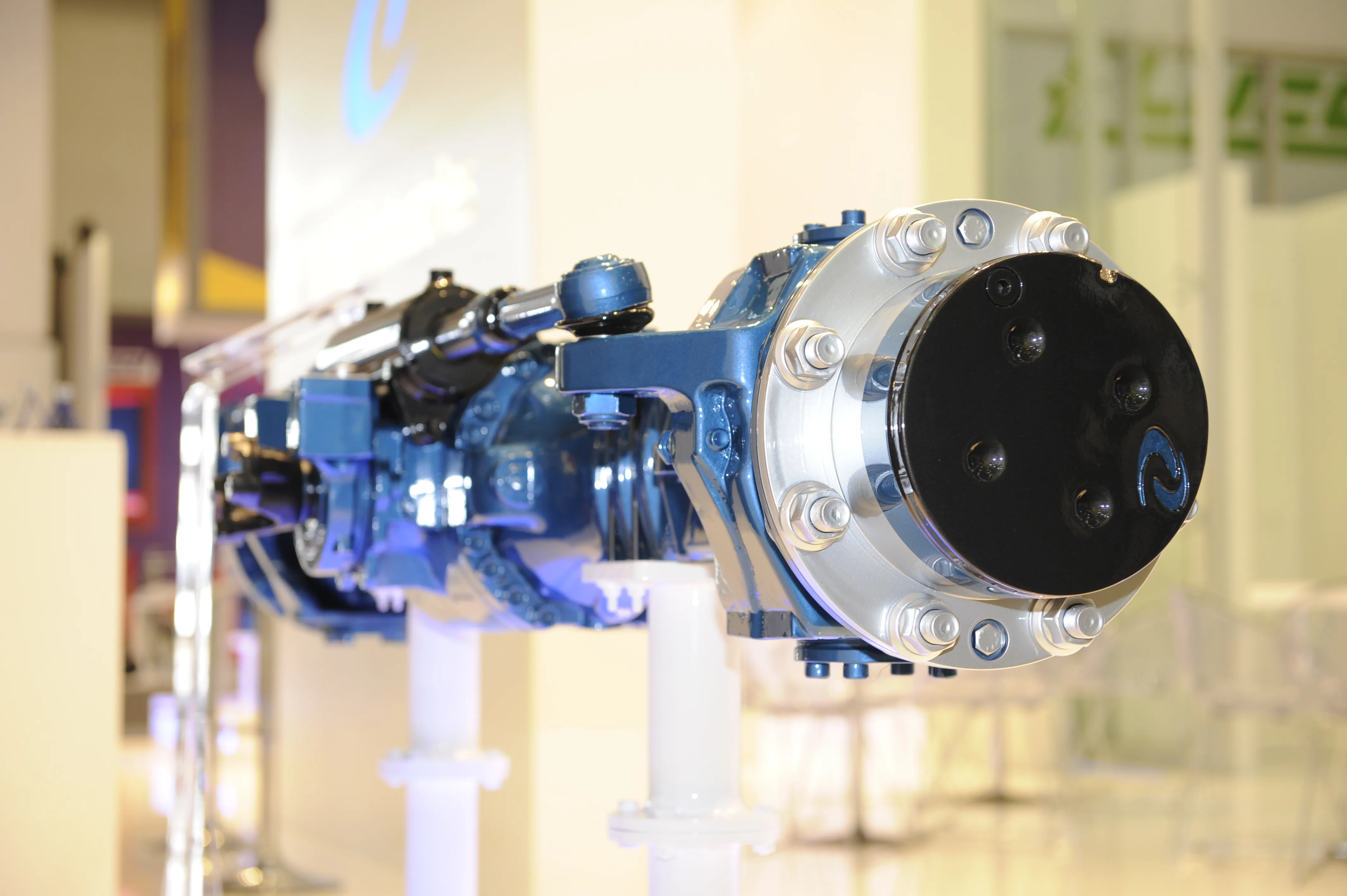

Dynavis, a major additive product from Evonik. helps fine-tune engines, pumps, drive systems and hydraulics.

“A simple change of hydraulic fluid can help save fuel, even—and particularly—in used construction machines,” says Rolf Fianke, technology aftermarket support manager at Evonik.

In Italy, Nuova Ghizzoni, an Italian pipeline contractor, switched its entire fleet of hydraulic excavators to a fluid formulated with Dynavis technology supplied by a Dynavis licensee. The switch was a move away from c

January 6, 2017

Read time: 2 mins

“A simple change of hydraulic fluid can help save fuel, even—and particularly—in used construction machines,” says Rolf Fianke, technology aftermarket support manager at Evonik.

In Italy, Nuova Ghizzoni, an Italian pipeline contractor, switched its entire fleet of hydraulic excavators to a fluid formulated with Dynavis technology supplied by a Dynavis licensee. The switch was a move away from conventional single-grade and multigrade oils.

Evonik says it has also teamed up with several global partners, including the French mineral oil multinational

The Dynavis brand doesn’t represent a hydraulic fluid, but rather a technology, and a complete package of formulation support and global services, using an additive that improves the viscosity index of hydraulic fluids. Evonik claims that fuel savings of up to 10% are achievable, with up to 30% under extreme loads.

All videos