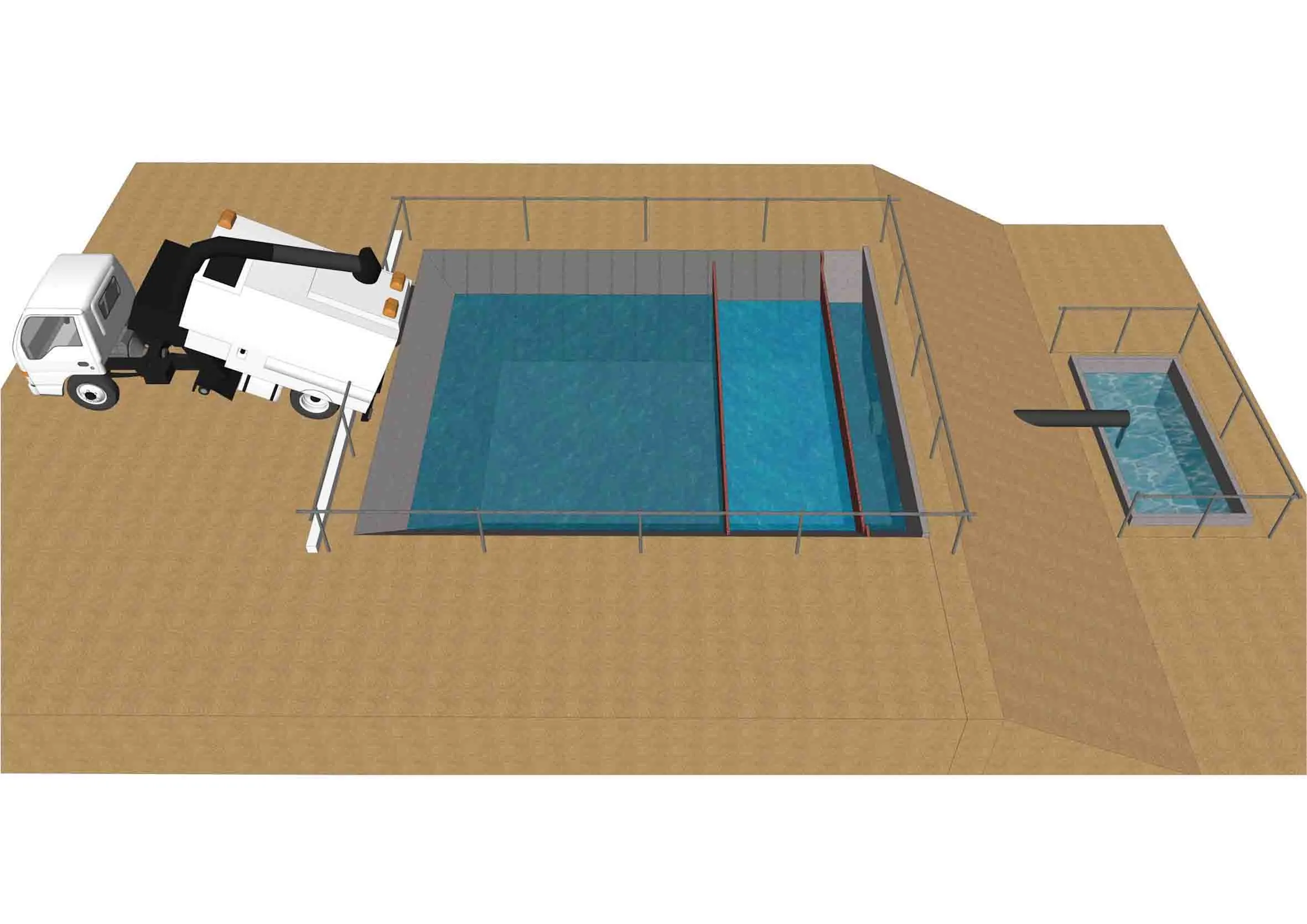

The innovative precast concrete motorway communications chamber slab was developed by MWay Communications. The system is now on the market through a joint venture between Saint-Gobain PAM UK and Stanton Bonna to precast the access chamber cover slab off site. By manufacturing the access chamber slab in a factory, the partners can reduce the time for on-site installation. This makes a major reduction in overall working time.

The on-site installation is reduced to two steps: excavation and installation of the chamber before installing the precast hard standing and completing the earthworks. The installation work can be carried out in virtually all weather conditions. Saving onsite installation time improves efficiency and frees up resources for other tasks, while reducing manual handling and movement of vehicles and people on site, the solution also improves safety.

The patent pending solution combines high-quality steel reinforced precast concrete with Saint Gobain PAMs high-performance ductile iron Opt-Emax access covers and Warrior surface boxes.

Two solutions have initially been developed: an A type chamber cover slab and a smaller B type chamber cover slab. Both have cast-in lifting anchors to aid safe offloading and installation. Once installed the Opt-Emax access cover is designed for frequent maintenance and inspection of below ground assets. The cover sections are individually hinged to reduce lifting effort, it has a skid resistant design and security is provided using Saint-Gobain PAM’s patented T-LOK system.

The innovative precast concrete motorway communications chamber slab was developed by MWay Communications. The system is now on the market through a joint venture between Saint-Gobain PAM UK and Stanton Bonna to precast the access chamber cover slab off site. By manufacturing the access chamber slab in a factory, the partners can reduce the time for on-site installation. This makes a major reduction in overall working time.

The on-site installation is reduced to two steps: excavation and installation of the chamber before installing the precast hard standing and completing the earthworks. The installation work can be carried out in virtually all weather conditions. Saving onsite installation time improves efficiency and frees up resources for other tasks, while reducing manual handling and movement of vehicles and people on site, the solution also improves safety.

The patent pending solution combines high-quality steel reinforced precast concrete with Saint Gobain PAMs high-performance ductile iron Opt-Emax access covers and Warrior surface boxes.

Two solutions have initially been developed: an A type chamber cover slab and a smaller B type chamber cover slab. Both have cast-in lifting anchors to aid safe offloading and installation. Once installed the Opt-Emax access cover is designed for frequent maintenance and inspection of below ground assets. The cover sections are individually hinged to reduce lifting effort, it has a skid resistant design and security is provided using Saint-Gobain PAM’s patented T-LOK system.