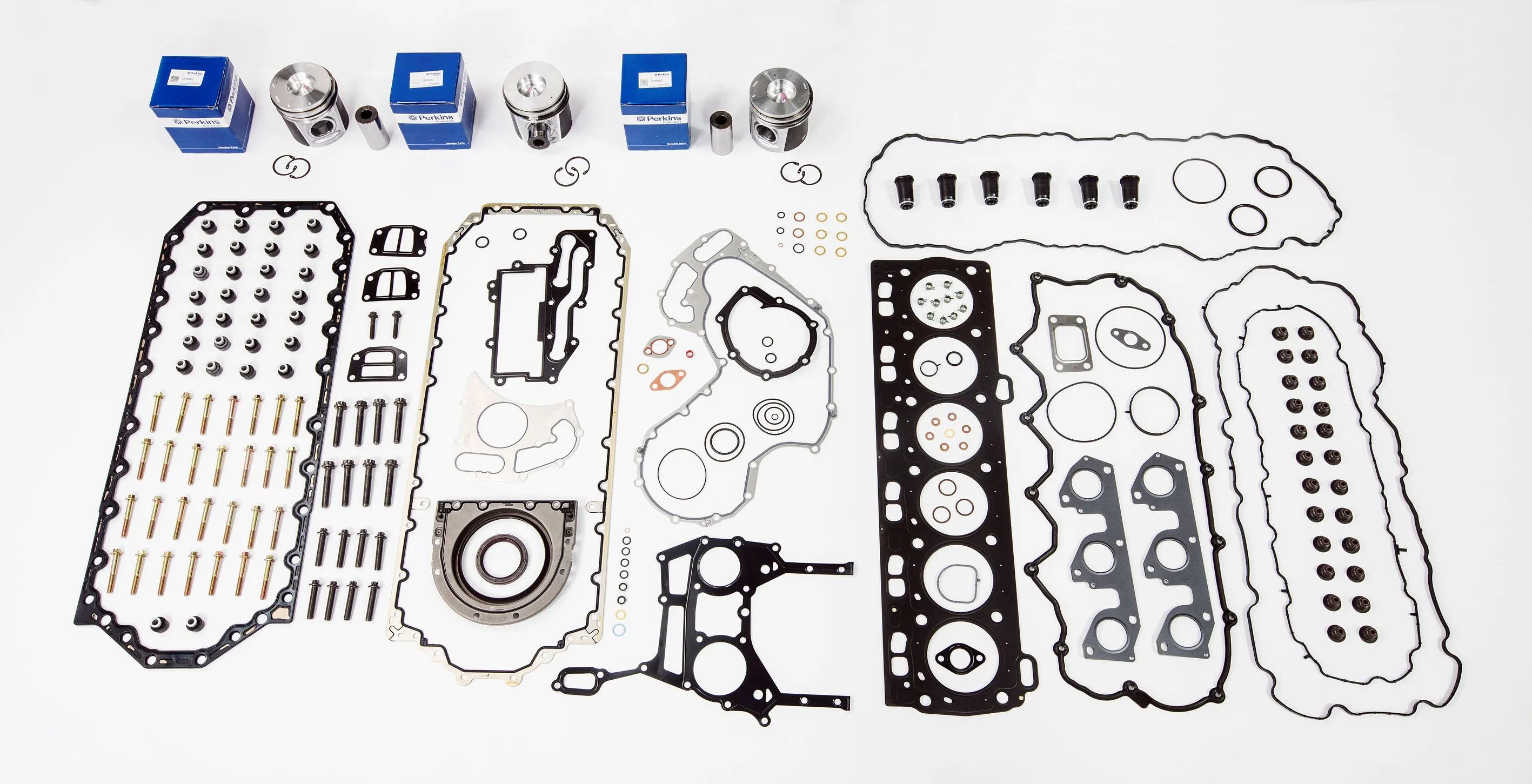

To simplify parts ordering for engines that require an overhaul,

“For example, these include gasket kits, overhaul kits, bearing kits and valve train kits,” explained Siobhan Scott, marketing manager for Perkins’ aftermarket division. “And kits can be combined in numerous ways to provide a cost-effective solution to support major overhauls.”

As an alternative to overhauling an engine, particularly if machine downtime comes at a high cost, customers can also choose to purchase a replacement engine. There are over 350 replacement engine options available, and include long blocks, short blocks and complete cylinder heads, all as remanufactured and new options - the latter providing a drop-in solution.

In addition, a range of new, remanufactured or ‘new-for-old’ turbocharger options are now available from Perkins.