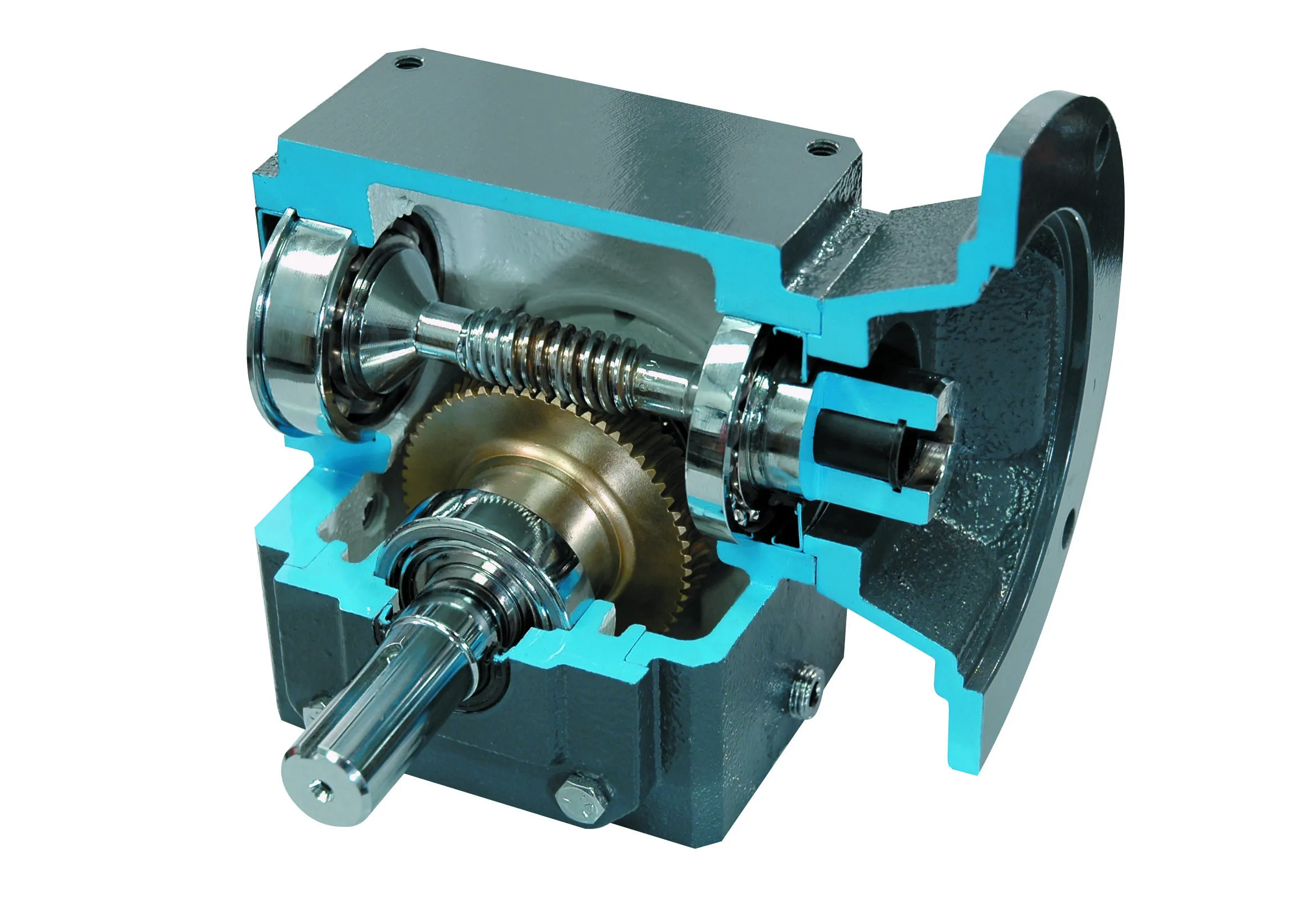

From Emerson Industrial Automation come a novel worm gear reducer that is leak-free for 18 months. The patented Morse Raider Plus has a roll-burnished seal journal and double-lip seals, designed to keep contaminants out and lubrication in. A quill liner system is fitted to make disassembly less of a challenge. The product is said to be ideal for use in conveyors, mixers and bucket elevators. The computerised gear centering optimises the gear mesh for reduced heat and debris formation, eliminating backlash a

January 17, 2014

Read time: 2 mins

From 7568 Emerson Industrial Automation come a novel worm gear reducer that is leak-free for 18 months. The patented Morse Raider Plus has a roll-burnished seal journal and double-lip seals, designed to keep contaminants out and lubrication in. A quill liner system is fitted to make disassembly less of a challenge. The product is said to be ideal for use in conveyors, mixers and bucket elevators. The computerised gear centering optimises the gear mesh for reduced heat and debris formation, eliminating backlash and delivering high efficiency and long life. A patented roll-burnished journal finish extends seal life, while novel double-lip seals on input and output shafts provide leak-proof operation in highly contaminated applications. The Raider Plus also features an exclusive non-metallic quill liner that reduces fretting and corrosion, and eases motor removal. Large, single-row ball bearings absorb radial and thrust loads on higher input speeds, while heavy-duty tapered roller bearings on all output shafts handle inherent gear load and provide maximum overhung load capacity.

Four variants are offered. The U is a universal type with an output shaft, while the Q has a c-face with an output shaft. Both variants are offered with hollow outputs. All Raider Plus housings, motor adaptors, covers and mounting bases have cast iron single-piece construction for strength and dependability. Forged bronze worm gears, precision manufactured to AGMA specifications, provide greater tensile strength than cast bronze. The integral worm and shaft are hardened to 58RC for extra strength and durability. The speed reducers are all factory-filled with FDA-approved polyglycol synthetic lubricant for enhanced rating and reduced thermal rise.

%$Linker:2 Asset <?xml version="1.0" encoding="utf-16"?><dictionary /> 2 91832 0 oLinkExternal www.EmersonIndustrial.com Emerson Industrial Automation web false /EasySiteWeb/GatewayLink.aspx?alId=91832 false false %>

Four variants are offered. The U is a universal type with an output shaft, while the Q has a c-face with an output shaft. Both variants are offered with hollow outputs. All Raider Plus housings, motor adaptors, covers and mounting bases have cast iron single-piece construction for strength and dependability. Forged bronze worm gears, precision manufactured to AGMA specifications, provide greater tensile strength than cast bronze. The integral worm and shaft are hardened to 58RC for extra strength and durability. The speed reducers are all factory-filled with FDA-approved polyglycol synthetic lubricant for enhanced rating and reduced thermal rise.

%$Linker: