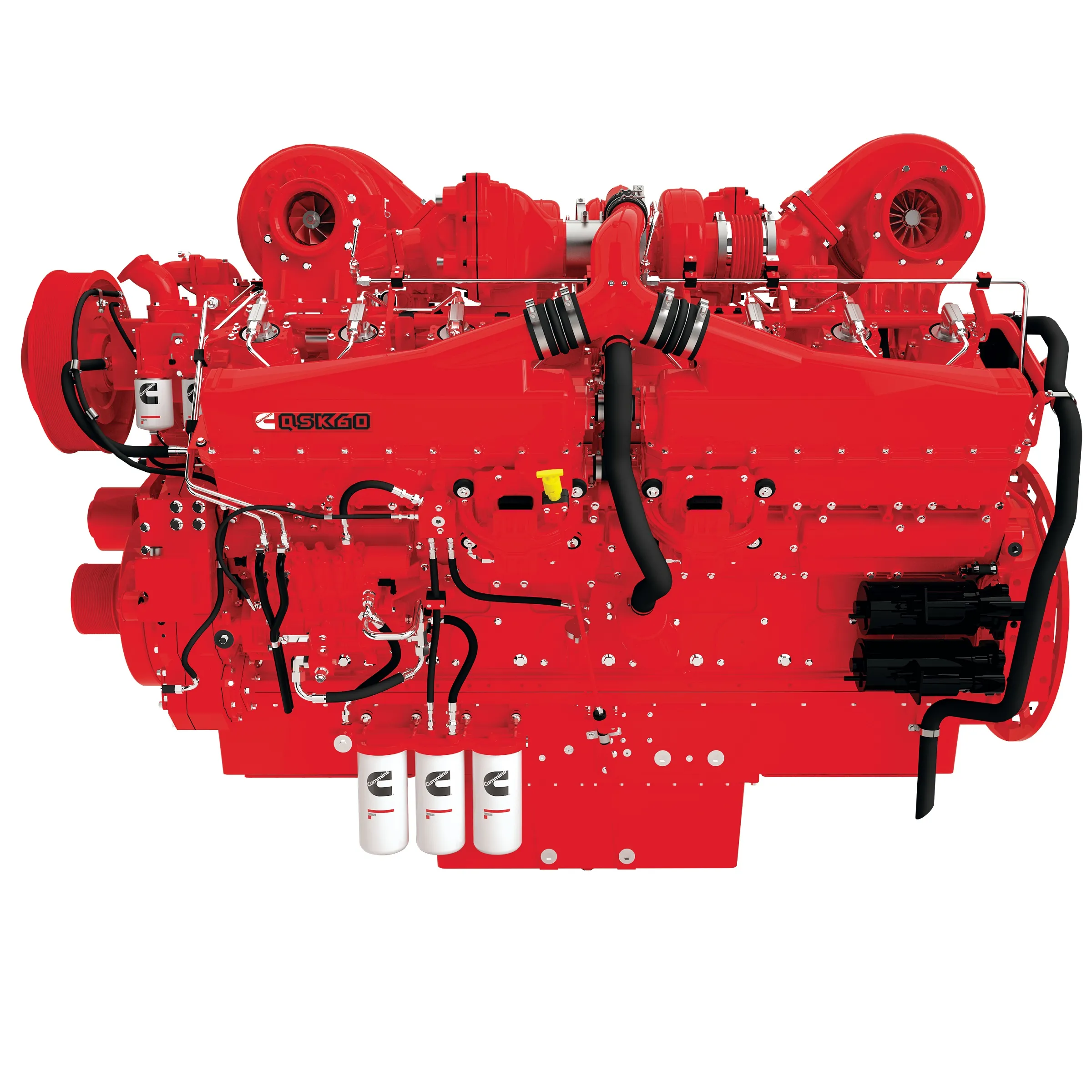

Cummins invested US$10 million in its Master Rebuild Centre in Krakow, Poland. This has allowed European customers to arrange a rebuild or full-scale remanufacture of a high-power Cummins engine to original equipment standards, supported by the firm’s warranties.

The remanufacturing option is available in three packages and is for engines with capacities from 19-78litres that require more than a conventional in-chassis rebuild. “We now have a solution in Europe for every situation in the lifecycle of a high horsepower Cummins engine,” said Alan Routledge, Manager – New Business Start-up Leader.

Taking a proactive approach to engine maintenance can save customers on repair costs. At Krakow, Cummins offers three remanufacturing packages –Advanced, Ultimate and Ultimate SE (Service Exchange). Advanced has a standard bill of materials and warranty coverage to help keep the costs down for customers.

The next level up is Ultimate, which is a zero hour remanufacture where the life-to-overhaul expectation is the same as a brand new engine and the work is backed by a 12-month unlimited or two-year/2,000 hours warranty which may also include Cummins pro-rata policy coverage beyond warranty.

With Ultimate, the engine is completely dismantled and individual parts are cleaned with advanced tools, techniques and solvents to remove debris without degrading metal surfaces. All parts are inspected and replaced if necessary. Following reassembly, the engine is dyno-tested to ensure expected power and torque performances are met, along with in-test spectrum oil analysis.

Remanufacturing takes around 35 days and Routledge said, “It’s less expensive, and there’s an environmental benefit because remanufacturing requires around 85% less energy than manufacturing new engines.” Attached to the Ultimate package, providing it is planned with at least four months’ notice, there is the option of a service exchange (SE) engine unit. There is a fixed price on the Ultimate and Ultimate SE packages on condition of the returned engine core being complete with no evidence of misuse.