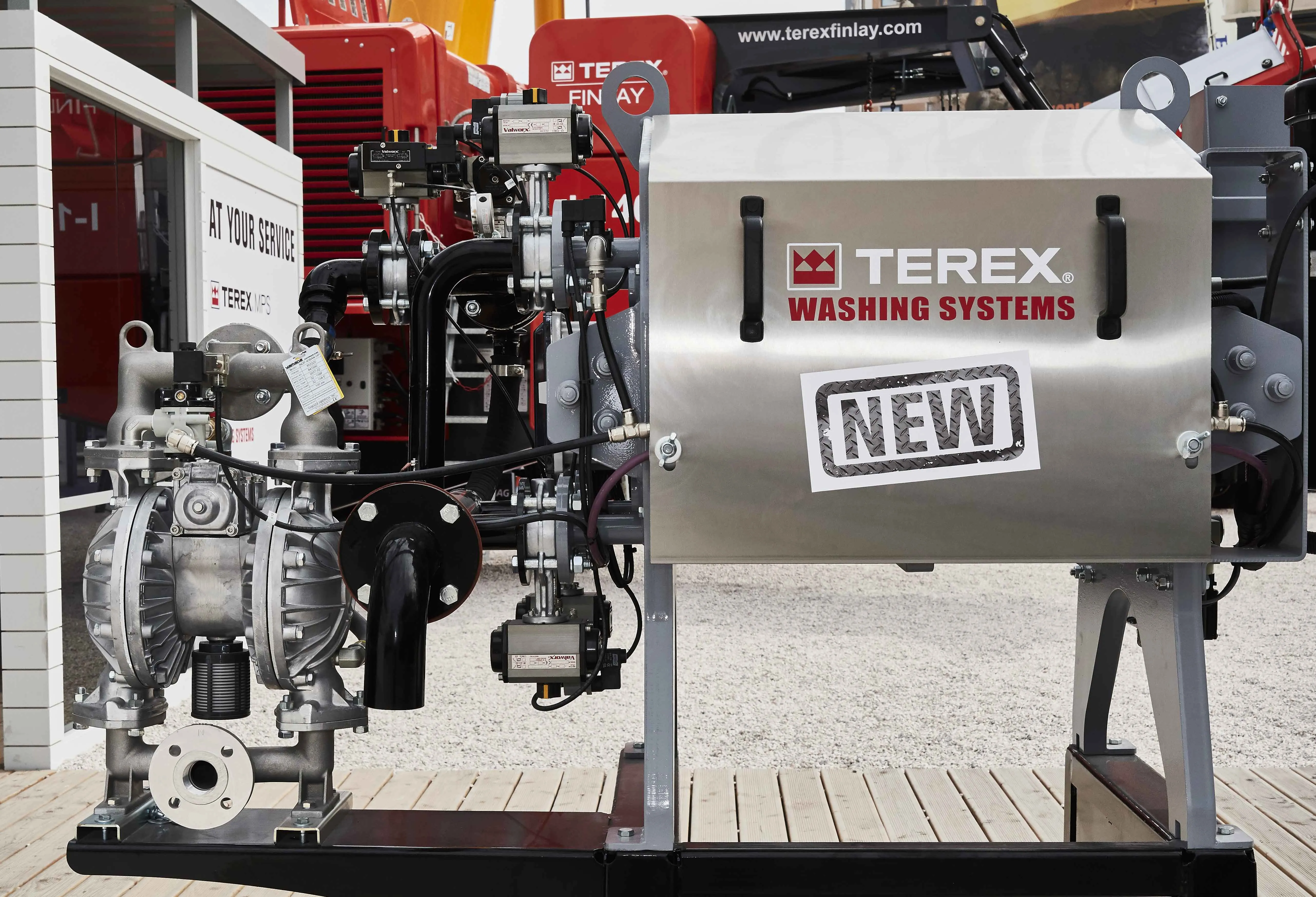

Terex Washing Systems (TWS) has staged the global launch of Terex AquaClear Water Management Solutions at CONEXPO-CON/AGG 2017.

Oliver Donnelly, TWS global business line director, said: ‘It really is an exciting time for TWS and we are delighted to be able to offer an end-to-end solution for washing and water management from TWS, a single supplier. We are launching a full range of water management products to include clarifying tanks, flocculent dosing systems, filter presses and all associated equipment

March 11, 2017

Read time: 3 mins

Oliver Donnelly, TWS global business line director, said: ‘It really is an exciting time for TWS and we are delighted to be able to offer an end-to-end solution for washing and water management from TWS, a single supplier. We are launching a full range of water management products to include clarifying tanks, flocculent dosing systems, filter presses and all associated equipment to provide a one-stop solution.

A lot of our customers are into water management. It’s a growing sector given the way environmental legislation is headed in certain regions and territories.”

Water Management Solutions are made up from three main components; a floc dosing plant and thickener tank can be used to recycle up to 80% of the water used in the washing process. This basic method still involves the use of ponds but on a smaller scale as the sludge sent to the ponds is of a much higher specific gravity (1.5sg). The next stage is to incorporate a filter press which hydrates this thickened even further typically down to 25% moisture. The filter press eliminates the need for ponds as the sludge is hydrated to a material/cake which can be handled by a loading shovel. This cake can be used as a lining or capping material.

TWS said the brand is committed to continuous expansion of its product offering and this entry into Water Management demonstrates its continued significant investment in product development, which once again raises the bar in adding value to its customers operations.

Donnelly said TWS was due to begin manufacturing the Terex AquaClear Water Management Solutions in Dungannon, Northern Ireland later this year, working alongside strategic alliance partners, Valley Equipment Company (VEC), located in Portland, Oregon.

“We’re handling enquiries for AquaClear from Europe and North America. I think it’s likely that the first installation will be a European one.

Through our strategic alliance, [for North American customers] we can send a filter press fully built up, rather in its component parts in containers. With Valley Equipment, we’re working with partners who have been in the industry years and years,” added Donnelly.

TWS is also investing in a focused technical team to support the new Terex AquaClear Water Management offering. The Terex brand is appointing a dedicated team consisting of a product manager, engineers and applications specialists together with a cutting edge new laboratory specifically designed for material testing and sample pressing. This will ensure optimum equipment selection and specification for its customers.

Already a leading established supplier of advanced wet processing solutions for mineral washing needs in aggregates, recycling, industrial sands & mining, TWS offers an extensive product portfolio to match the needs of rinsing, scrubbing and sand production systems available in static, modular and mobile platforms.